Full parameter detection apparatus of polished surface quality of optical element and detection method thereof

A technique for polishing surfaces, optical components, used in the use of optical devices, measuring devices, polarization-influenced properties, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

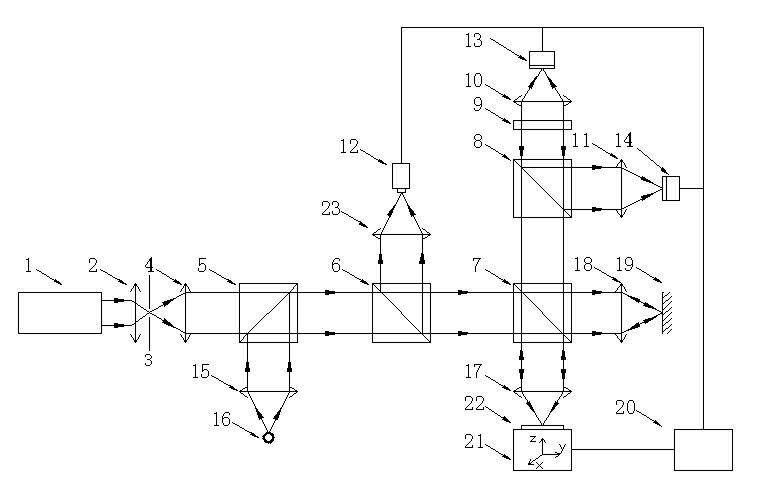

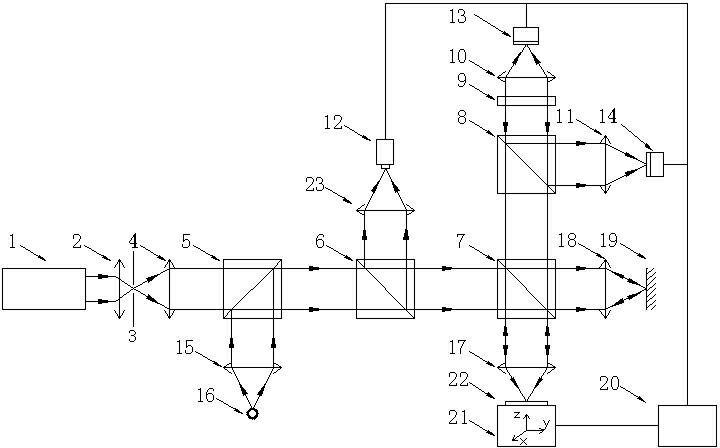

[0022] The present invention will be further described below in combination with specific embodiments and accompanying drawings.

[0023] A full-parameter detection device for polishing surface quality of optical components, including a light source excitation system composed of a laser excitation system with a vertical optical path and a broadband light source 16 excitation system, a white light interference system, a laser confocal detection system, a computer, and CCDs connected to the computer respectively Camera 12, pinhole photodetector and signal processing unit 13, aperture photodetector and signal processing unit 14, and three-dimensional scanning and control unit 21; the white light interference system is arranged between the broadband light source 16 excitation system and the CCD camera 12 The laser confocal detection system is set between the laser excitation system, the pinhole photodetector and the signal processing unit 13, the aperture photodetector and the sign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com