Ultrasonic C-scanning localization method and device

A scanning positioning and ultrasonic technology, which is used in measurement devices, material analysis using sonic/ultrasonic/infrasonic waves, instruments, etc., can solve the problem of low positioning speed, and achieve high positioning speed, high speed and convenient use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below by specific embodiment:

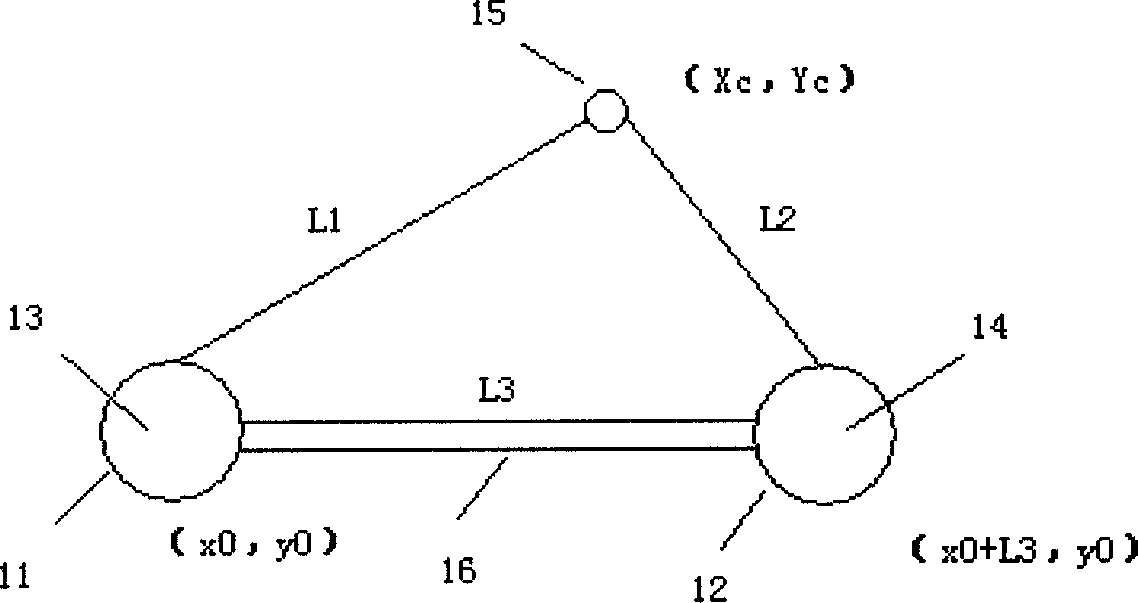

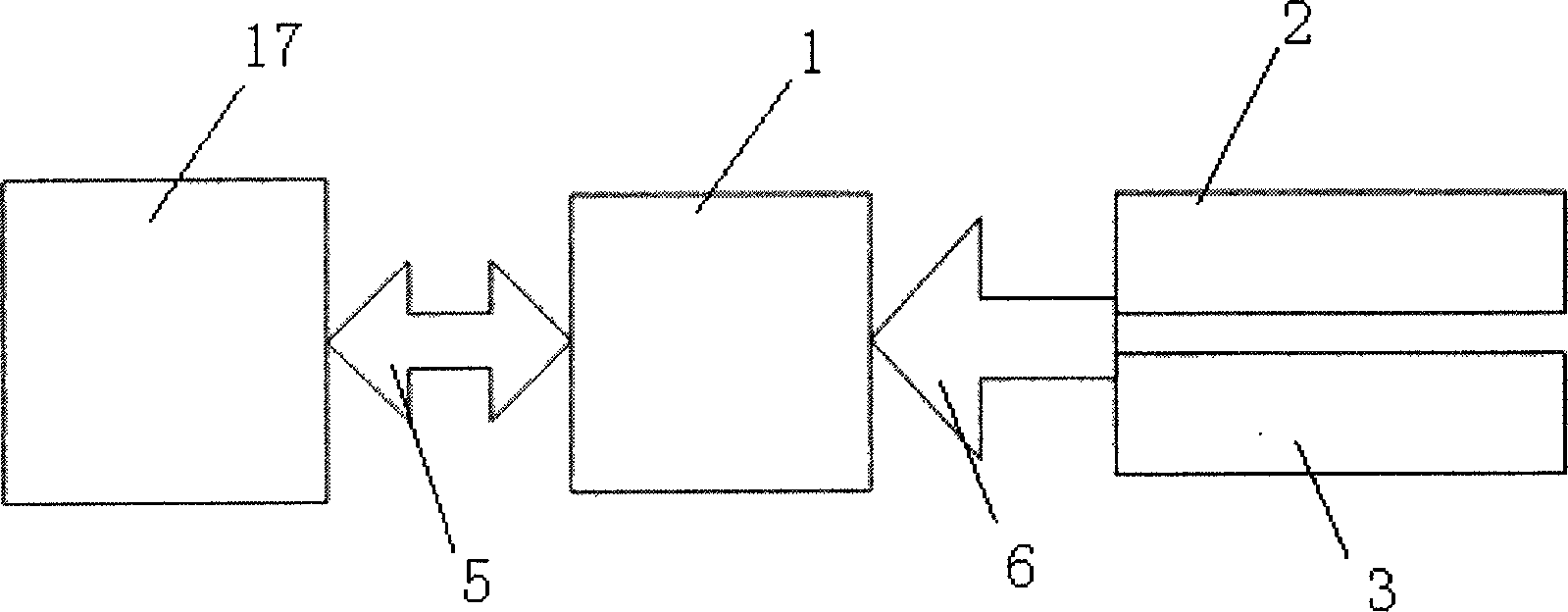

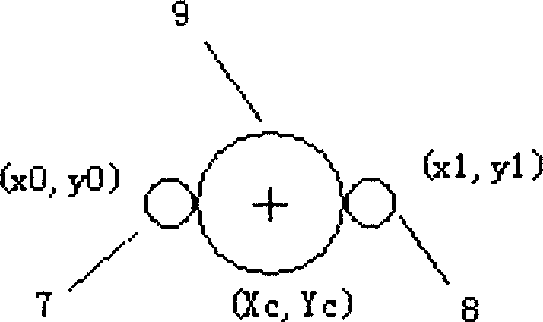

[0029] see figure 2 , which is a system block diagram of the ultrasonic C-scan positioning device of the present invention. The ultrasonic C-scan positioning device includes a CPLD system 1 , a two-way laser sensor circuit 2 , a probe fixture 4 , a communication interface 5 and a serial interface 6 . The CPLD system 1 is EPM3256, which has 4 adders inside. The laser sensor circuit is composed of ADNS9500 laser sensor and surrounding related components, which is used to detect the position change information of the laser sensor itself in real time and send it to the CPLD system. Wherein, the two-way laser sensor circuits are fixed on the probe fixture 4 , and the two-way laser sensor circuits are connected to the CPLD system 1 through the serial interface 6 . The CPLD system 1 is connected with the upper computer 17 through the communication interface 5 to realize the communication with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com