Assembled variable dimension direct shearing compression apparatus

A size-changing and assembled technology, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of lack of combined shearing and compression of variable sizes, inability to realize sample size changes, small reaction force, etc., to achieve light weight, The effect of low cost and easy processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

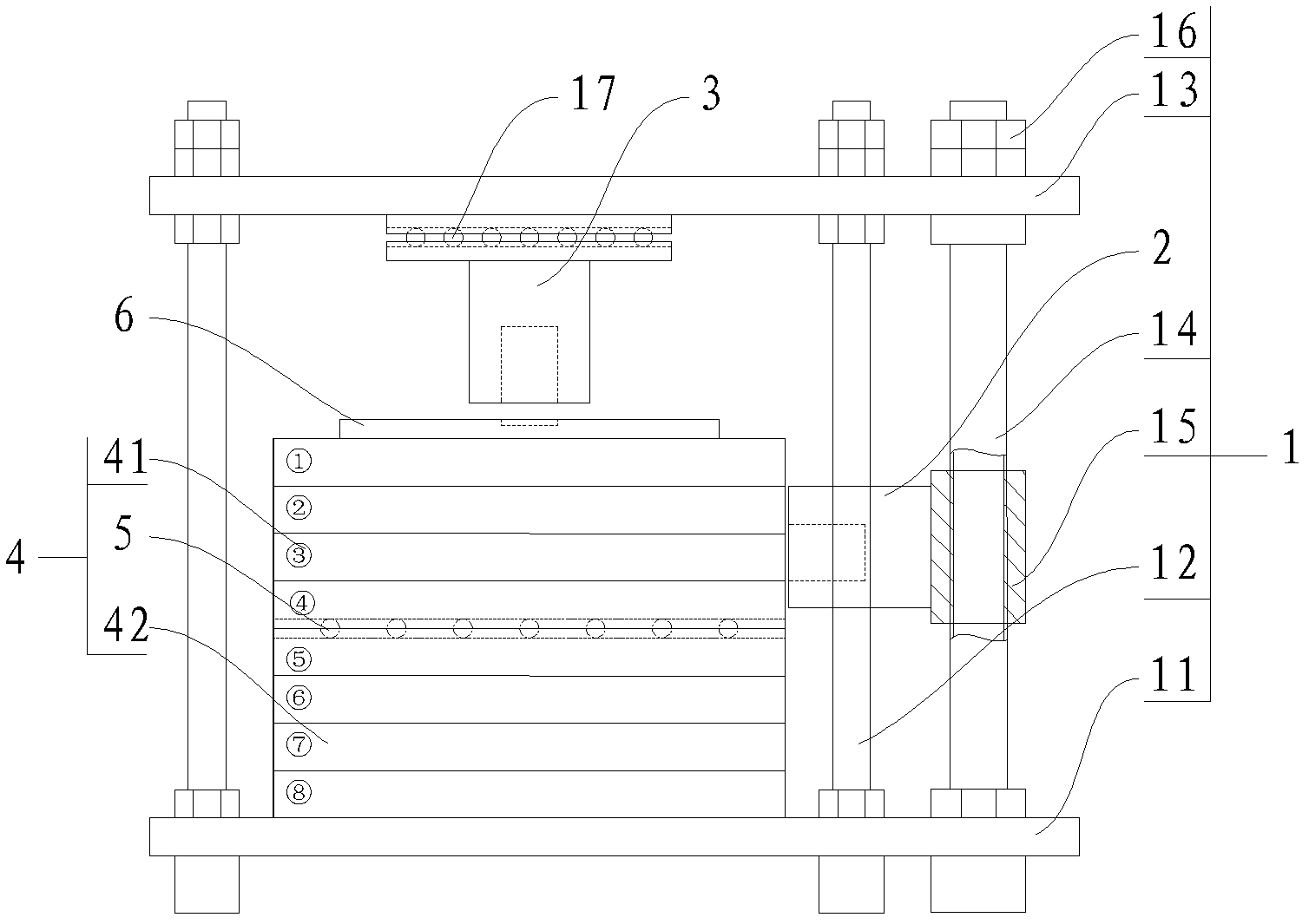

[0050] Such as Figure 1 to Figure 15 As shown, the assembled variable size direct shear compression instrument of the present invention includes the standard size of the laboratory direct shear test. After the shear plane is artificially set, several levels of vertical pressure can be applied to the soil and soft rock samples. Shear or compression tests can be carried out on the load, and shear tests can also be carried out on the structural surface of the rock mass.

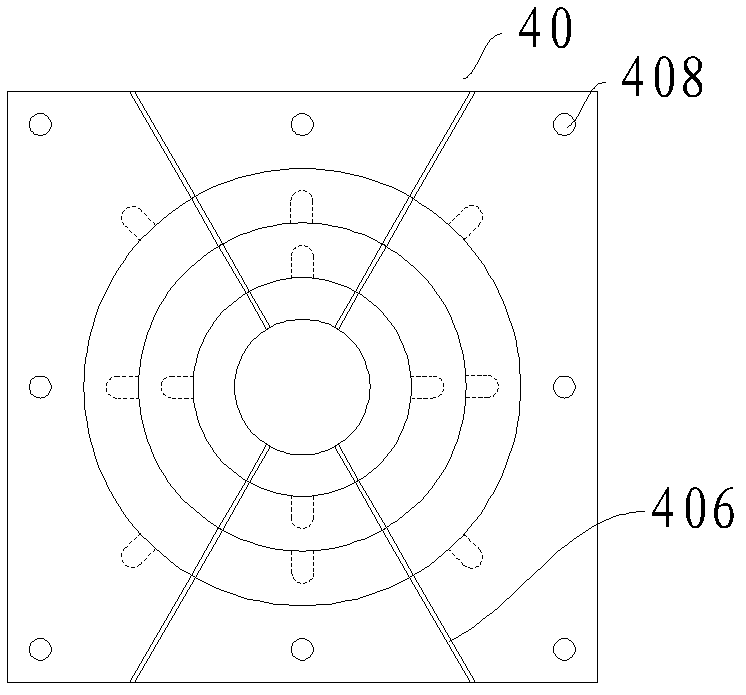

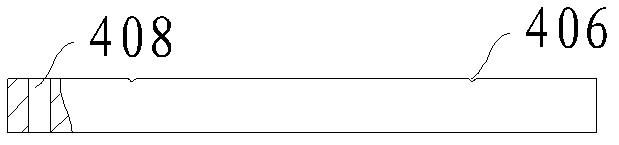

[0051] First, use a steel plate with a thickness of 2.5 cm to make eight sets of sample box rigid assemblies 40 numbered ① to ⑧, that is, the thickness of the sample box rigid assemblies 40 used to form the upper shear box 41 and the lower shear box 42 is 2.5 cm. cm, each set of sample box rigid assembly 40 is composed of four concentric steel rings, the outer edge of the outermost steel ring is a square, with a side length of 27 cm, and the center of the center is taken out as a cylinder with a diameter of 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com