Wave dissipation structure suitable for sloping sea dikes

A slope-type, wave-dissipating technology, which is applied in the direction of jetties, embankments, breakwaters, etc., can solve the problems of difficulty in heightening and reinforcing dike tops, weakening wave-dissipating effects, etc., and achieve the effects of lowering elevation, enhancing wave-dissipating effects, and saving investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

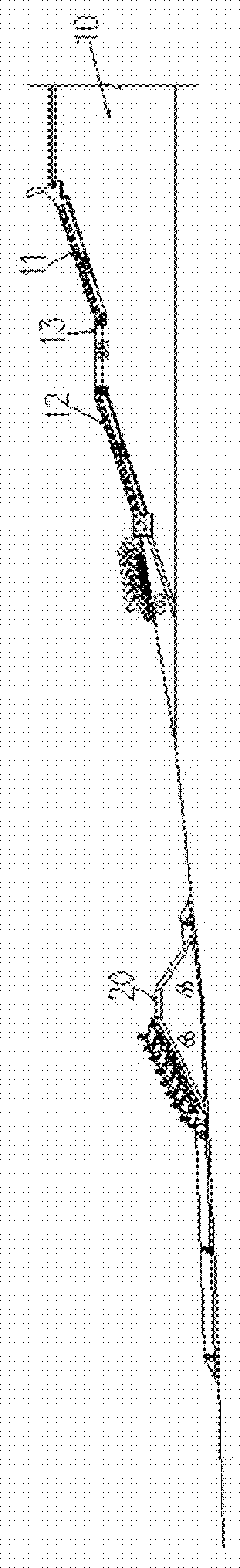

[0033] see image 3 , this type of wave dissipation structure suitable for slope-type seawalls is based on the above-mentioned existing wave dissipation structure, and an upper level wave dissipation structure 150 is provided on the fence plate revetment 131 of the upper slope 130 of the wave dissipation platform 140 . The wave-dissipating structure 150 of the upper stage is formed by stacking several wing-shaped blocks. The weight of the airfoil block is 2.0t. The airfoil-shaped wave-dissipating blocks are placed in a single-layer mosaic.

Embodiment 2

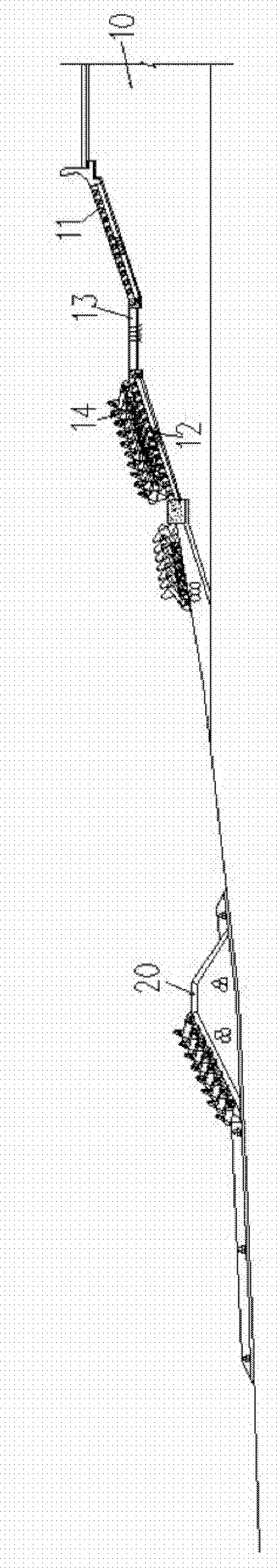

[0035] see Figure 4 , this type of wave dissipation structure suitable for slope-type seawalls is based on the above-mentioned existing wave dissipation structure, and an upper level wave dissipation structure 150 is provided on the fence plate revetment 131 of the upper slope 130 of the wave dissipation platform 140 , a next-level wave-dissipating structure 160 is provided on the fence plate revetment 121 of the next-level slope 120 of the wave-dissipating platform 140 . Both the upper-level wave-dissipating structure 150 and the lower-level wave-dissipating structure 160 are formed by stacking several wing-shaped blocks. The weight of the airfoil block is 2.0t. The airfoil-shaped wave-dissipating blocks are placed in a single-layer mosaic.

Embodiment 3

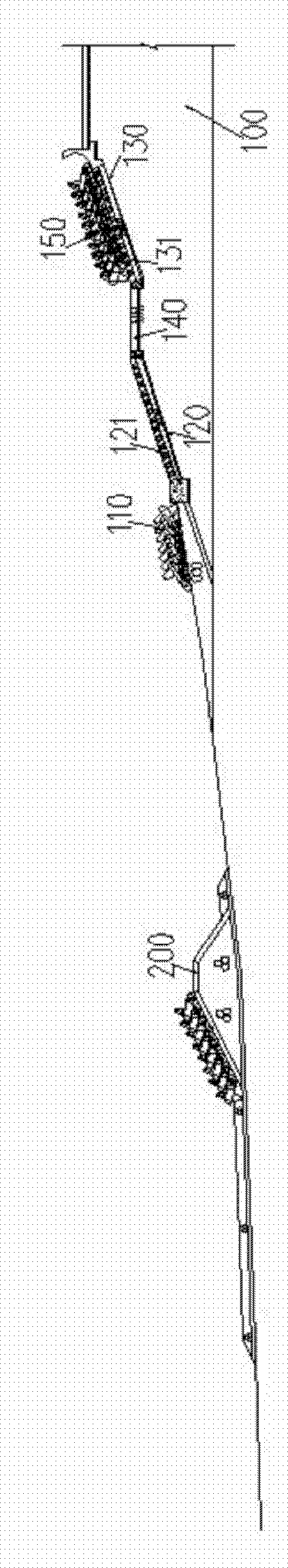

[0037] see Figure 5 , this type of wave dissipation structure suitable for slope-type seawalls is based on the above-mentioned existing wave dissipation structure, and an upper level wave dissipation structure 150 is provided on the fence plate revetment 131 of the upper slope 130 of the wave dissipation platform 140 . The wave-dissipating structure 150 of the upper stage is formed by stacking several wing-shaped blocks. The weight of the airfoil block is 2.0t. The airfoil-shaped wave-dissipating blocks are placed in a single-layer mosaic. And on the outer edge of the wave-dissipating platform 140, an intermediate wave-dissipating structure 170 is constructed by a row of spaced apart wave-dissipating piers or columns 171 . see Figure 6 and Figure 7 , the wave-dissipating pier or column 171 is cylindrical with a diameter of 0.3-0.8m, the distance between the wave-dissipating pier or column 171 is 1-3 times the diameter of the wave-dissipating pier or column 171, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com