Device for testing vertical rigidity performance of motorcycle frame

A test device, motorcycle technology, applied in the direction of measurement device, vehicle test, machine/structural component test, etc., can solve the problems of unfavorable new products, permanent deformation, large investment, etc., to solve the vertical stiffness performance test of the frame The needs of evaluation, the effect of simple and reasonable structure and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

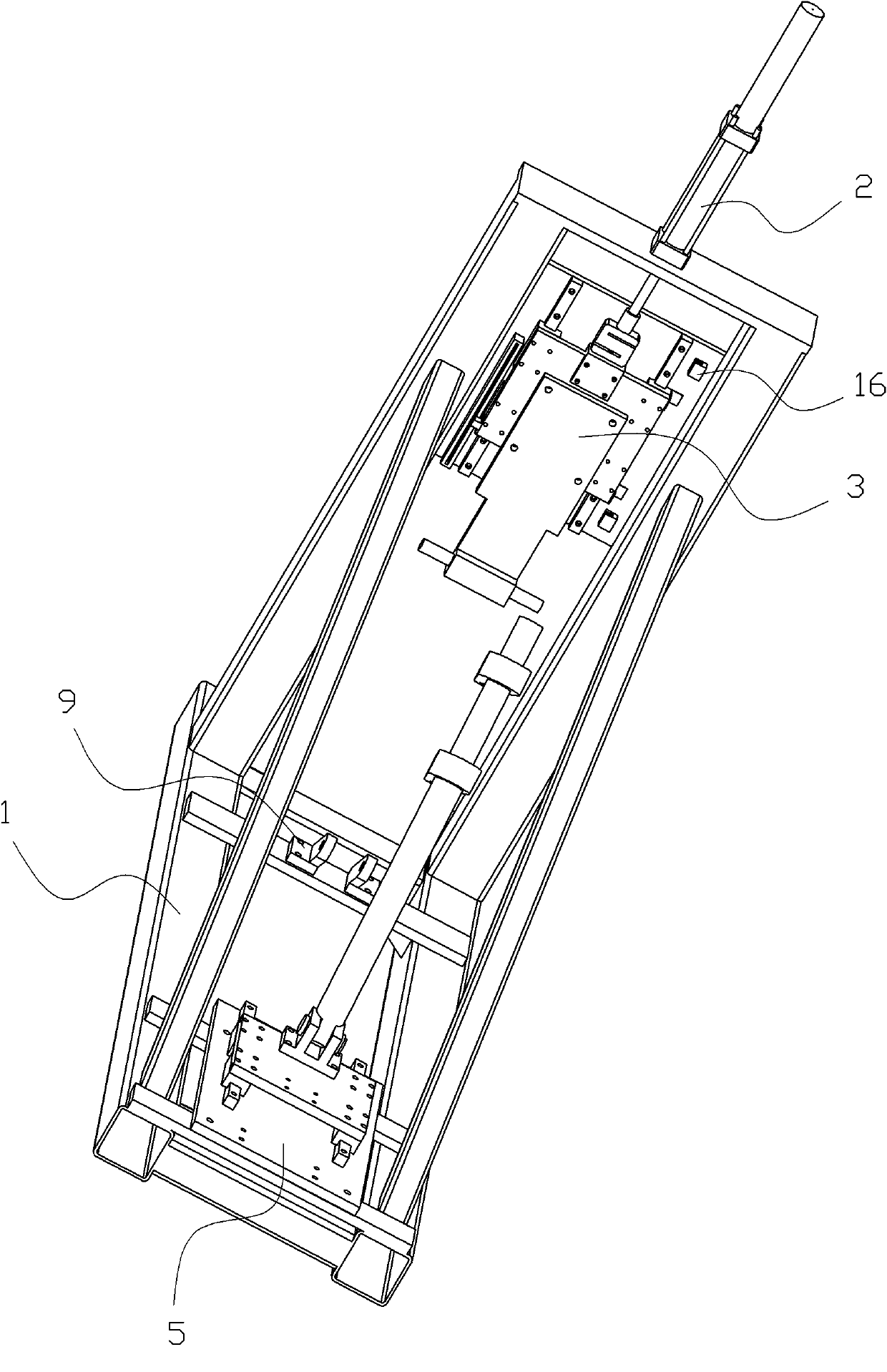

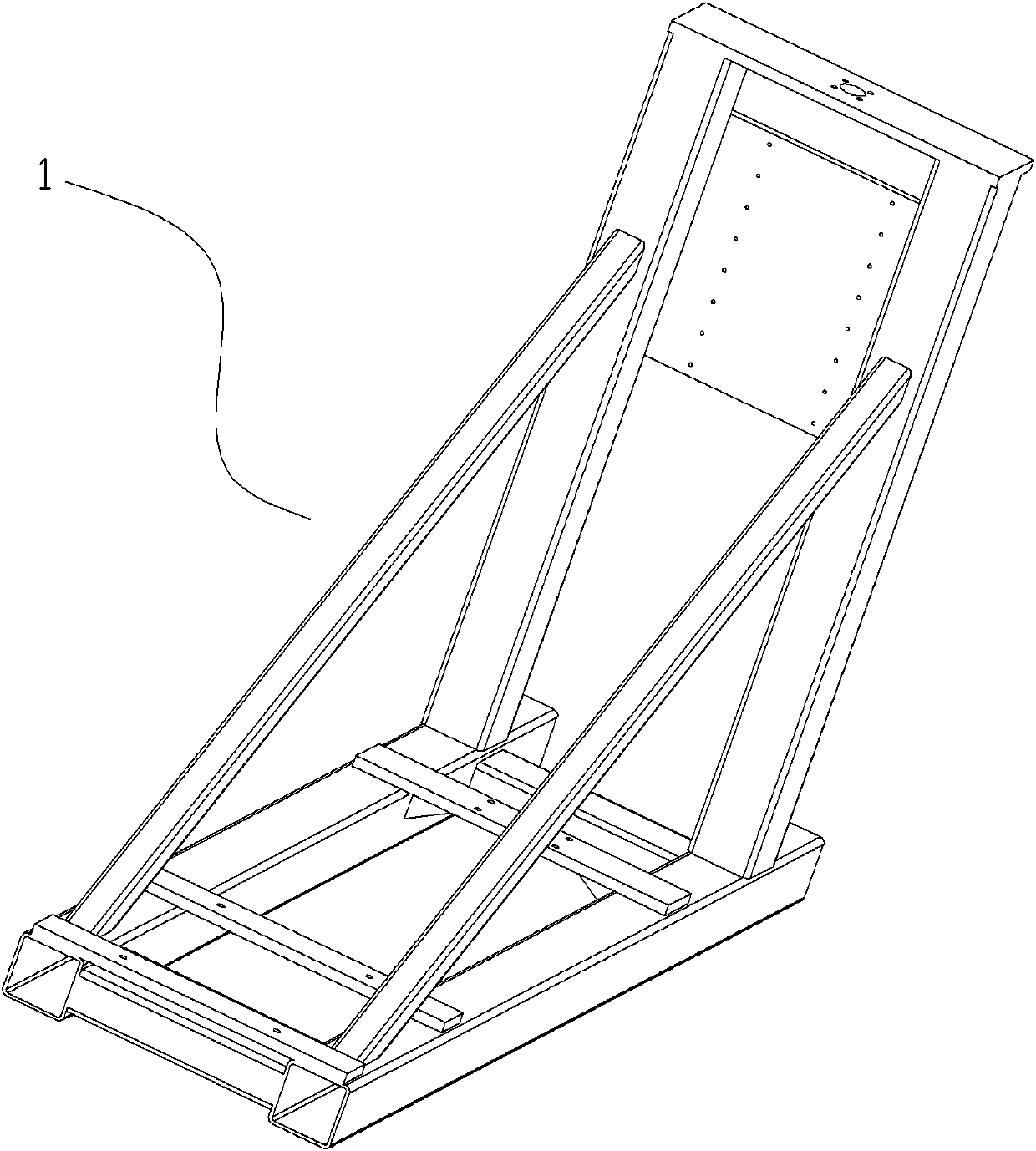

[0026] refer to Figure 2~Figure 10 , a motorcycle frame vertical stiffness performance testing device of the present invention, comprising a base 1, the vertical frame of the base 1 is fixed with a pressure cylinder 2, and the pressure cylinder 2 is used to generate road simulation for the motorcycle frame 20 to be tested Vertical pressure; the end of the piston rod of the pressure cylinder 2 is connected with a rear pressure plate seat 3 for applying a simulated vertical pressure to the motorcycle frame 20. Preferably, the pressure cylinder 2 is connected with the rear pressure plate seat 3 through a pressure sensor 11, and the pressure sensor 11 passes through The sensor support 12 is fixedly connected to the rear pressure plate seat 3, the simulated vertical pressure generated by the pressure cylinder 2 is transmitted to the rear beam 201 of the motorcycle frame 20 through the rear pressure plate seat 3, and a grating ruler is installed on a vertical side of the rear pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com