Loaded copper catalyst for preparing anhydrous methanal by direct dehydrogenation of methanol, and preparation method for loaded copper catalyst

A technology of copper catalyst and anhydrous formaldehyde, which is applied in the field of catalysis, can solve the problems of high reaction temperature, high price, and low catalyst activity, and achieve the effects of simple preparation, low price, high activity and selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

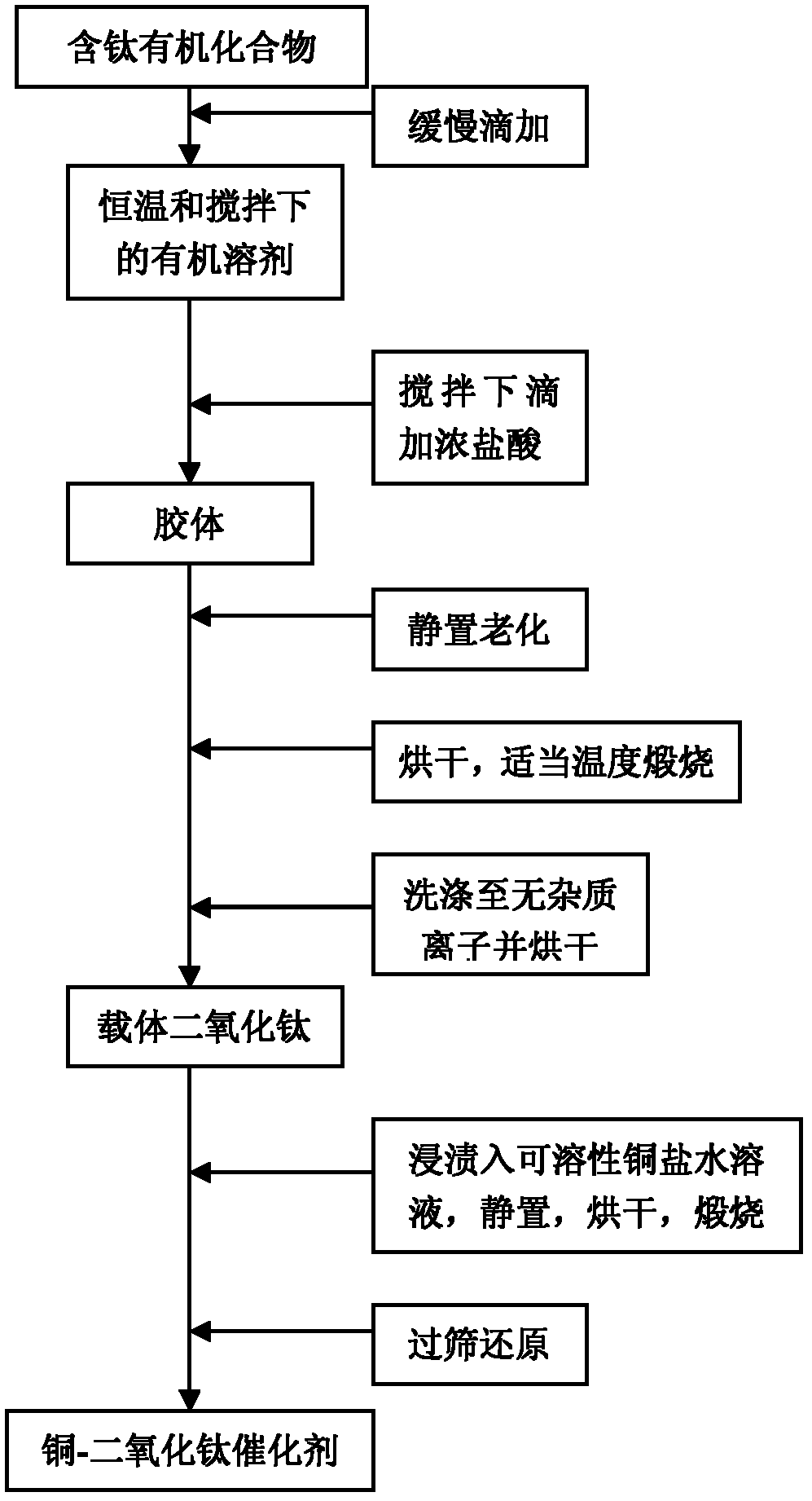

Method used

Image

Examples

Embodiment 1

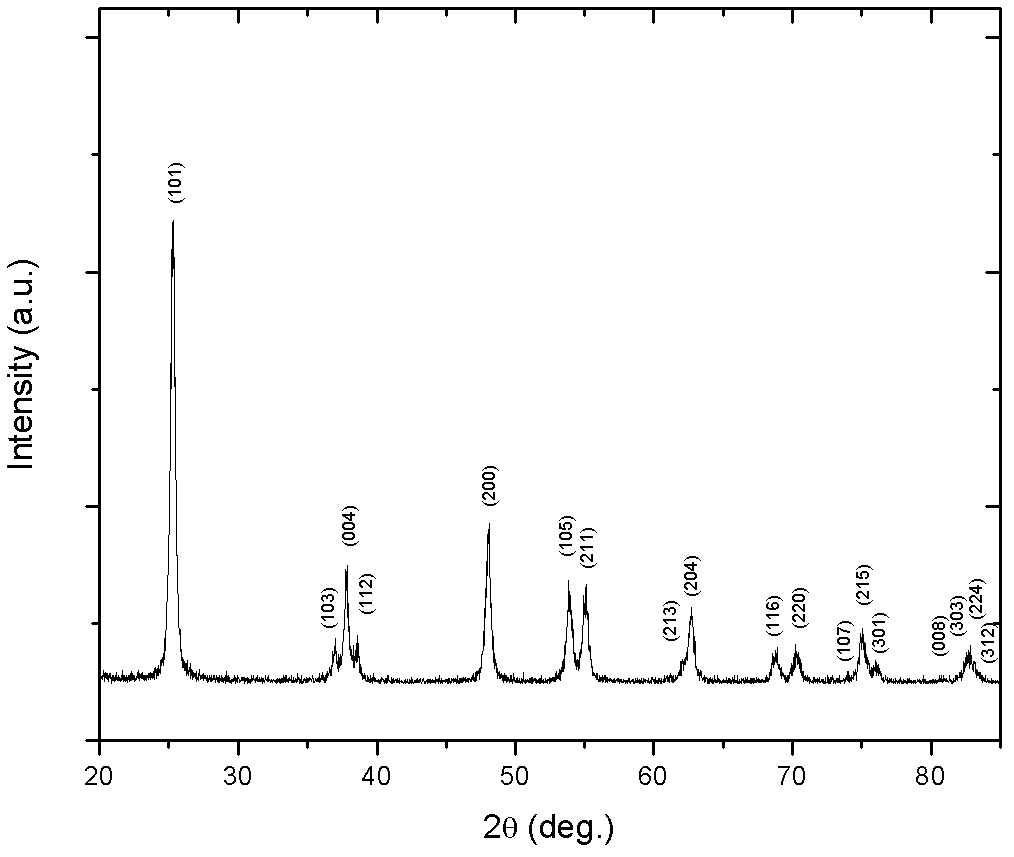

[0022] Example 1: Maintaining 60 o Under heating in a water bath and electromagnetic stirring, slowly add 10 mL of n-butyl titanate dropwise to a certain amount of absolute ethanol to form a light yellow colloid. After stirring for 30 minutes, add 2 mL of concentrated hydrochloric acid dropwise and stir evenly. Put colloid at 25 o After standing and aging for 24 hours under C, place it in an oven at 100 o C drying. Grind and dry the solid into powder, in the air atmosphere of the box furnace at 500 o C calcined for 4 hours. Wash the calcined powder with deionized water to be free of chloride ion (silver nitrate solution test), 80 o Dry the obtained carrier titanium dioxide in an oven. The spectrum of X-ray diffraction analysis of the carrier is as follows figure 2 , indicating that its crystal phase is anatase titanium dioxide. According to the content of the copper component, the prepared titanium dioxide was immersed in a 0.5mol / L copper acetate aqueous solution, and...

Embodiment 2

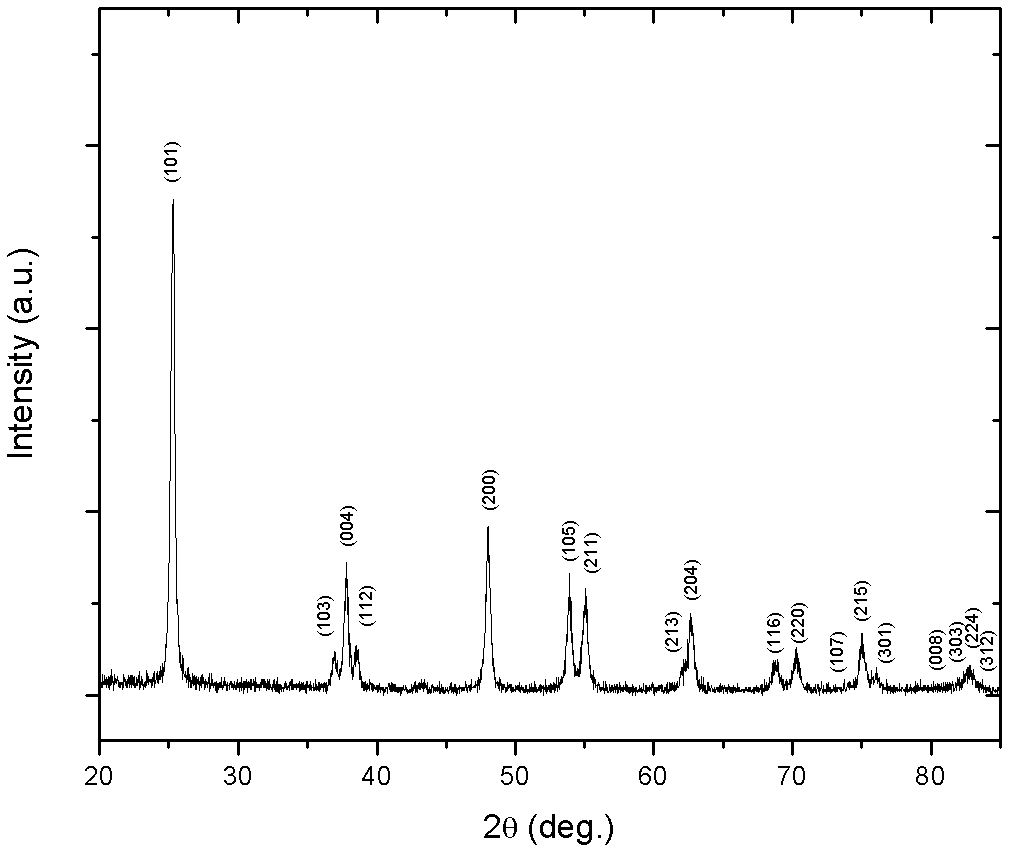

[0023] Example 2: Maintaining 70 o Under heating in a water bath and electromagnetic stirring, slowly add 15 mL of tetraethyl titanate dropwise to a certain amount of anhydrous acetone to form a light yellow colloid. After stirring for 60 minutes, add 1 mL of concentrated hydrochloric acid dropwise and stir evenly. Colloid at 60 o After standing and aging for 20 hours under C, put it in an oven for 90 o C drying. Grind and dry the solid into powder, in the air atmosphere of the box furnace at 450 o C calcined for 5 hours. Wash the calcined powder with deionized water to be free of chloride ion (silver nitrate solution test), 90 o Dry the obtained carrier titanium dioxide in an oven. The X-ray diffraction analysis of the carrier shows that its crystal phase is anatase titanium dioxide. According to the content of the copper component, the prepared titanium dioxide was immersed in a 1 mol / L copper acetate aqueous solution and left to stand for 20 hours. 90 o After dryin...

Embodiment 3

[0024] Example 3: In Sustain 6 o C water bath heating and electromagnetic stirring, slowly dropwise add 15mL tetraethyl titanate to a certain amount of anhydrous acetone to form a light yellow colloid, stir for 60 minutes, then add dropwise 2L concentrated hydrochloric acid and stir evenly. Colloid at 60 o After standing and aging for 20 hours under C, put it in an oven for 90 o C drying. Grind and dry the solid into powder, in the air atmosphere of the box furnace at 400 o C calcined for 5 hours. Wash the calcined powder with deionized water to be free of chloride ion (silver nitrate solution test), 90 oDry the obtained carrier titanium dioxide in an oven. The X-ray diffraction analysis of the carrier shows that its crystal phase is anatase titanium dioxide. According to the content of the copper component, the prepared titanium dioxide was immersed in a 1 mol / L copper acetate aqueous solution and left to stand for 20 hours. 90 o After drying in the oven, put it in t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap