Folding roller of folding machine used for folding continuous sheets

A continuous sheet and folding machine technology, applied in the field of mechanical processing, can solve the problems of increasing manufacturing cost and difficulty in operation and debugging, restricting the folding speed of folding rollers, affecting production and processing efficiency, etc. Operation to ensure the effect of neatness and consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

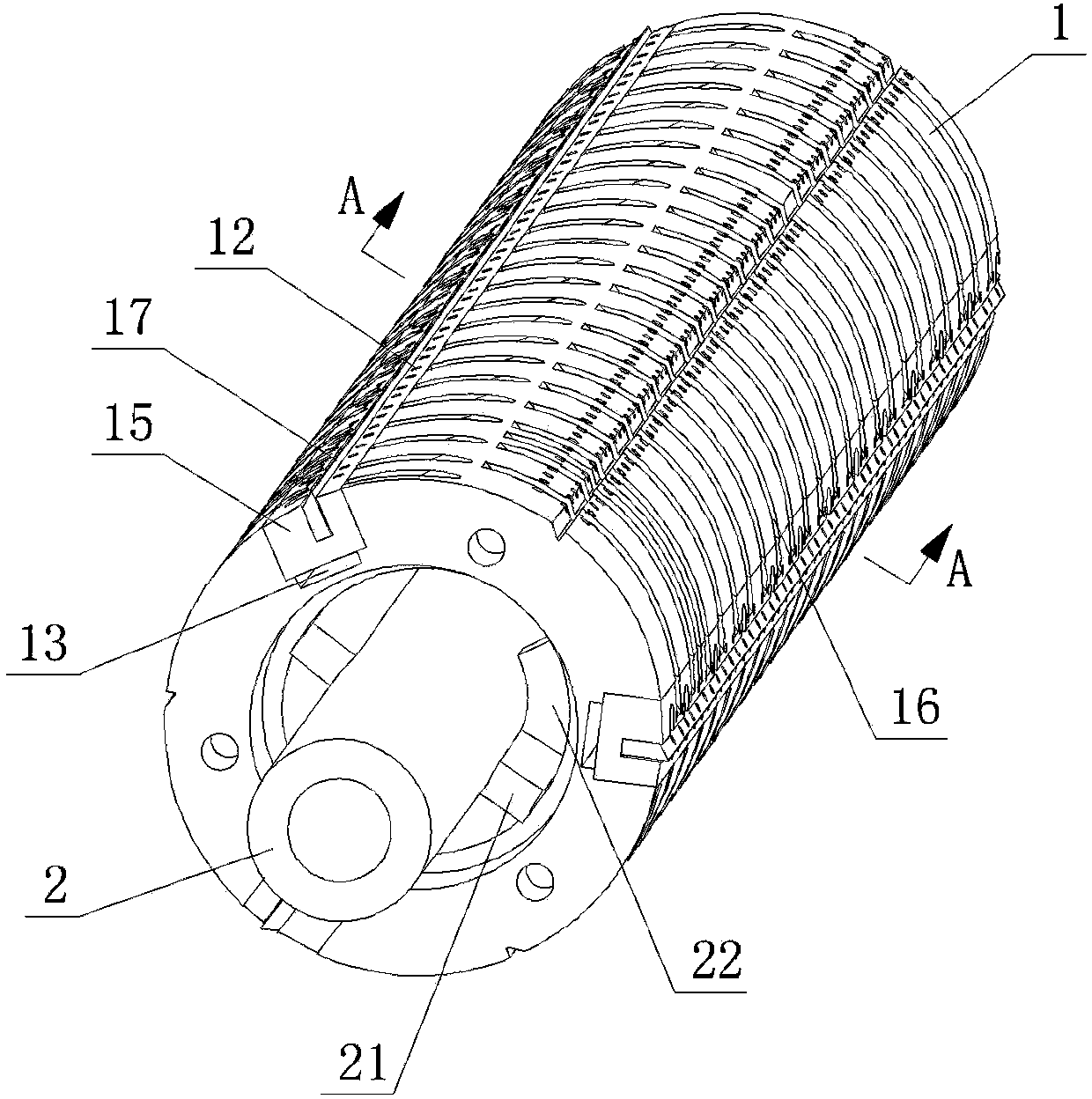

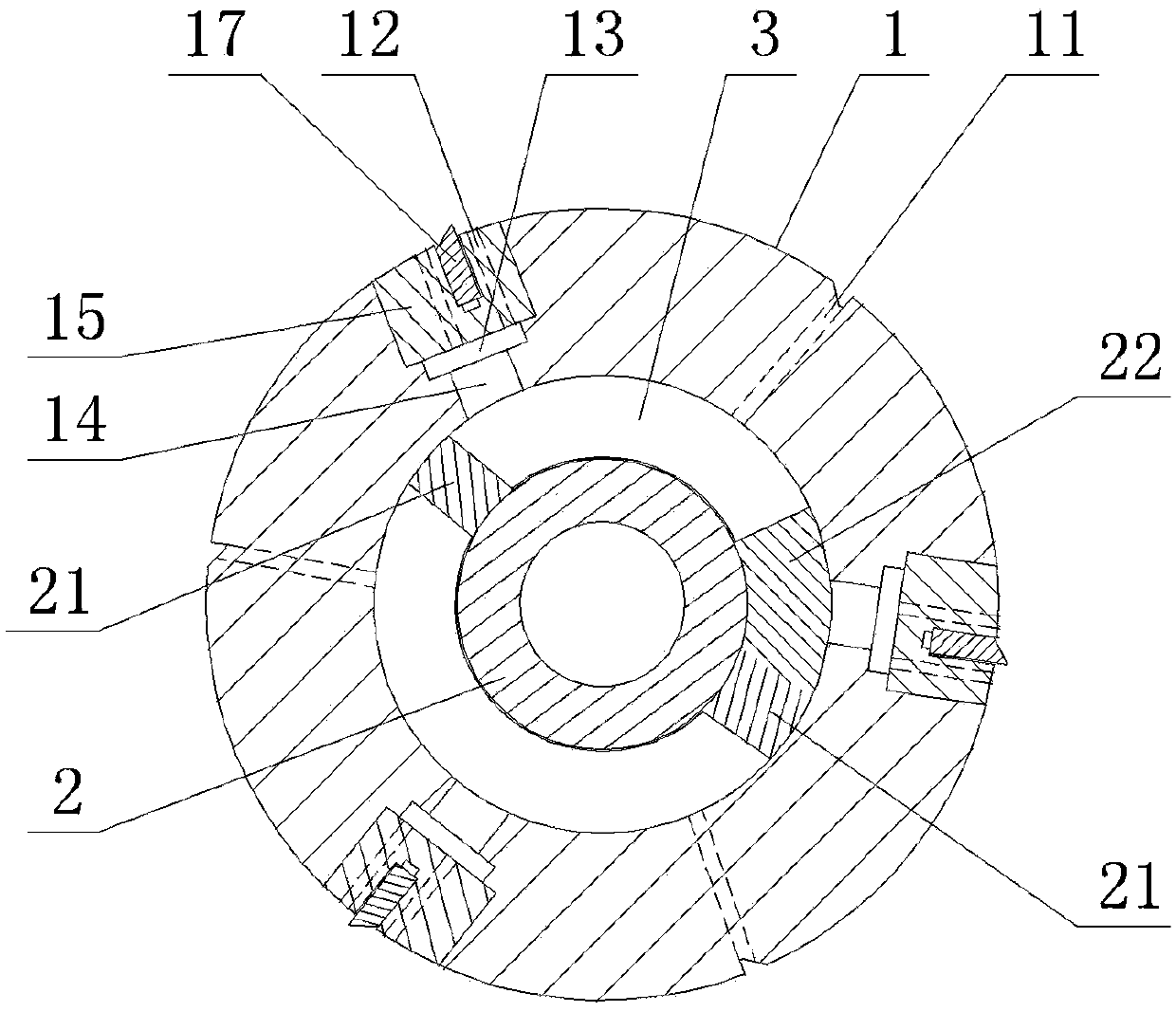

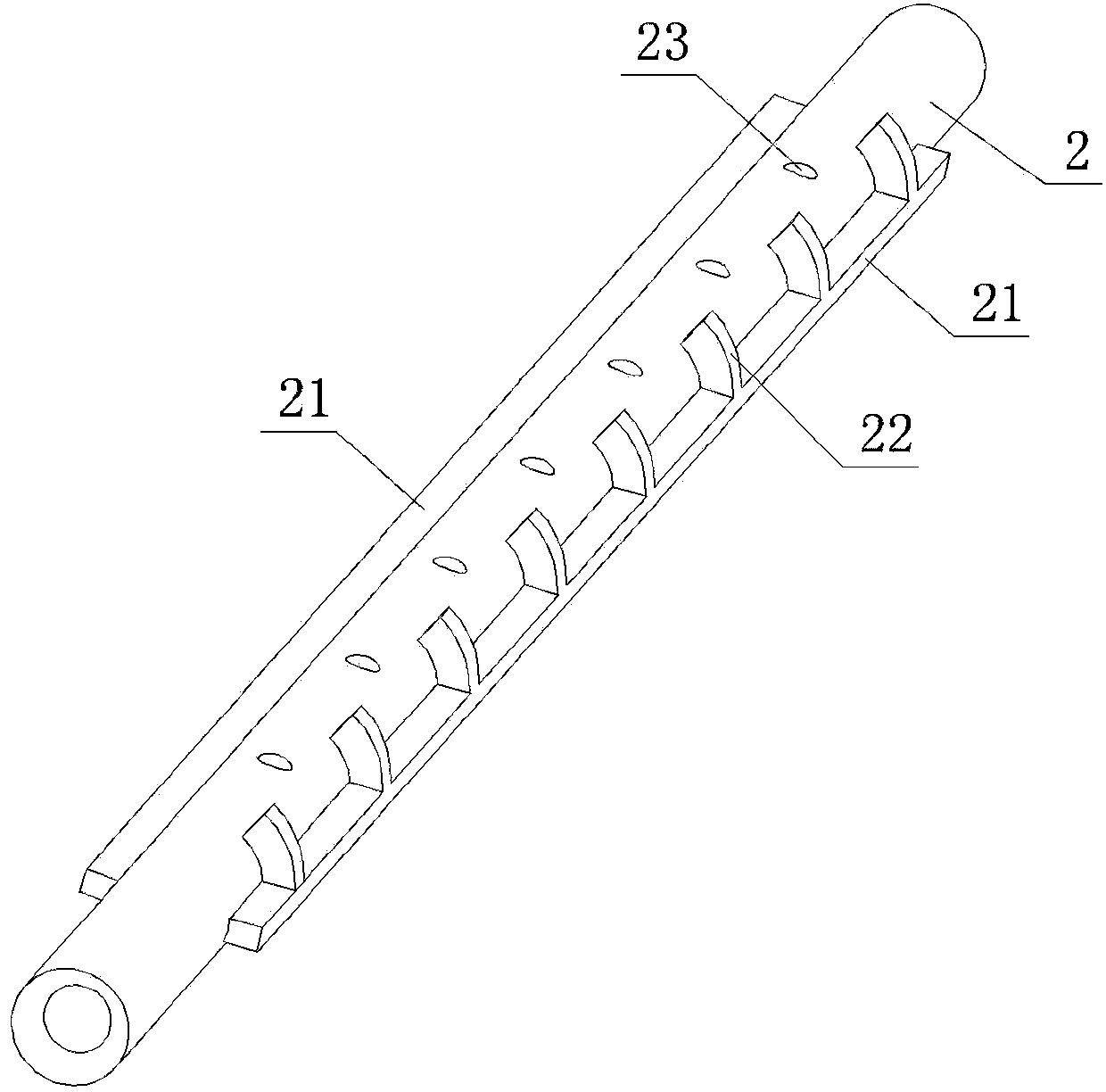

[0018] Such as Figure 1-Figure 5 As shown, the folding roller for a folding machine used for folding continuous sheets according to the present invention includes a fixed mandrel 2 and a roller body that is sleeved on the mandrel 2 and can rotate around the mandrel 2 1. The roller body 1 is a tubular body with a hollow cavity. At this time, the roller body 1 can be rotatably sealed on the mandrel 2 through bearings at both ends, or the roller body 1 can be rotatably sealed by other means. It is rotatably installed on the mandrel 2, and its two ends are sealed and connected with the mandrel 2 through structures such as sealing rings. The folding suction hole 11 and the paper feeding suction hole 12 communicated with the inner cavity of the roller body 1, and the mandrel 2 is provided with two separating ribs 21 that can divide the inner cavity of the roller body 1 into two small cavities , thereby forming a sealed cavity 3 surrounded by the upper surface of the mandrel 2, two...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com