Tank roof fence device of tank truck

A fence and tank car technology, applied in the field of tank cars, can solve problems such as complicated welding process, increased production costs, and wear of tank car tires

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

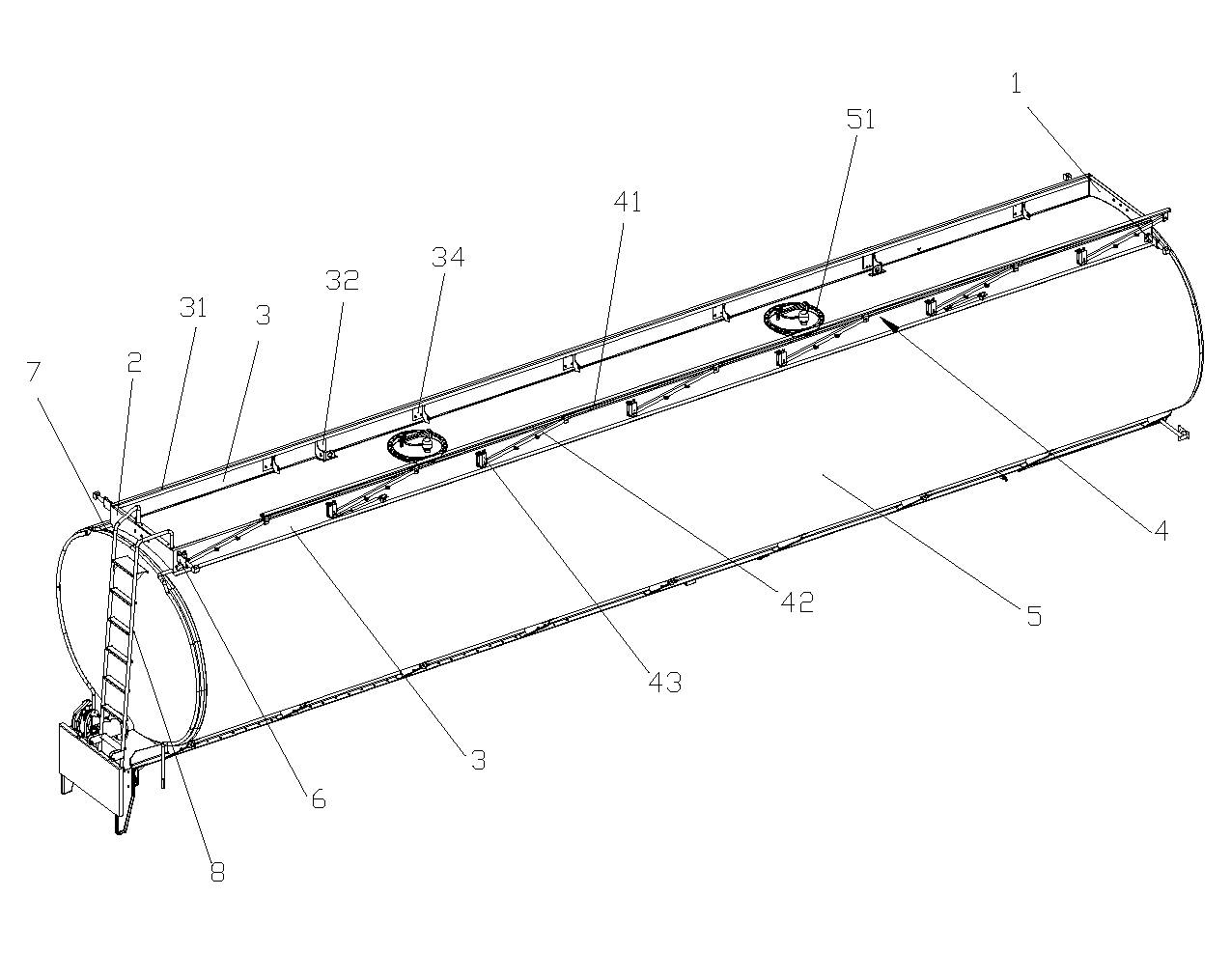

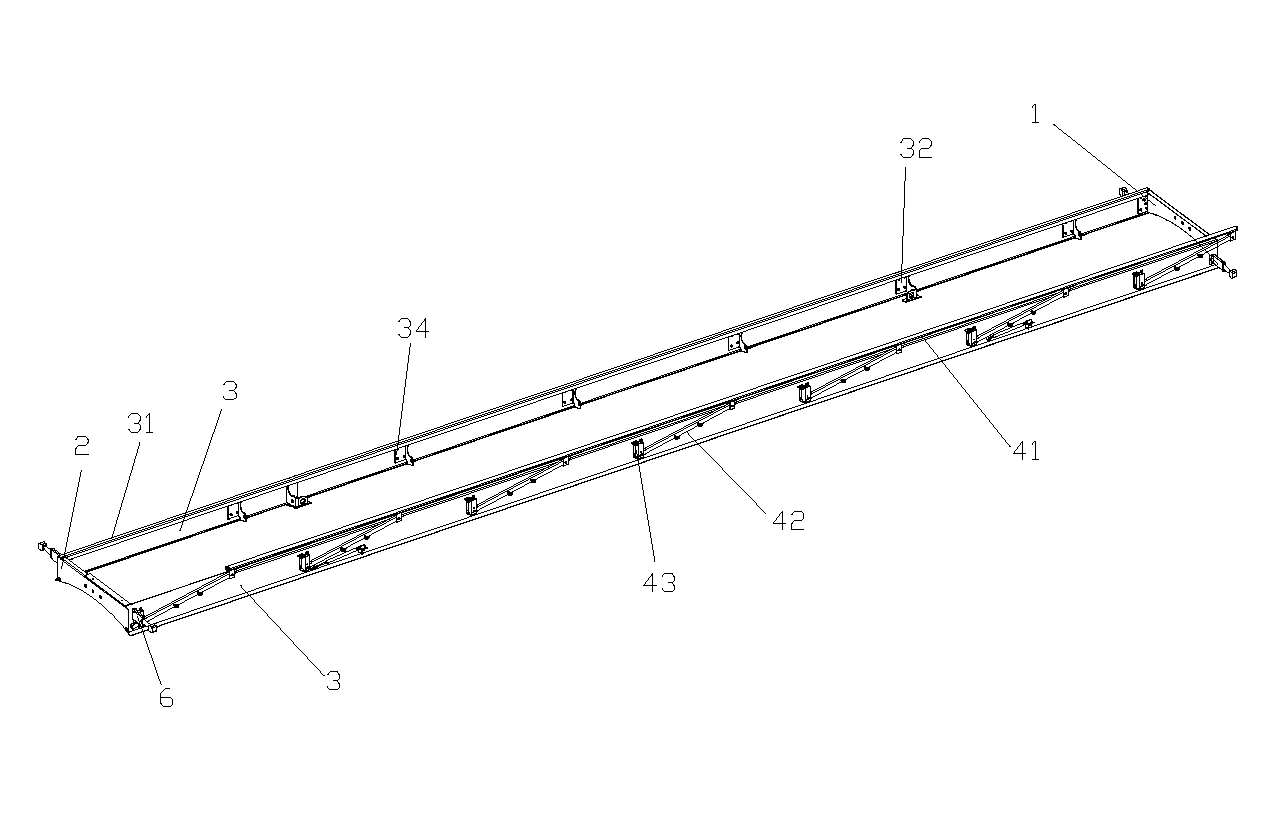

[0039] Embodiment 1 of a tank roof fence device for a tank car of the present invention is as follows: Figure 1 to Figure 7 As shown, it includes a fence arranged on the top of the tank, and the fence includes a front wall 1, a rear wall 2, and side wall panels 3 respectively arranged on both sides of the front wall 1 and the rear wall 2, wherein the front wall 1. The bottom of the back panel 2 is welded to the tank roof, the bottom of the side panel 3 is bonded to the tank roof, and the inner side of the side panel 3 is provided with a fence support 34 and a tank lug 32, and the fence support 34 and the tank The body lugs 32 are all welded to the tank top. Since the side wall 3 is bonded to the tank roof by gluing process, compared with the welding method in the prior art, the gluing process is simpler and faster, and the production efficiency is high.

[0040] In this embodiment, the side panel 3 is integrally formed by engineering plastics or aluminum alloy profiles. This...

Embodiment 2

[0045] A tank roof fence device for a tank car in this embodiment can be found in Figure 1 to Figure 6 , on the basis of Embodiment 1, the features not explained in this embodiment adopt the explanations in Embodiment 1, and will not be repeated here. The difference between this embodiment and embodiment 1 is:

[0046] There are at least two fence supports 34 and tank lugs 32 .

[0047] The side panel 3 is fixedly connected to the fence support 34 and the tank lug 32 respectively by bolts.

[0048] In addition to fastening the side wall plate 3 by bolts, the side wall plate 3 may be bonded and fixed to the fence support 34 and the tank lug 32 respectively by means of bonding.

[0049] Further, in order to strengthen the firmness of the connection of the side wall 3, the side wall 3 can also be fixed by means of bolt fastening and bonding, that is, the fence support 34, the tank lug 32 and the side wall 3 Bonding and then fastening with bolts to strengthen the connection fi...

Embodiment 3

[0060] A tank roof fence device for a tank car in this embodiment can be found in figure 1 , figure 2 and Figure 7 , on the basis of Embodiment 1, the features not explained in this embodiment adopt the explanations in Embodiment 1, and will not be repeated here. The difference between this embodiment and embodiment 1 is:

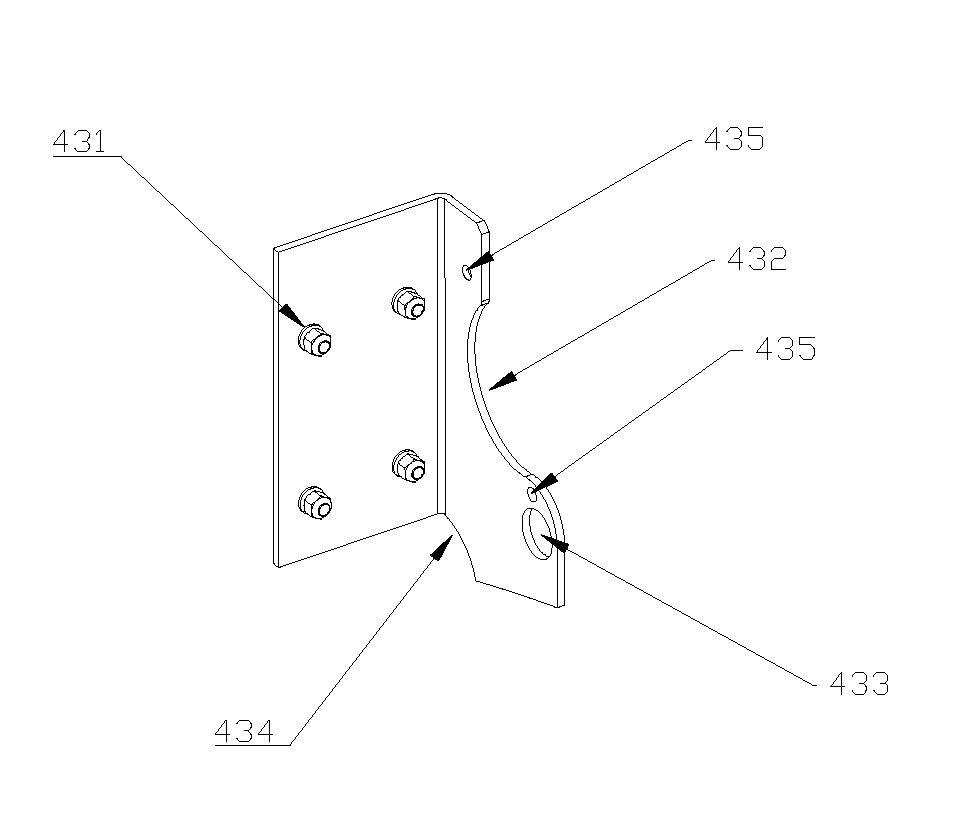

[0061] In the present embodiment, the guardrail mechanism 4 includes a guardrail support bar 41, a rotating rod 42 and a guardrail support 43, one end of the rotating rod 42 is connected with the guardrail support bar 41, and the other end of the rotating rod 42 is hinged to the guardrail support 43, and the guardrail The bearing 43 is fastened to the outside of the side panel 3, and the rotating rod 42 enables the guardrail handrail 41 to swing up and down, which is convenient for the staff to operate on the tank top and protects its safety.

[0062] At least two guardrail supports 43 are provided, and the guardrail supports 43 are fixedly connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com