Construction method of sand replacement mixing pile impervious wall

A construction method and a technology of mixing piles, which are applied in sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of high wall strength, low engineering cost, and high engineering cost, so as to improve the strength of the pile body and increase the adhesion , the effect of low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

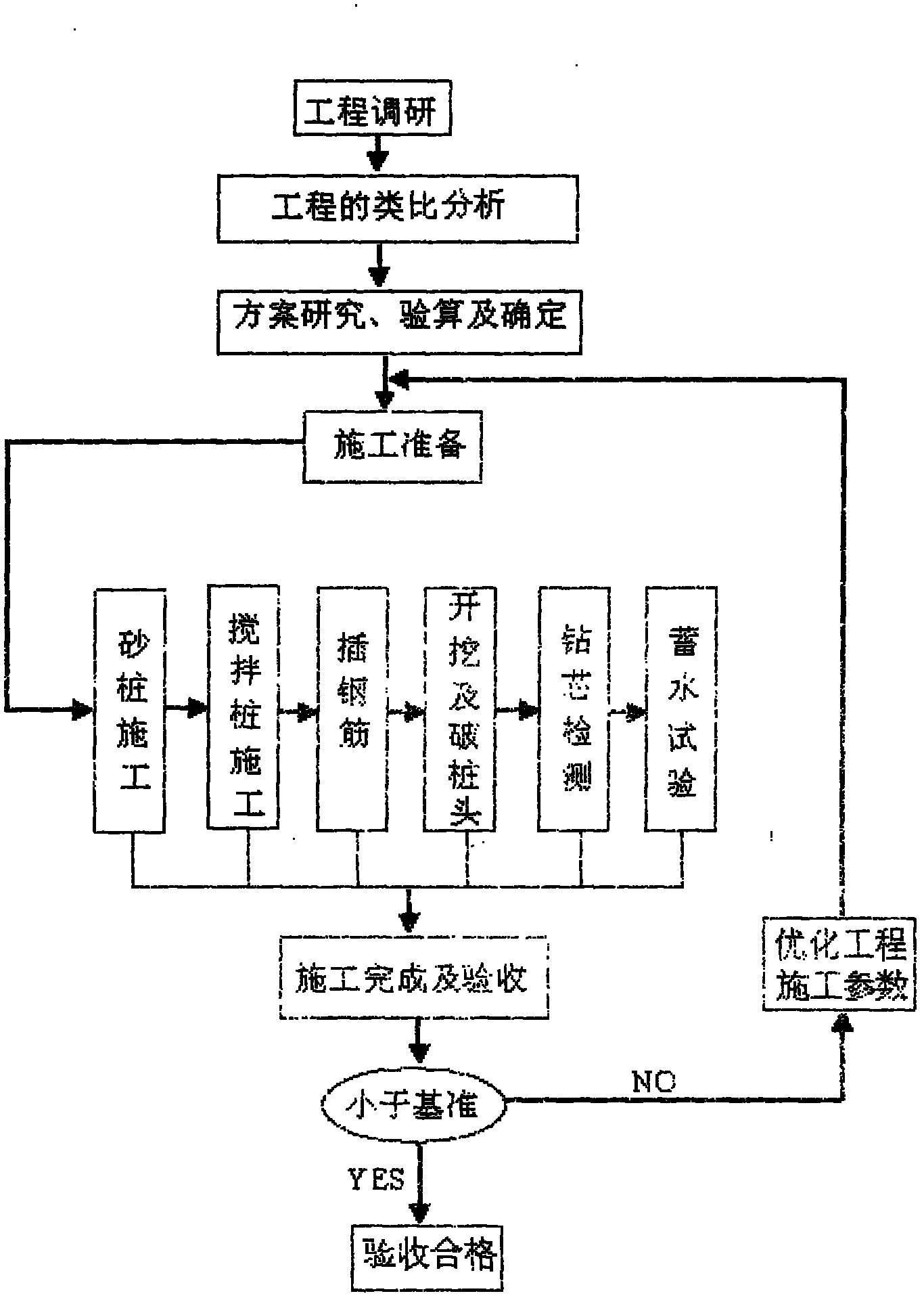

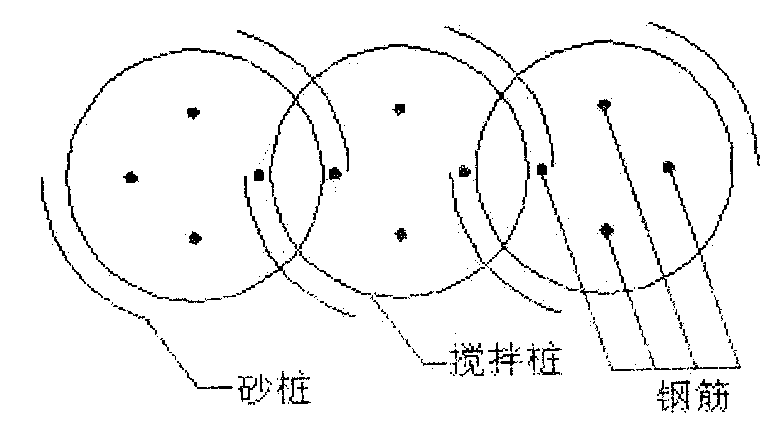

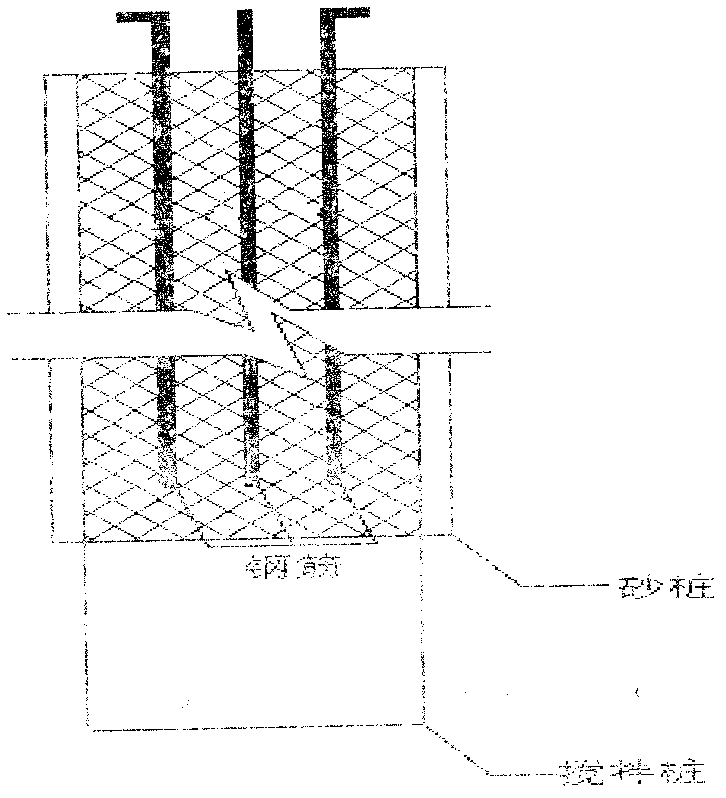

[0063] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

[0064] refer to figure 1 , figure 2 , image 3 , Figure 4 ; The present embodiment is the construction method of the Xihe sluice sand replacement type mixing pile cut-off wall in Zhongshan City, Guangdong Province, including the following main steps;

[0065] 1) Engineering research;

[0066] Xihe Sluice is a large sluice on Dawei, Zhongshun. It is located at the west exit of Shiqi River at the junction of Shenwan Town and Banfu Town, Zhongshan City, and is adjacent to Modaomen Waterway of Xijiang River. The main task of the reconstruction of the Xihe Sluice is to build a new 10-hole 15-meter-per-hole sluice and a IV-class ship lock on the old channel on the left side of the old sluice.

[0067] The foundation of Xihe Sluice is deep silt soft soil, mainly composed of silt, silty soil layer and sand layer. The silt layer is 30m-40m thick, and the strong (me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com