Reinforcement protective structure of large spoil disposal area in mountainous area

A large-scale technology for dregs dumps, which is applied in the field of reinforcement and protection structures for large dregs dumps in mountainous areas, to achieve good environmental protection, simple construction technology, and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

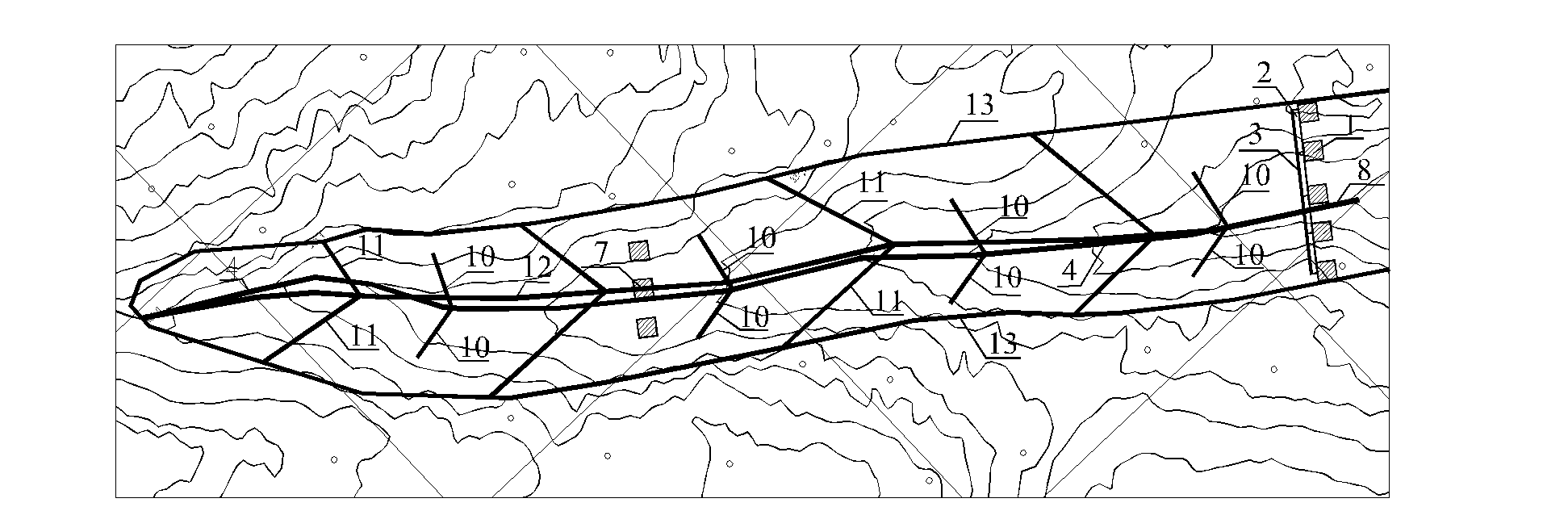

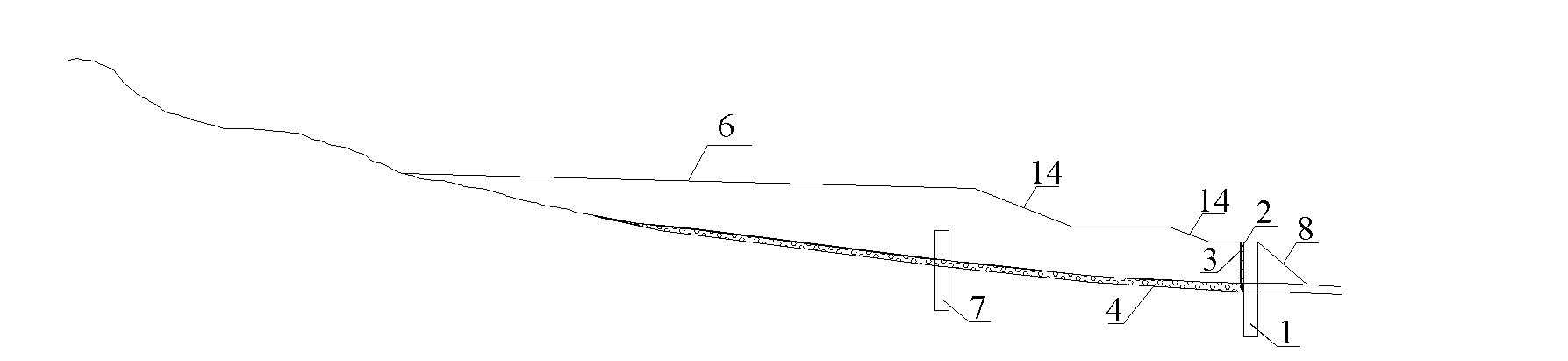

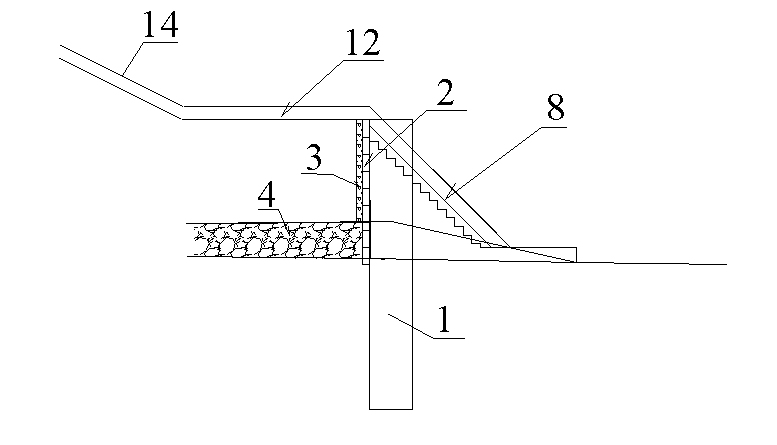

[0016] refer to figure 1 and figure 2 , the reinforcement and protection structure of the large-scale dregs field in mountainous area of the present invention comprises: anti-slide pile 1, is arranged on the foot of slope of the outlet of the muck field, and is arranged at intervals along the transverse direction of the groove; On the side of the field; the gravel anti-filter layer 3 is filled behind the earth retaining plate 2; the main seepage blind ditch 4 is arranged longitudinally along the center of the ditch at the bottom of the dregs dump; the branch seepage ditch 10 is arranged along the center of the ditch at the bottom of the dregs dump Arranged in the form of branches on both sides of the hillside, connected with the main seepage blind ditch 4; the annular intercepting ditch 13 is arranged along the surrounding mountains above the top el...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Depth | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com