Installation method of overlong twin-skeg structure segment and shaft bracket dock

An installation method and a stern shaft frame technology, which are applied to ship components, ship construction, transportation and packaging, etc., can solve problems such as complex hull structure design and construction technology, and achieve the effects of shortening the production cycle and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and implementation examples, but the protection scope of the present invention should not be limited thereby.

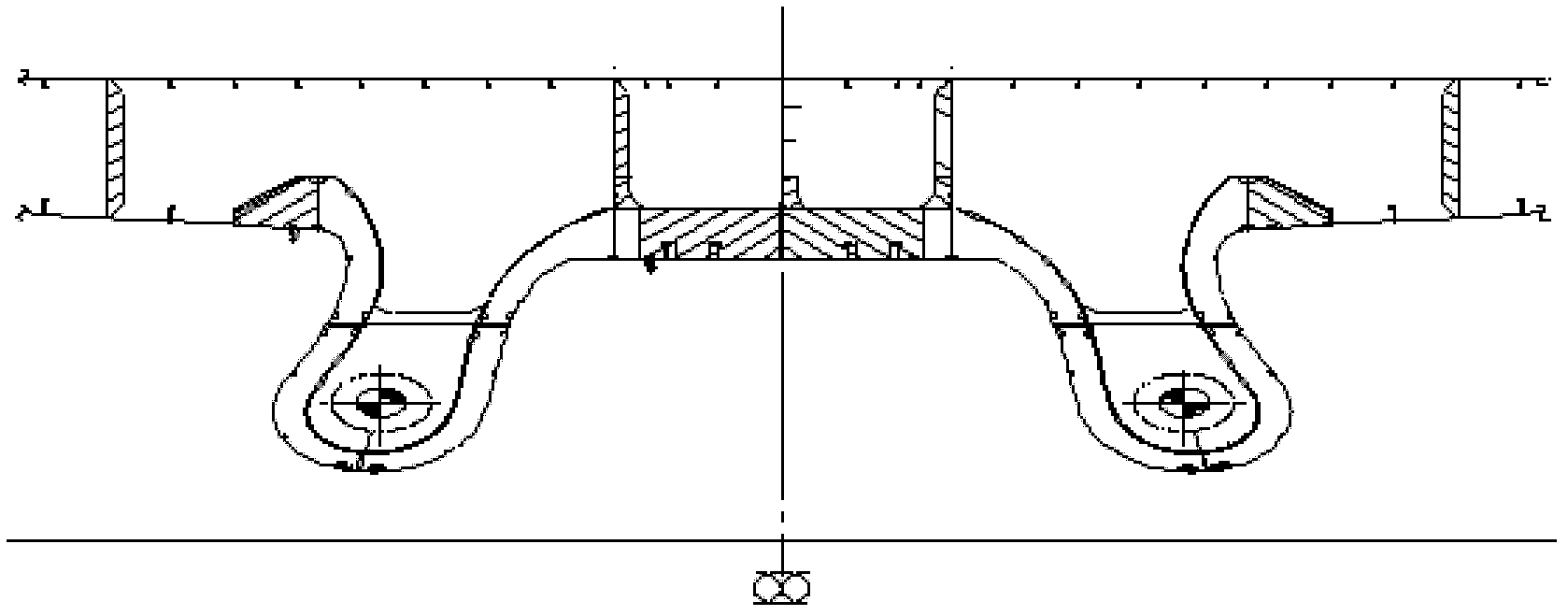

[0029] This embodiment is a large-scale special ship with super long double skeg lines. The particularity of the separation of the main engine of this ship is:

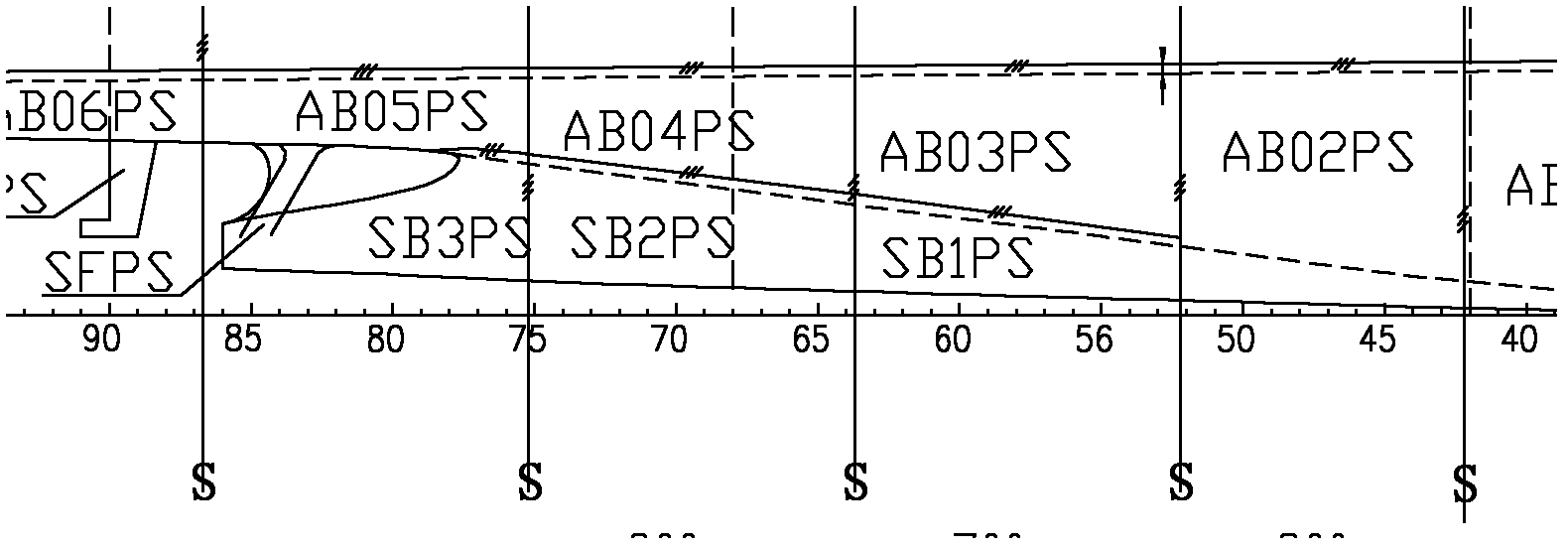

[0030] 1) The main engine is set at the left, right, front and back positions, the length of the left and right stern axes is different from the positioning angle, and the length difference between the two axes is nearly 20 meters;

[0031] 2) The main shaft system is all wrapped inside the linear structure of the hull skeg. There are stern tubes in the left and right skeg structures, and there are front bearings, middle bearings and bearing bases inside. The stern ends are two large V-shaped cast steel bracket, also referred to as the stern shaft frame SFPS;

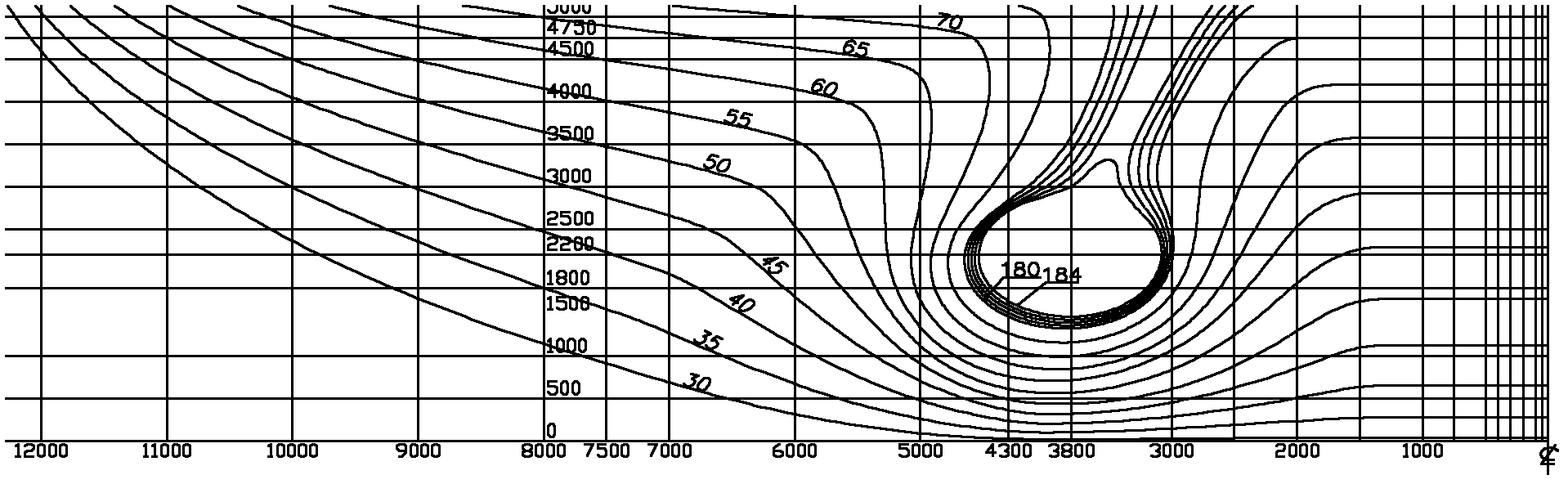

[0032] 3) The fin-shaped curvature line o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com