Joint and/or bearing assembly having an elastic intermediate layer

A bearing device and articulation technology, applied in the direction of flexible bearings, shafts and bearings, sliding contact bearings, etc., can solve problems such as deterioration and wear of joint performance, and achieve the effect of simplified assembly, high flexibility, and avoidance of tearing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

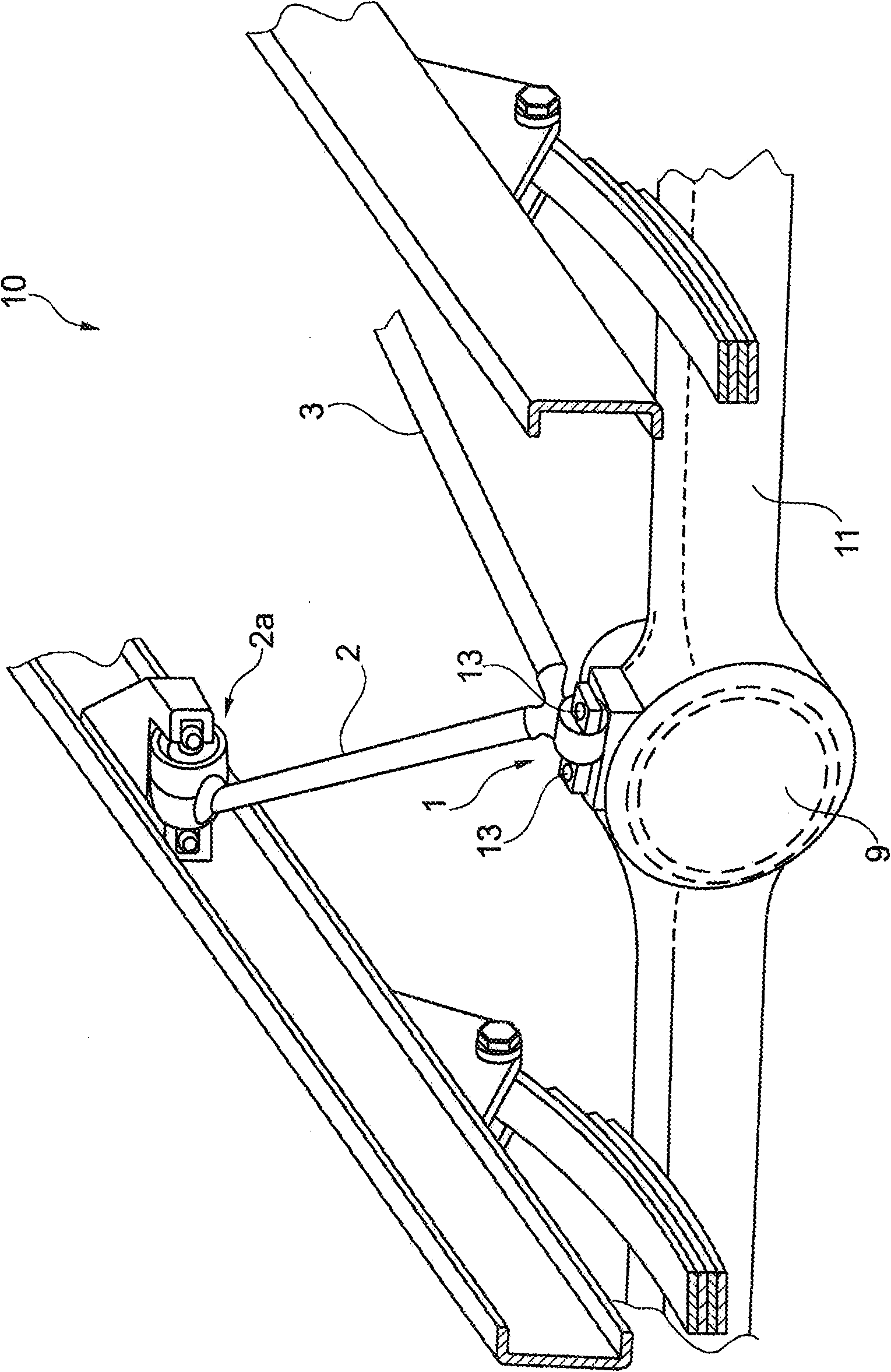

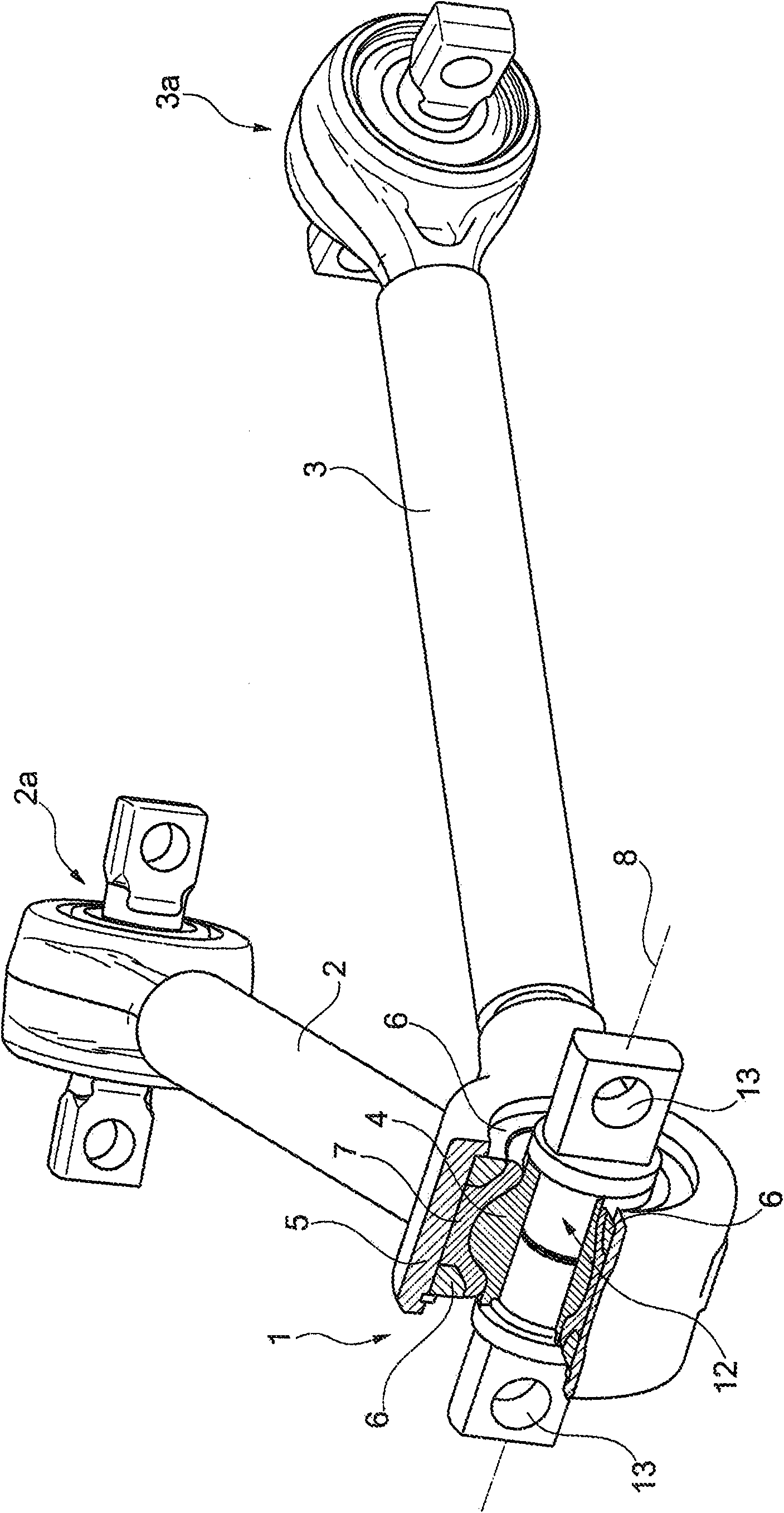

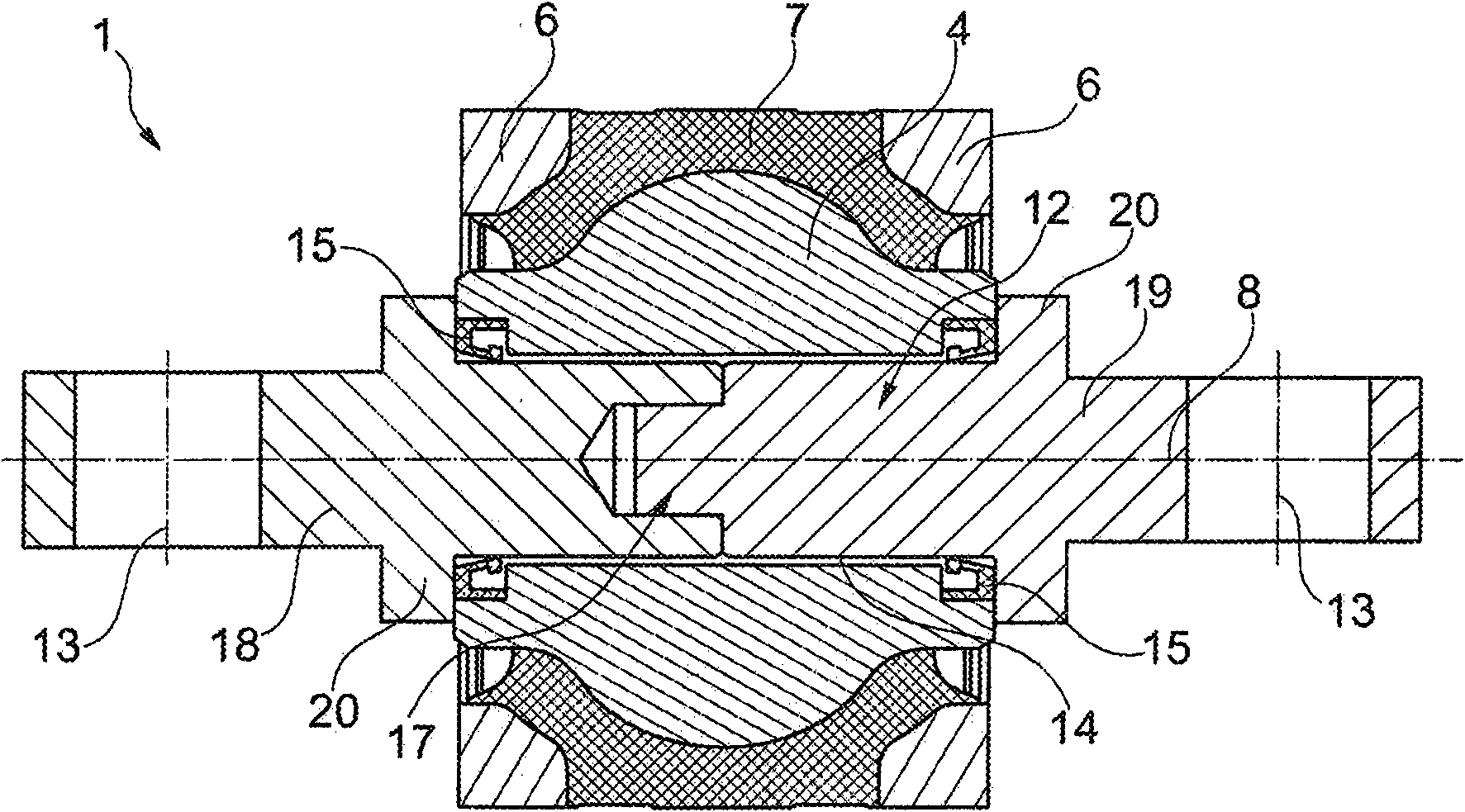

[0034] figure 1 The cross-section of a vehicle 10 (for example a truck or off-road vehicle) shown in , comprises two swing arms 2 , 3 which form an acute angle in a triangular suspension arm arrangement and extend in a V-shape relative to one another in plan view. At the apex of the triangle formed in this way, the swing arm is engaged with the axle 11 (here the rear axle) by means of the articulation 1 . The axle is enlarged in a central region with respect to the transverse direction from the vehicle to accommodate the differential. Thus, the articulation device 1 can be fitted at the upper end of said area 9 of the rear axle 11 enlarged to accommodate the differential, thereby constituting a transverse guide and a longitudinal guide for the axle 11 . The two pivoting arms 2 , 3 for support here can be connected in their upper regions 2 a , 3 a to, for example, longitudinal frame parts for load bearing. A similar articulation device 1 can also be used here.

[0035] Here,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com