Cold-rolled strip steel flattening device and cold-rolled strip steel cross break eliminating method

A technology of cold-rolled strip steel and horizontal folding, applied in metal rolling, metal rolling, manufacturing tools, etc., can solve problems such as high occurrence rate, achieve high elimination rate, and eliminate quality defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The cross-fold defect shown by the tempering unit is not fully exposed after the annealing process. It appears between the uncoiler and the frame after the temper machine is uncoiled. Reduced, but not completely eliminated. Therefore, the analysis defects mainly occur between these two control points, the uncoiling steering roller and the tension roller.

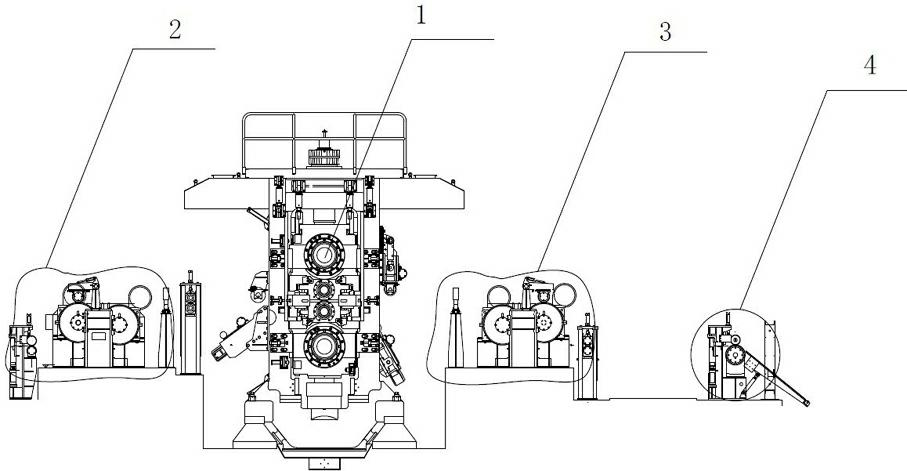

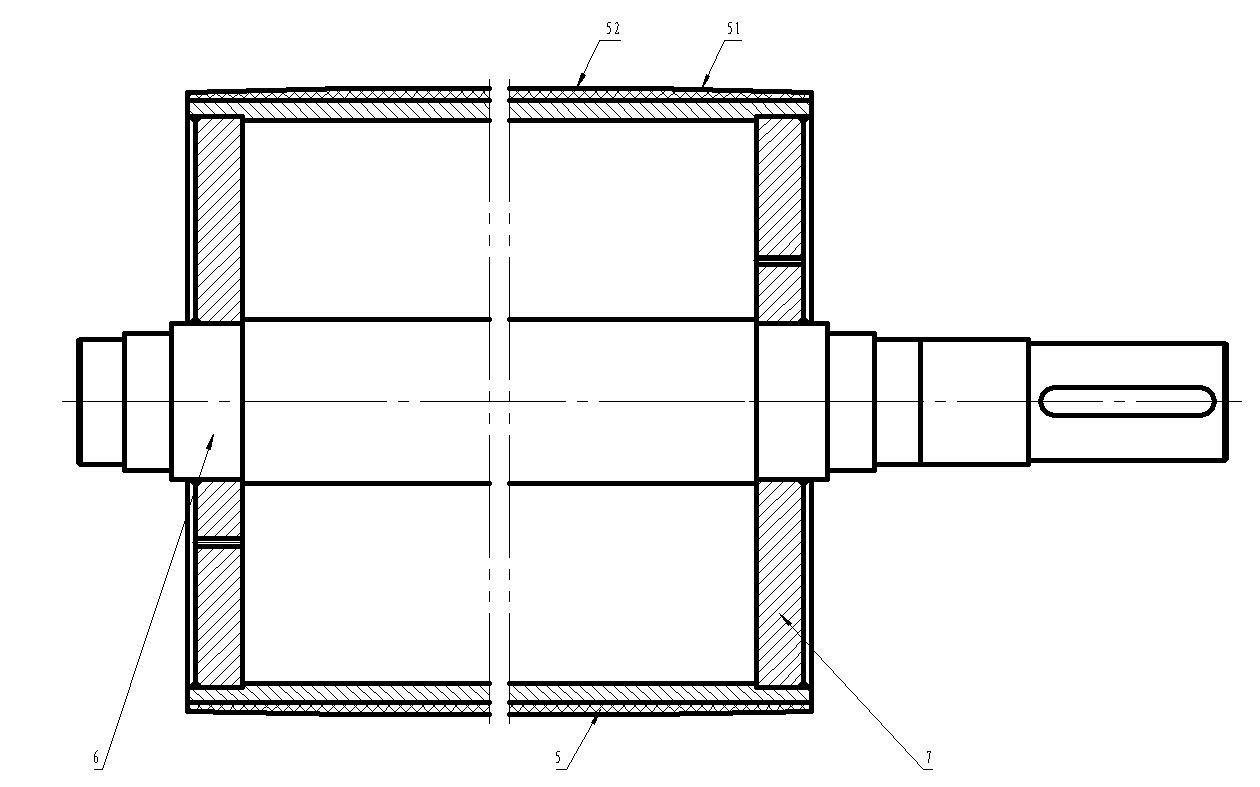

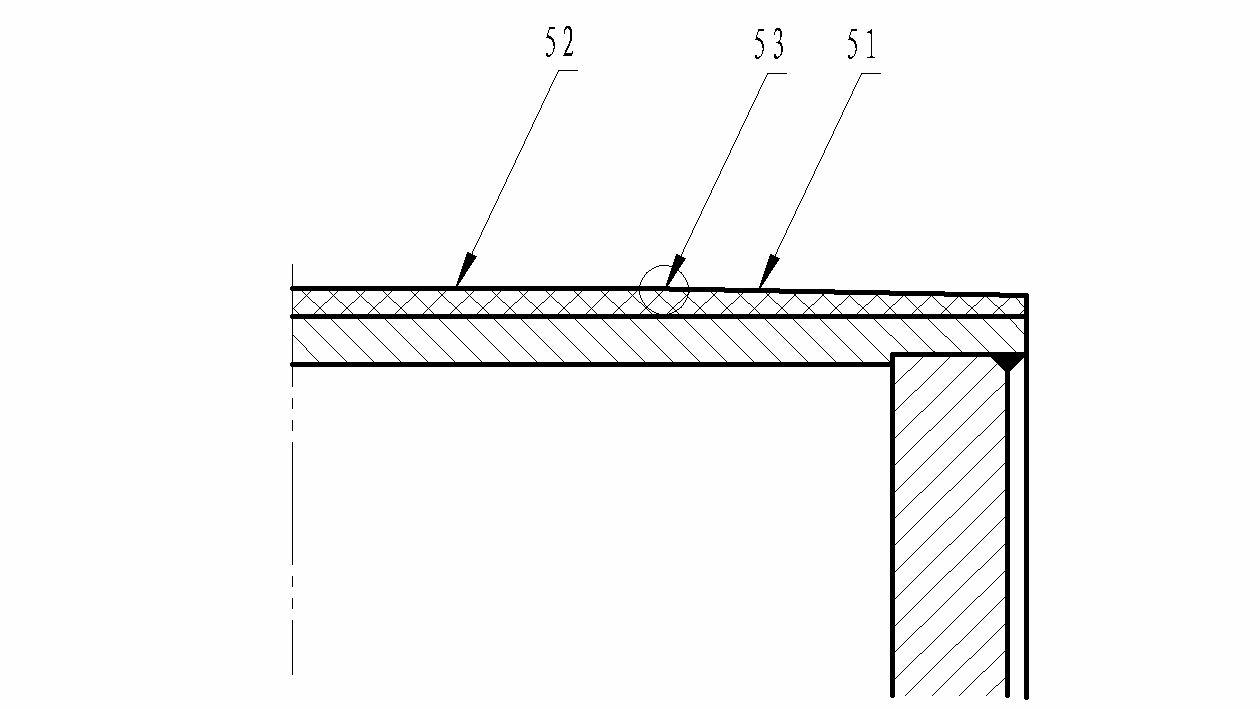

[0018] The structure of a kind of cold-rolled strip leveling device embodiment is as figure 1 As shown, an uncoiling tension roller 2 and 3 are respectively arranged at the front and back of the machine of the device tempering machine 1, and an uncoiling steering roller 4 is also provided before the tension roller 3 in front of the machine along the strip advancing direction, as figure 2 As shown, the middle section of the two uncoiling tension rollers and the uncoiling turning roller body 5 is a cylindrical structure 52, and its two ends are respectively provided with a symmetrical inclined cone structure 52, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com