Method for realizing digital signal processor (DSP) control over intermediate frequency single-phase generator inverter

A technology of a single-phase generator and an implementation method, which is applied to the starter, motor generator/starter, etc. of a single single-phase induction motor, and can solve problems such as the failure of the motor to start normally and current distortion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

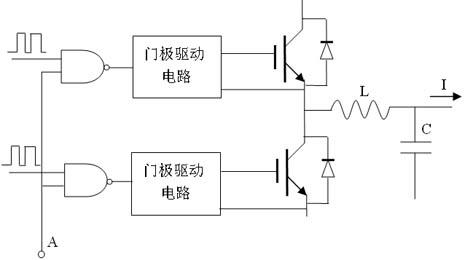

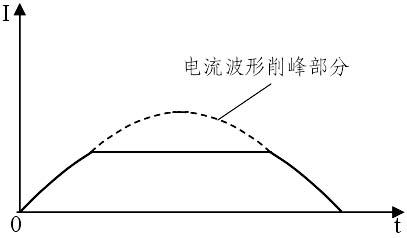

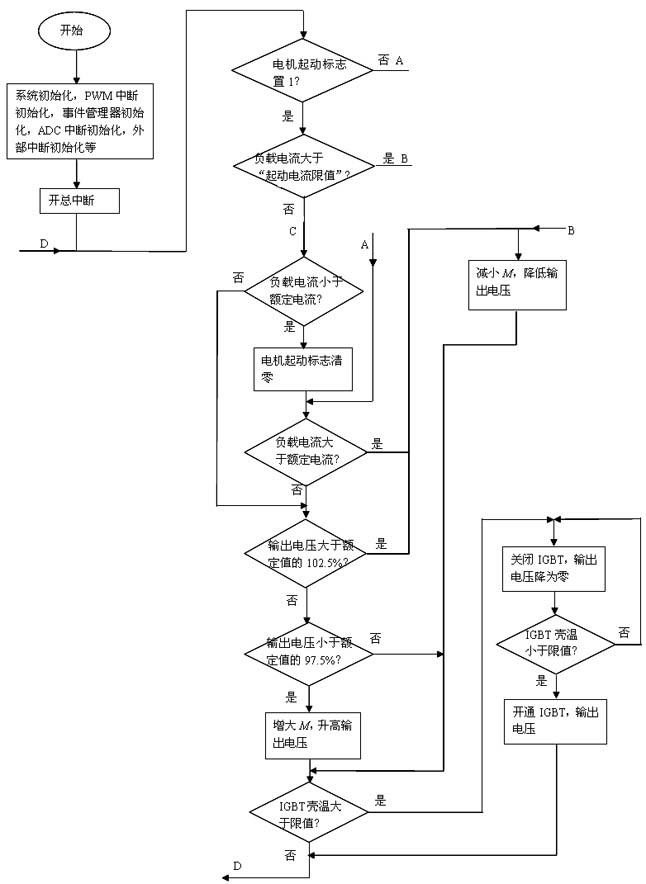

[0017] The invention provides a method for realizing DSP control of an intermediate frequency single-phase generator inverter, which is characterized in that: by detecting the current value of the inverter in the process of starting the motor, an interrupt signal is generated to make the DSP control software of the system Transfer to an interrupt subroutine; the interrupt subroutine first forces the IGBT device of the system to close, and clears the PWM sampling point sequence number of the system and marks the motor at this time as the load in the starting state, and then deeply lowers the PWM of the system. degree of modulation M . Continue to dynamically adjust according to the magnitude of the starting current after the interrupt subroutine ends and returns to the main program M , so that the adjusted output voltage of the inverter is adapted to t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com