Rough yarn-series suspended spindle capable of automatically keeping yarn leading tension constant

A hanging spindle and automatic technology, which is applied in the field of cotton spinning, can solve the problems of increasing the operator's operating strength, the yarn sliver is easy to fall, and has a hard end, and achieves the effects of easy promotion, less cost increase and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

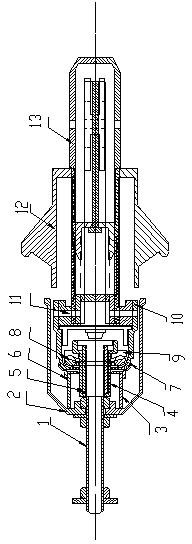

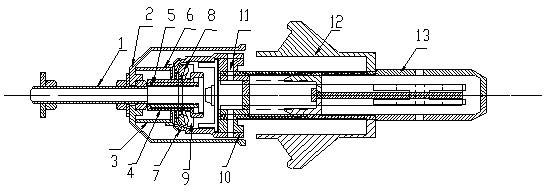

[0023] This embodiment is applicable to the situation of low yarn drawing tension. Hanging spindle screw 1 is fixed with the spinning frame by the nut at the upper end, and the hanging spindle screw is fixed with the hanging spindle cap 2 through the nut in the middle of the screw, and the weight spring jacket 4 is installed at the end of the hanging spindle screw, and the weight is installed between the weight spring jacket and the hanging spindle screw. Spring 5, the steel ball cage 9 is set on the shoulder of the weight spring jacket, a plurality of steel balls 8 are installed on the steel ball cage, the steel ball bowl 7 is set above the steel ball cage, and the steel ball bowl is set above the steel ball bowl to slide with it The contacting damping cover 6 is set with a damping spring 3 between the outside of the top of the damping cover and the inside of the top of the hanging cap, and the inner sleeve 10 of the hanging spindle at the lower end of the steel ball bowl is f...

Embodiment 2

[0028] This embodiment is applicable to the situation of yarn drawing tension wool spinning of all spinning raw materials. On the basis of applying the technical solution of Example 1, the following structure is added: between the top of the damping spring 3 and the hanging spindle cap, the lower card 16 is set and fixed on the hanging spindle screw, and the supporting step adjustment is set on the lower card. The support spring 17 of part 14 is set with a stepping adjustment part 14 at the support spring upper end, and a stepping insertion rod 15 is connected on the stepping adjustment part, and a stepping block 18 is set above the stepping insertion rod, and the stepping block passes through Upper card 19 is fixed with hanging spindle screw rod 1, and the stepping insert rod is inserted in the stepping groove of corresponding spinning raw material on the stepping block, and the set hanging spindle cap 2 is set on the stepping block. During operation, as long as the step adju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com