Proportioning device

A batching box and batching hopper technology, applied in the direction of selling raw material supply devices, etc., can solve the problems of potential safety hazards, affecting batching speed, low work efficiency, etc., and achieve the effect of improving driving conditions, reducing frequency of use, and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

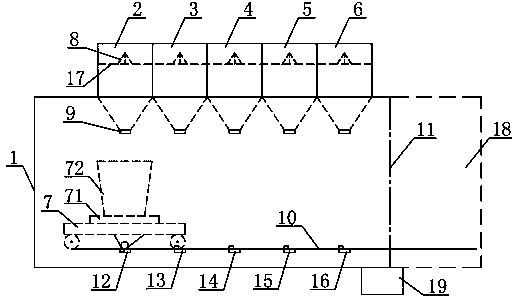

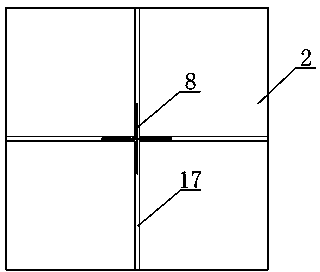

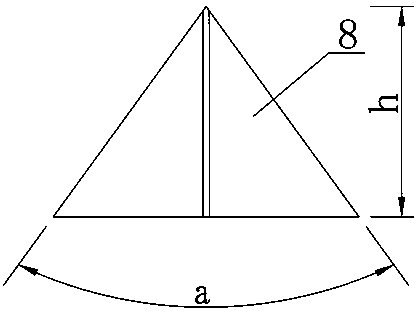

[0012] like figure 1 As shown, the batching device includes a batching box 1 closed all around, and the top of the batching box 1 is provided with five feed bins, which are respectively the first feed bin 2, the second feed bin 3, the third feed bin 4, and the fourth feed bin 5. The fifth silo 6, the bottom end of each silo extends into the batching box 1, the top of each silo is open, and a knife 8 with a sharp edge upward is arranged in the silo, such as figure 2 As shown, two cross channel steels 17 are welded in the feed bin, and the described cutting tool 8 is welded on the cross intersections of the channel steels 17, as image 3 , Figure 4 As shown, the cutter 8 is cross-shaped and pointed. In actual work, for the smoothness of blanking, the angle α formed by the cutter 8 along the cross-symmetrical blade is usually set in the range of 45° to 60°. The height h is usually set within the range of 150mm to 300mm. The bottom of each silo is provided with a pneumatic fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com