Electromagnetic heating closed electric furnace

A closed, electromagnetic technology, applied in the direction of induction heating, coil devices, etc., can solve problems such as insulation material failure, panel electrification, personal injury, etc., achieve high electromagnetic conversion efficiency, improve safety performance, and save electricity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

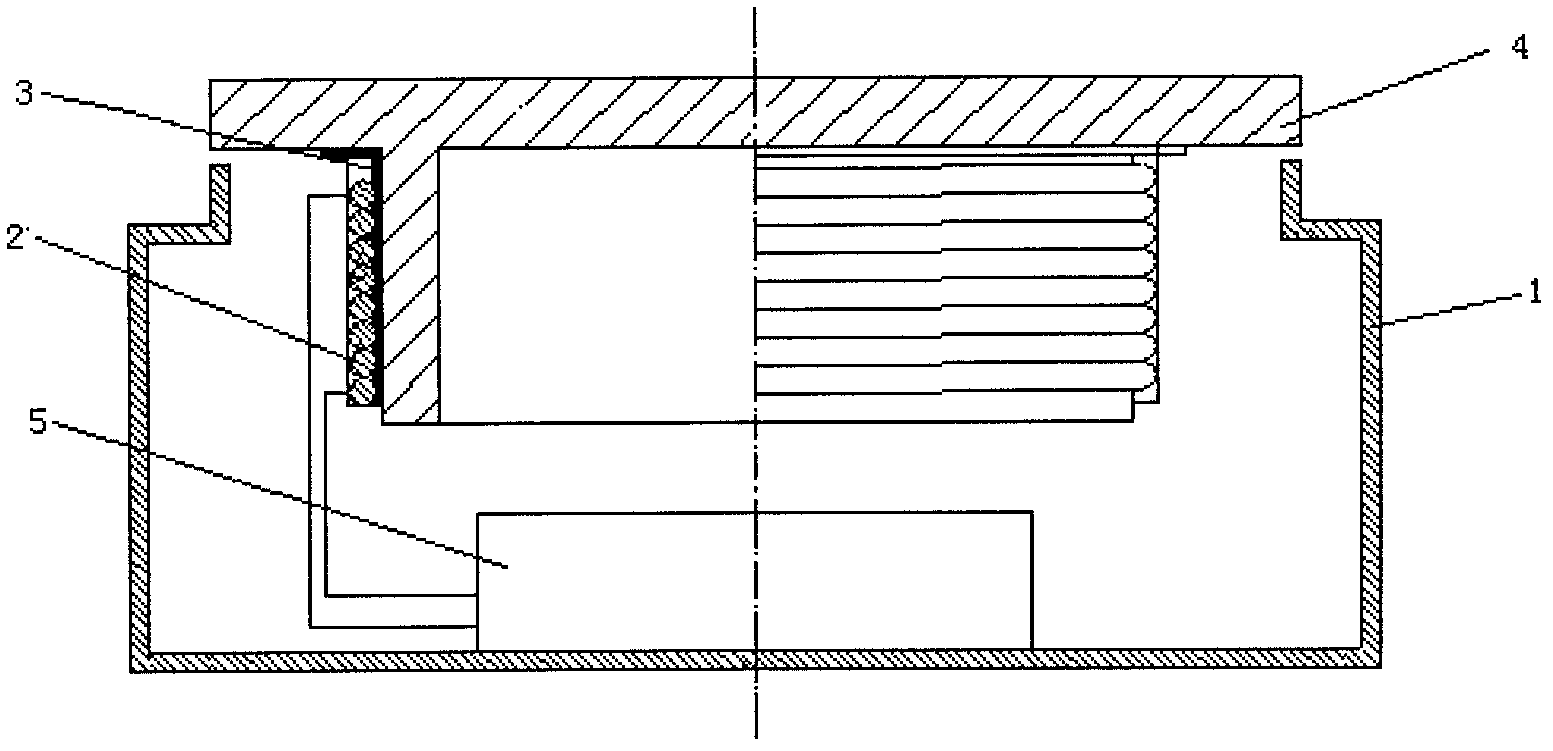

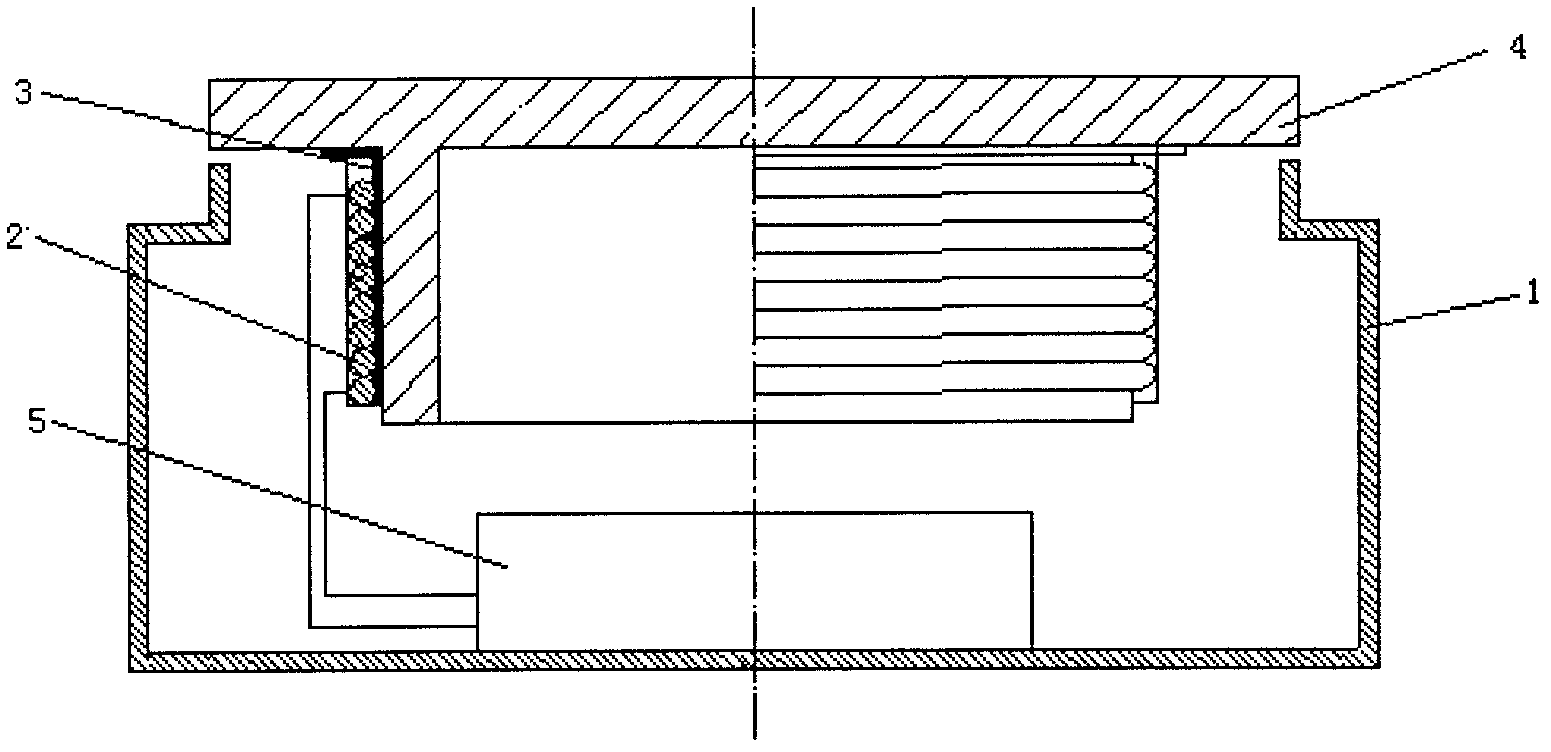

[0012] Embodiments of the electromagnetic heating closed electric furnace of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0013] Referring to FIG. 1 , the electromagnetic heating closed-type electric furnace provided by the present invention includes a casing 1 , a panel 4 , an insulating plate 3 in the casing 1 , a coil 2 and a control circuit 5 . The panel 4 is supported above the housing 1 . The panel 4 is made of ferromagnetic material, such as stainless steel, cast iron and so on. The cross-sectional diameter of the wire used in the coil 2 is 4.5 mm, which is wrapped by a layer of glass fiber wires with a diameter of 0.5 mm after stranding a plurality of high-temperature-resistant enamelled copper wires. The outer surface of the coil 2 has a resin Sealing layer. The heat insulation board 3 is a glass fiber board or an asbestos board, and its thickness is less than 3 mm.

[0014] Both the longitudinal section o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com