Compound four-connecting rod testing machine for mechanical properties of tire

A technology for tire mechanical properties and testing machine, which is applied in the field of indoor tire mechanical properties testing devices, can solve the problems of large discreteness, high cost, inaccurate test data, etc., and achieves the effects of ensuring accuracy, simple and reasonable structure, and easy manufacturing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

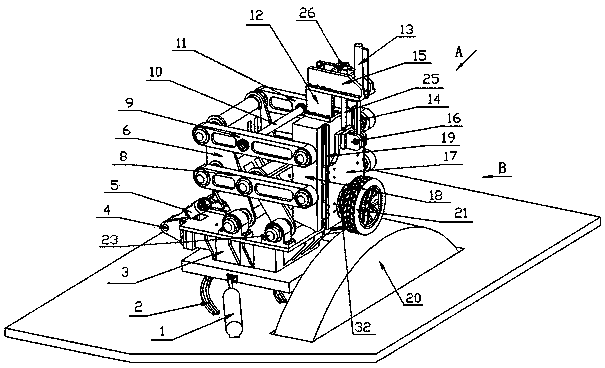

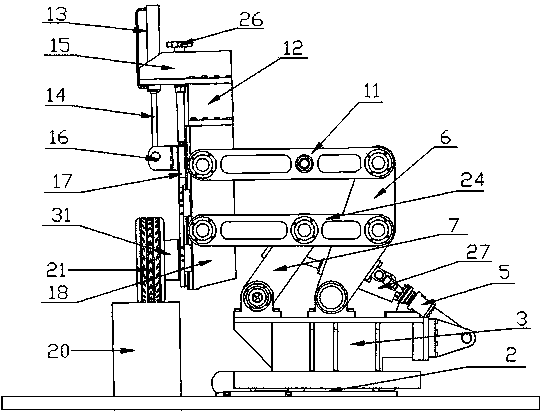

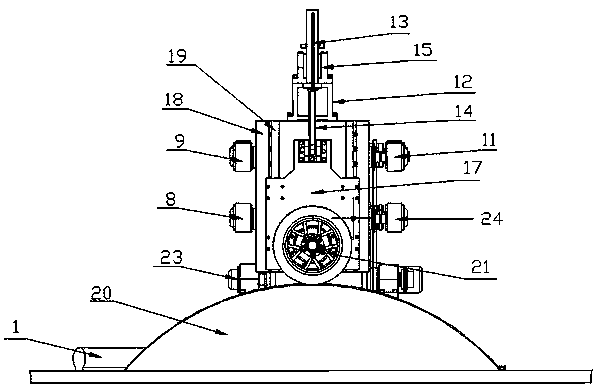

[0025] attached by figure 1 , 2 , 3 shows: the testing machine includes an arc-shaped guide rail device composed of a base hydraulic cylinder 1 and an arc-shaped guide rail 2, and consists of a base 3, four connecting rods 8, 9, 11, 24, a large pendulum mechanism 6, The composite four-bar linkage mechanism assembly composed of the small pendulum mechanism 7 is composed of the box body 18, the guide rail 19, the slide plate 17, the hydraulic cylinder 13, the hydraulic cylinder ejection rod 14, the hydraulic cylinder connecting platform 15, and the upper transition platform 12. Skateboard part assembly, six-component force sensor and drive brake assembly composed of six-component force sensor 31, drive brake device 35, composed of drum type test bench 20 or flat belt type test bench 28 or flat type test bench 29 to simulate the road surface device.

[0026] The base 3 is set on the arc guide rail 2, the base hydraulic cylinder 1 is fixedly connected to the base 3, and the base...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com