Regeneration control system and regeneration control method for organic waste gas adsorption device

An adsorption device and regeneration control technology, applied in chemical instruments and methods, combustion methods, separation methods, etc., can solve problems such as high operating costs, large fluctuations in the concentration of regeneration exhaust gas, and uneven regeneration, so as to improve anti-clogging performance and solve Uneven regeneration and reduced running resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

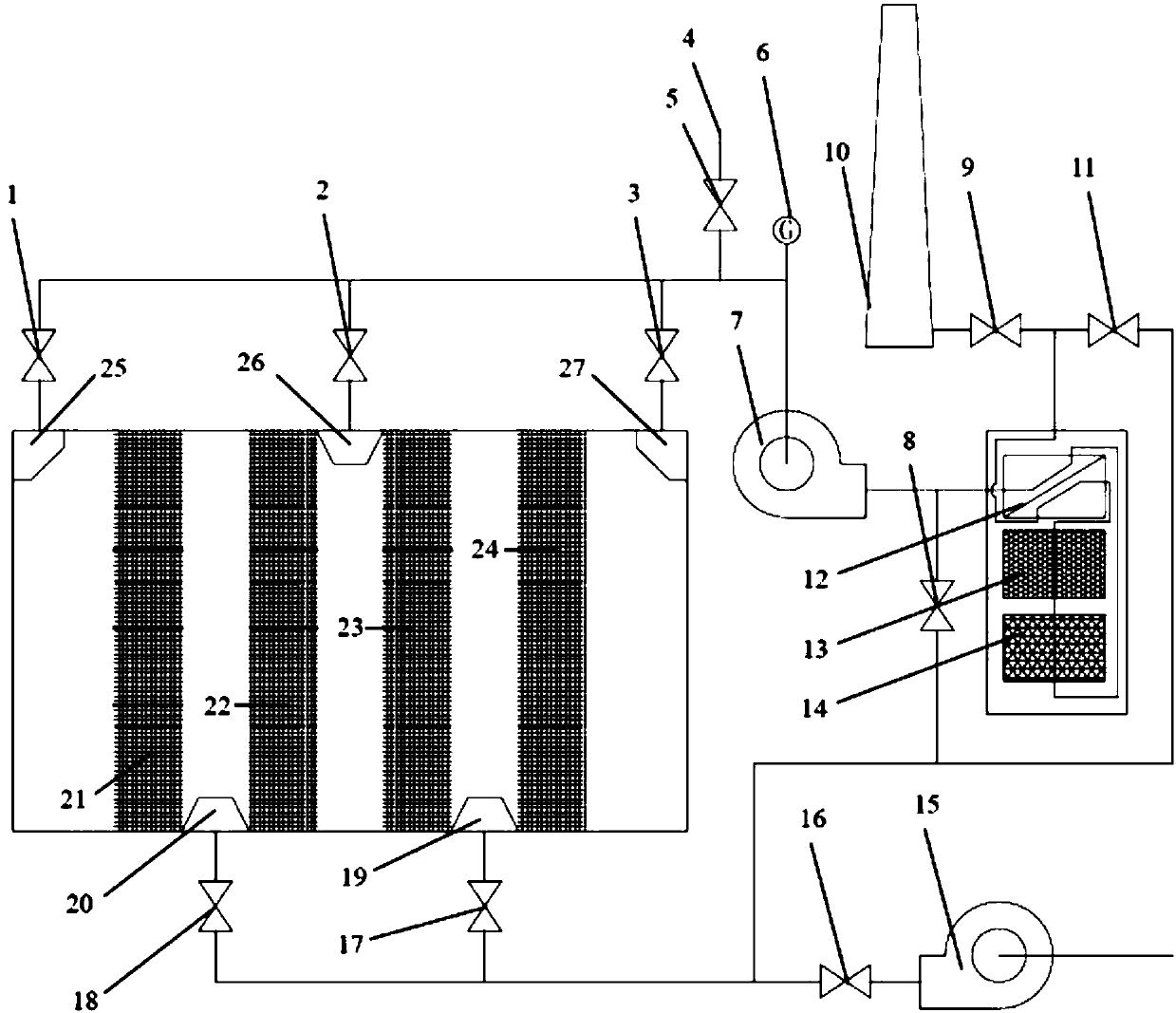

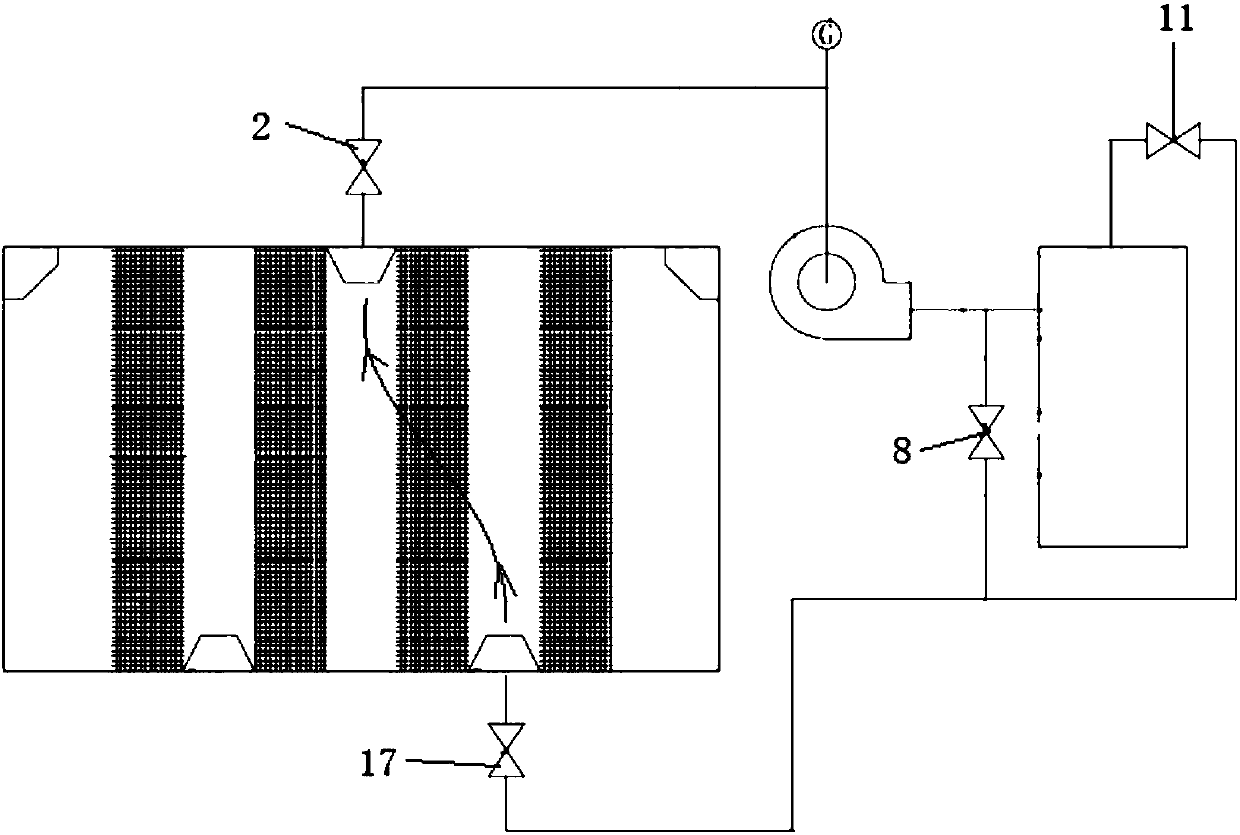

[0054] see figure 1 , the regeneration control system of an organic waste gas adsorption device in the illustration is the preferred solution of the present invention, specifically including the first regeneration return air valve 1, the second regeneration return air valve 2, the third regeneration return air valve 3, the dilution air return valve Air inlet 4, dilution air valve 5, combustible gas concentration detector 6, regeneration fan 7, heat distribution valve 8, discharge valve 9, chimney 10, regeneration air volume control valve 11, catalytic combustion device, supplementary cooling fan 15, supplementary cooling air valve 16. The first regenerative air supply valve 17 and the second regenerative air supply valve 18 .

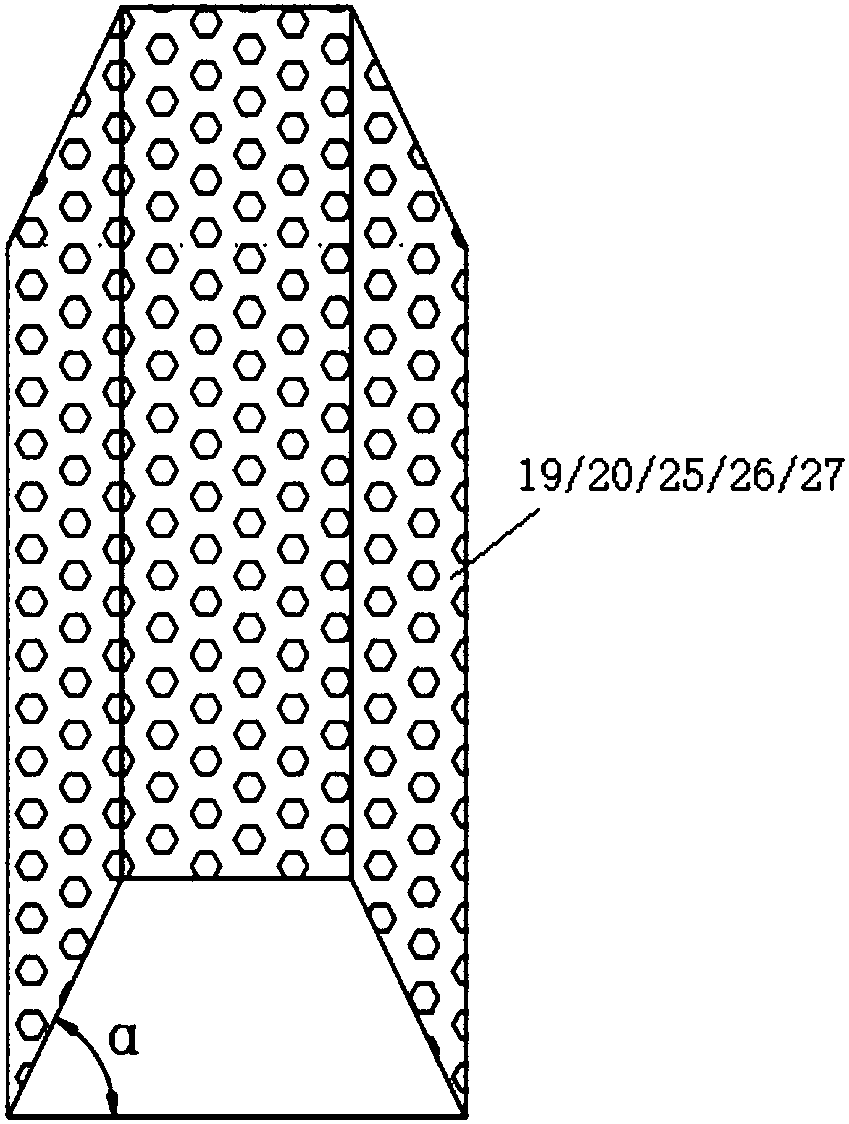

[0055] Among them, the internal adsorbent of the exhaust gas adsorption device is arranged in four layers at intervals, and the four regeneration areas are arranged in parallel with the inner walls on both sides of the exhaust gas adsorption device box....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com