Dolly steel rope driven crane with C-slot cantilever beam and balance weight

A cantilever beam and C-shaped trough technology, which is applied in the direction of traveling bridge cranes, cranes, load blocks, etc., can solve the problems of low working level, waste of manpower and material resources, and small tonnage, so as to reduce equipment investment and facilitate operation , The effect of convenient assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

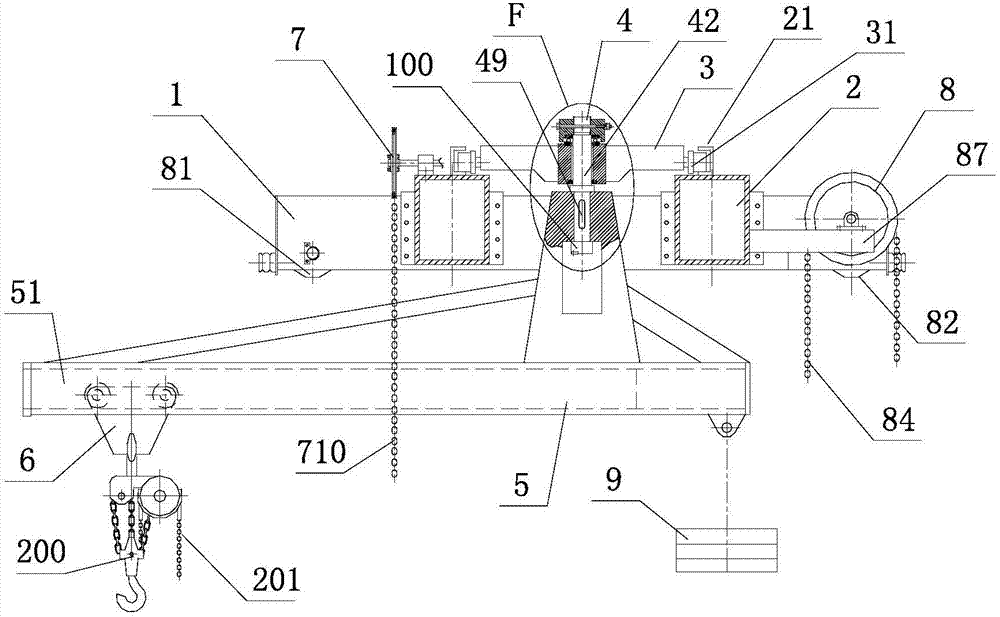

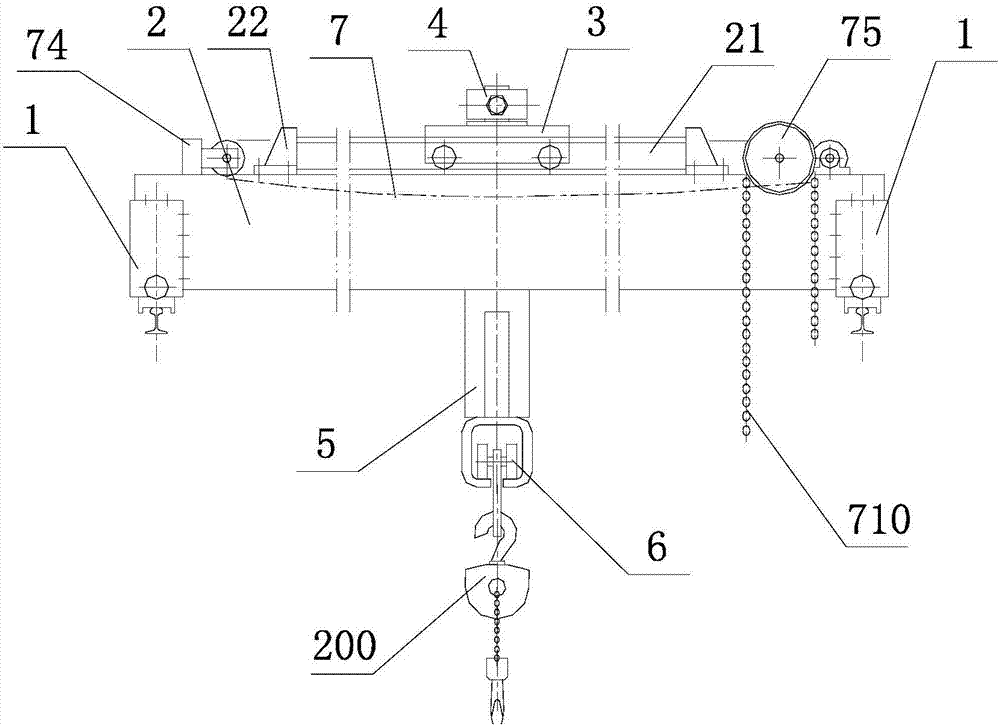

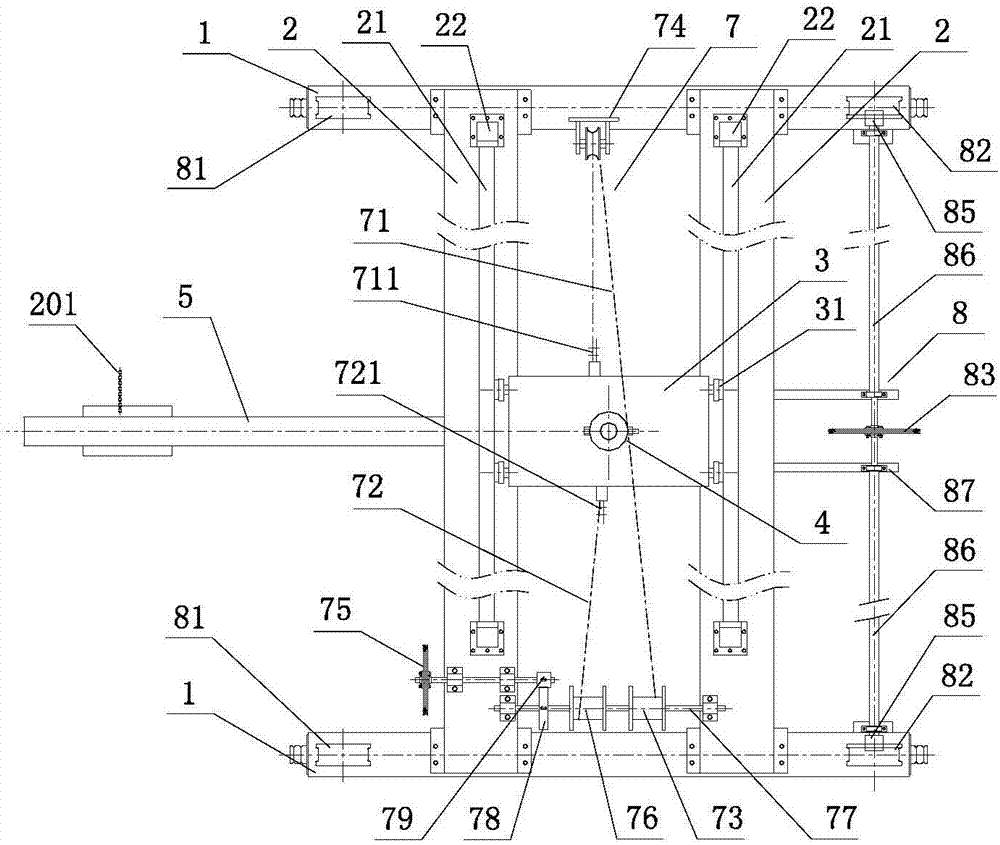

[0026] like figure 1 , figure 2 , image 3As shown, a trolley steel rope-driven crane with a C-shaped groove cantilever beam and a counterweight includes two end beams 1 and two main beams 2, which form a double-girder bridge structure; between the two end beams A trolley running device 8 is provided; an inverted "U" track 21 is provided above the two main girders 2, and the track opening faces the inner side of the main girder; The car block is connected to the main beam with bolts; a running trolley 3 is connected between the two rails 21; the wheels 31 on the running trolley run on the rails; the running trolley is equipped with a steel rope drive Device 7; the running trolley is provided with a rotating mechanism 4; the lower end of the boom shaft 42 in the rotating mechanism is connected with the cantilever member 5 through a flat key 49, and is connected and fastened by a nut 100; the cantilever on the cantilever member The beam 51 is made of C-shaped channel steel, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com