Manufacture method for prestress steel-concrete combined bridge

A technology of prestressed steel and manufacturing method, which is applied in the direction of bridges, bridge construction, bridge parts, etc., can solve the problems of not clearly proposing the preload, low efficiency of bending moment amplitude modulation, and no play, so as to reduce the tensile stress and solve the problem of Stress concentration at the interface and the effect of increasing the tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] In the following, the present invention will be further described in conjunction with the accompanying drawings and specific embodiments, so as to understand the technical idea claimed by the present invention more clearly.

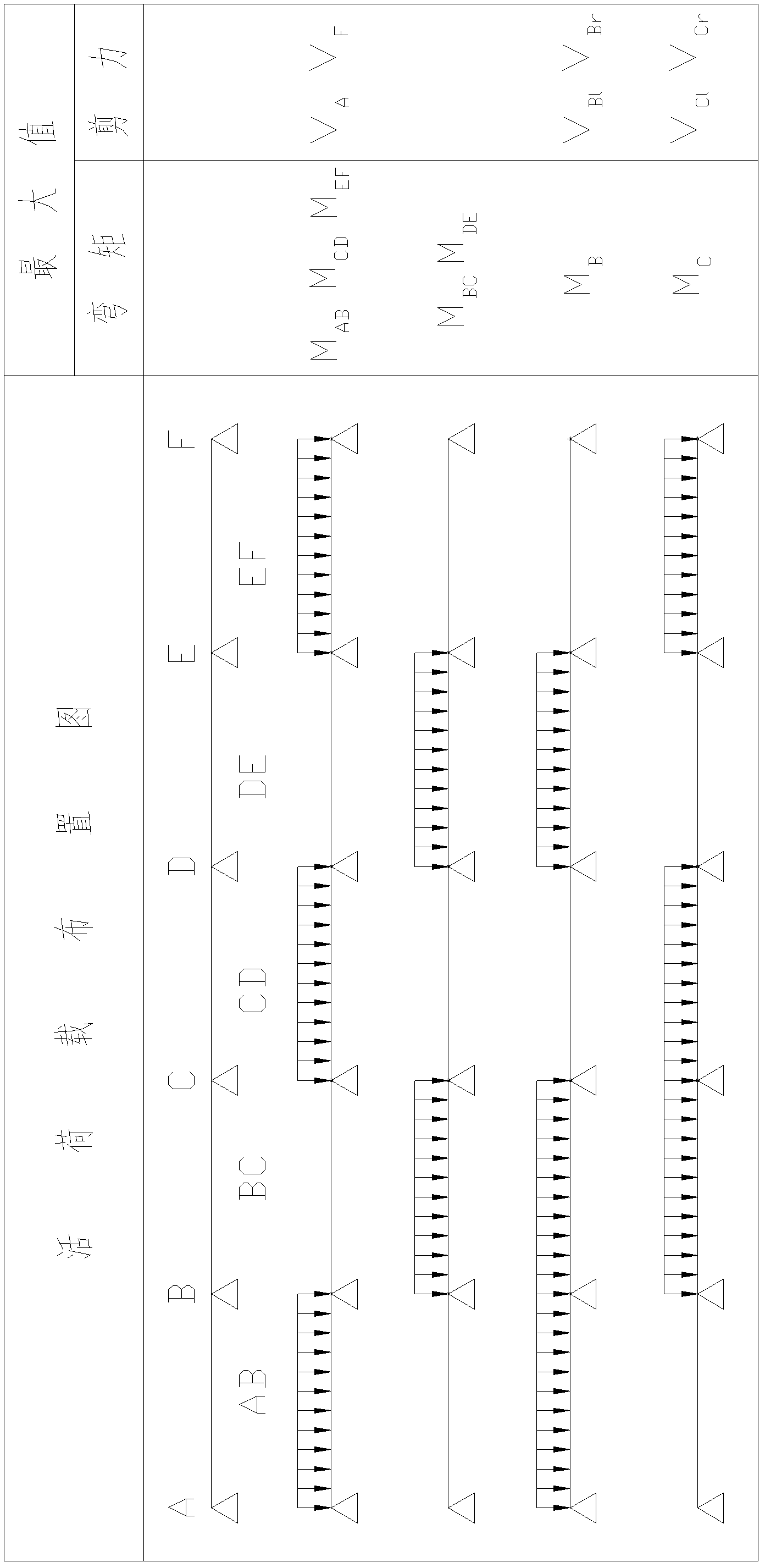

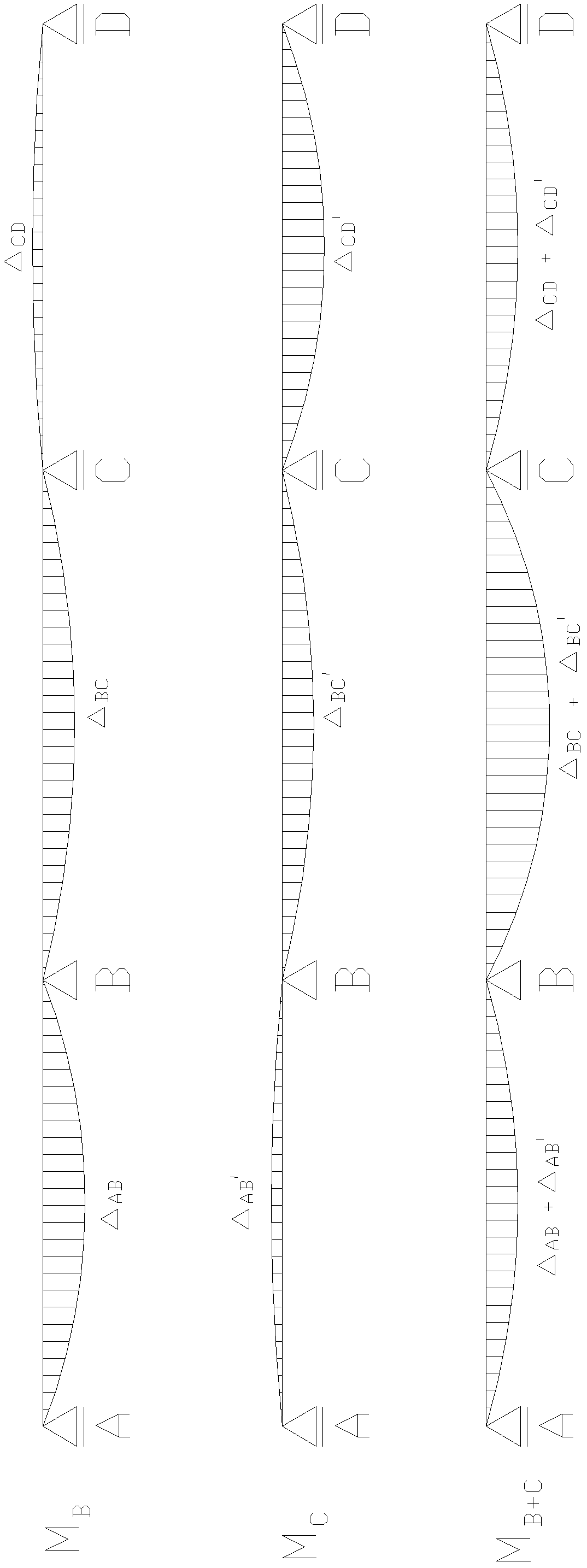

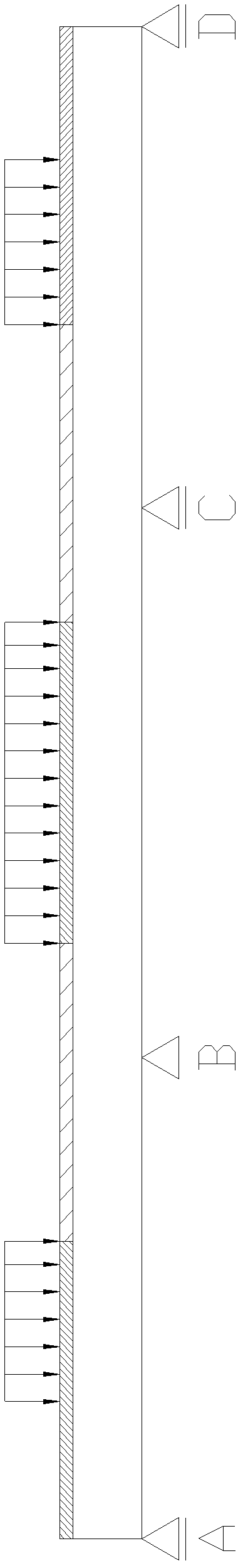

[0039] For ease of review, first, combine Figure 1 to Figure 4 , introduce the architectural theory on which the present invention is based. Calculation of the influence line and the most unfavorable live load position is well known to those skilled in the art. The innovation of the present invention is to use the influence line and the most unfavorable live load position to accurately and quantitatively load the preloaded counterweight.

[0040] Such as figure 1 As shown, it is the live load arrangement diagram of five-span continuous beams. It can be seen from the figure that the live load is arranged on this span and the live load is arranged on every other span, so that the maximum positive bending moment value in a span can be obtained; live...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com