New steel tube positioning method used in steel tube conveying of tack welder and realization device

A technology of steel pipe transportation and positioning method, which is applied in the direction of auxiliary equipment, welding equipment, auxiliary welding equipment, etc., which can solve the problems of high action point, increase of propeller tipping moment, large propeller height and size, etc., and achieve small force , Small structure size and small tipping moment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention and its beneficial effects will be further described in detail below in conjunction with the accompanying drawings.

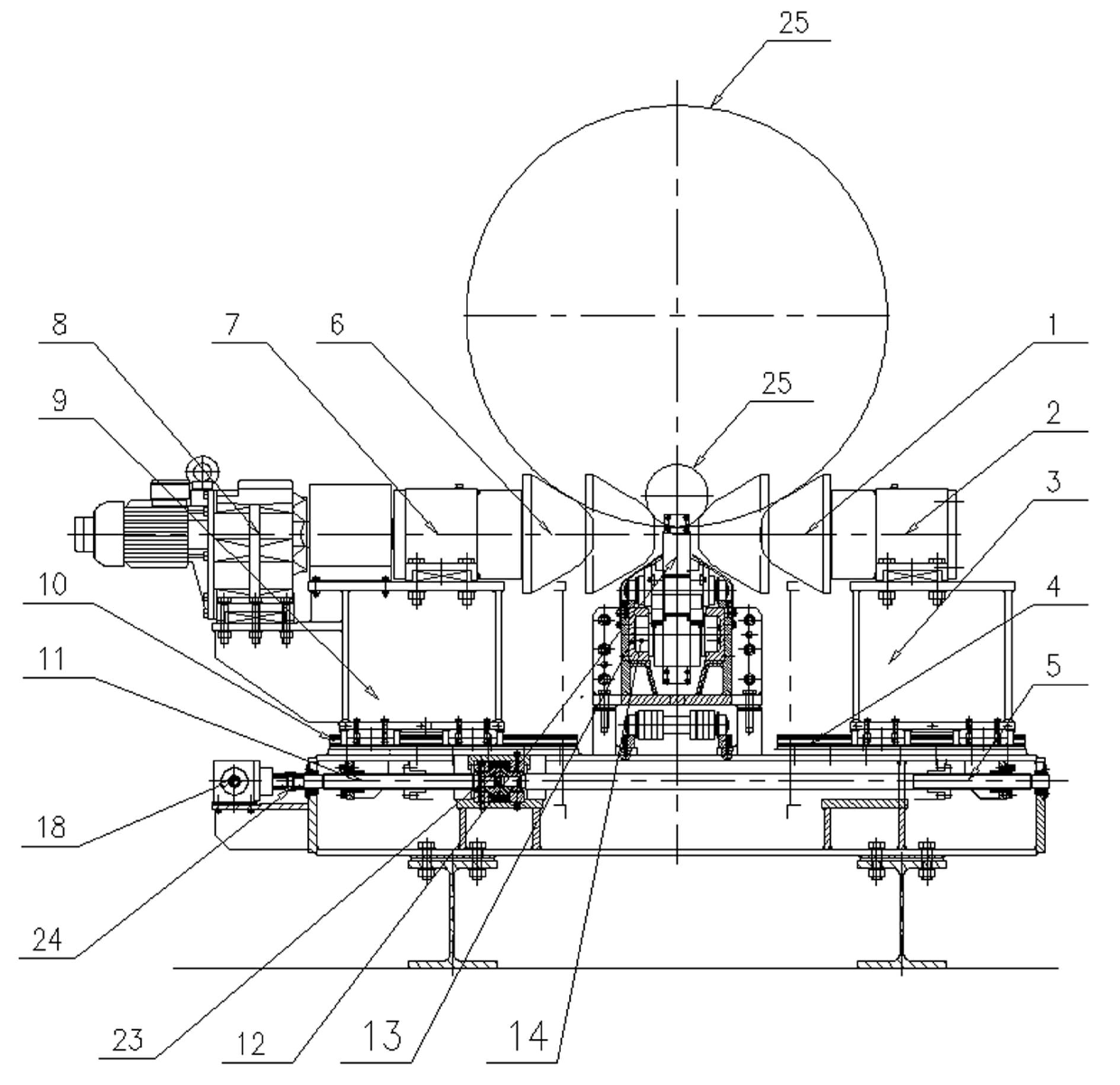

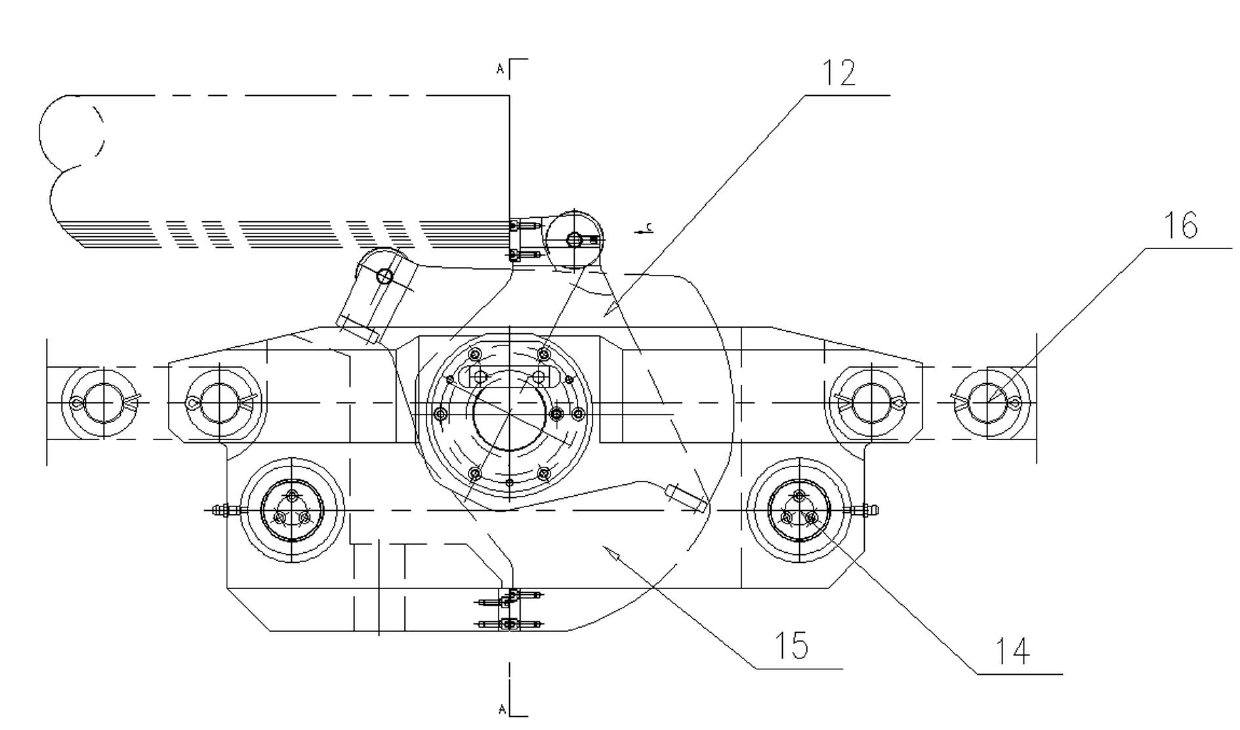

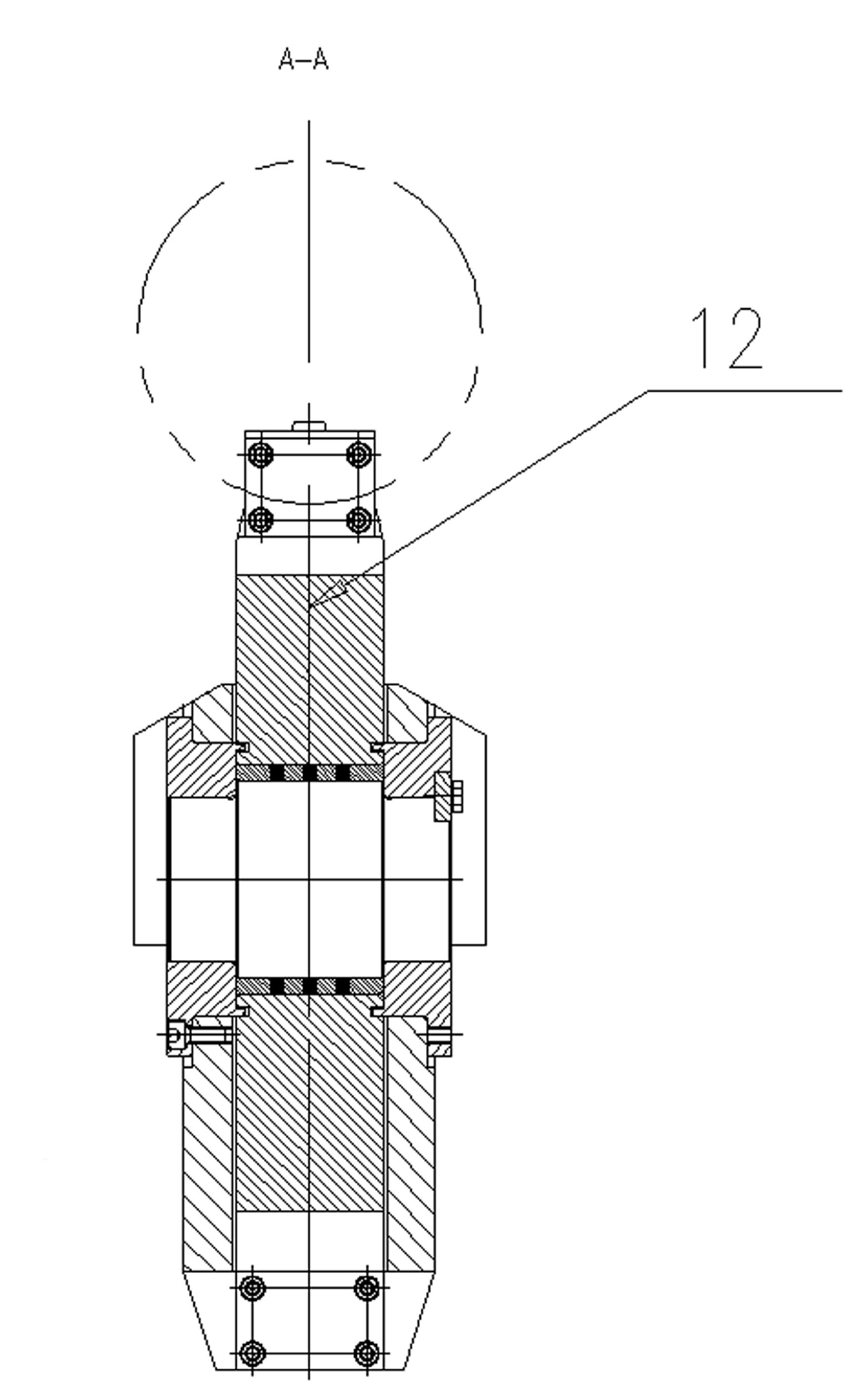

[0020] refer to Figure 1 to Figure 6 , a new positioning method for steel pipes when the steel pipes of the pre-welding machine are transported. When the steel pipes are sent to the steel pipe seaming machine, they are positioned at the same height as the lower bus bar of the steel pipes. The method is realized by the following embodiments.

[0021] A device for realizing a new positioning method for steel pipes when the steel pipes of the pre-welding machine are conveyed, including a steel pipe seaming machine, a steel pipe propulsion device arranged on the center line of the steel pipe seaming machine, and the left and right half conveying rollers of the steel pipes 25 of the pre-welding machine The road is arranged on the side of the center line of the steel pipe seaming machine, and the left and right half conveying rollers 6, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com