Gravity grading and stoning machine for grains

A technology of gravity classification and stone removal machine, which is applied in the direction of solid separation, separation of solids from solids by air flow, and filtration and sieving. It can solve problems such as difficult operation, high proportion of light wheat, and poor classification quality. To achieve the effect of improving the effect of grading and stone removal, uniform distribution and quality improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

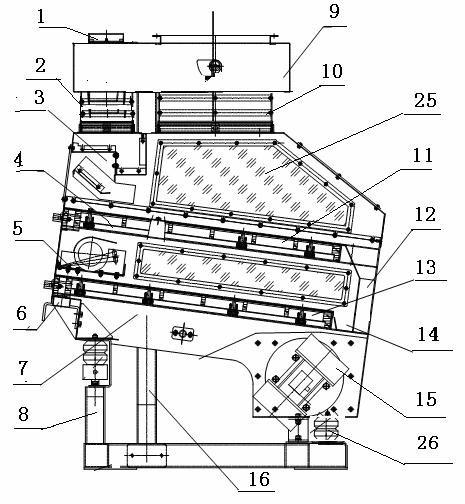

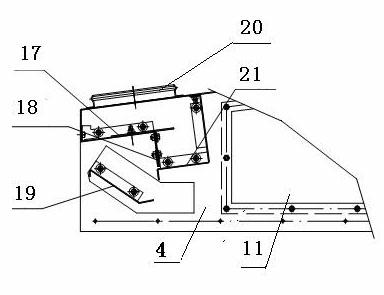

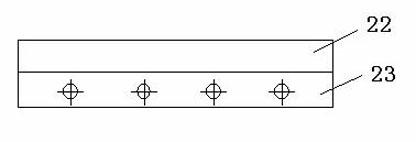

[0016] Grain Gravity Classification Destoner of the present invention such as figure 1 Shown, comprise sieve body 7, suction device 9, feeding device 3, two vibrating motors 15, discharge port, front vibrating bearing 26 and rear vibrating bearing 8. The sieve body is connected with the suction device through the suction pipe 10, and the suction device is connected with the vacuum system, and the suction pipe and the feed pipe are all made of rubber hoses. The inlet 20 of the feeding device is connected to the feed port 1 through the feed pipe 2, and the feed port is connected to the grain material conveying equipment through a pipeline. The discharge port includes a light material outlet 12, a heavy material outlet 14 and a stone discharge port 6. The sieve body 7 is provided with an upper sieve surface and a lower sieve surface. The upper sieve surface is composed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com