Adhesive material having redetachability

A technology of adhesive materials and peel strength, applied in the direction of film/sheet adhesives, adhesives, thin material processing, etc., can solve problems such as foaming, interface foaming, and adhesive sheets cannot withstand air pressure, etc., to achieve Satisfies the effect of re-peelability and

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

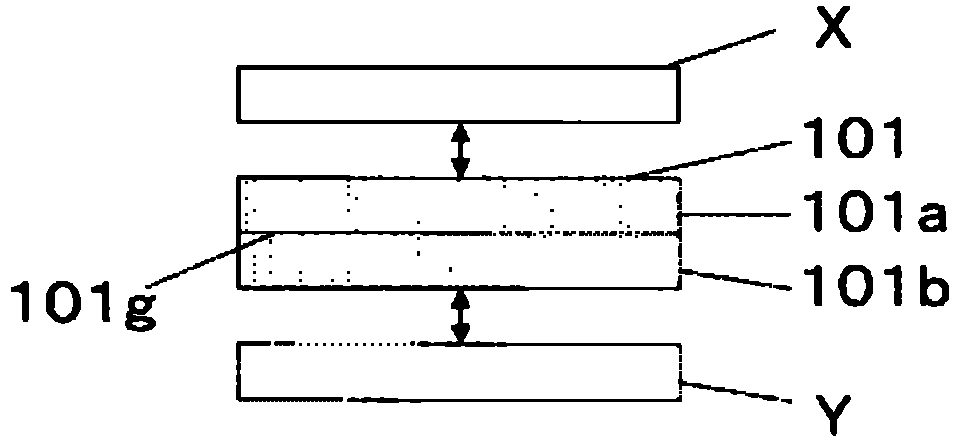

[0045] Such as figure 1 As shown, the adhesive material 101 (referred to as "this adhesive material 101") of the first embodiment includes at least two adhesive layers 101a, 101b, and the adhesive material has the following configuration: These adhesive layers 101a Between , 101b is an interface (internal peeling interface 101g) that can be peeled on a surface different from the bonding surface of the adhesive material and the adherend.

[0046]In this adhesive material 101, by making the interlayer peeling strength between the adhesive layers 101a, 101b smaller than the peeling strength at the sticking surface of the adherend X and the adhesive layer 101a, and the peeling strength between the adherend Y and the adhesive The peeling strength at the sticking surface of the mixture layer 101b can make the internal peeling interface 101g between the adhesive layers 101a, 101b.

[0047] More specifically, it can be modified by, for example, coating a known release agent on the su...

no. 2 Embodiment approach

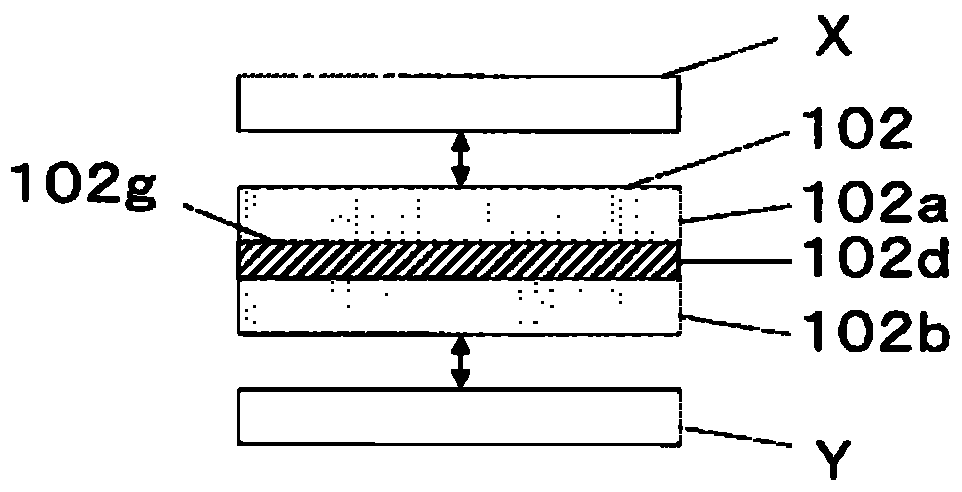

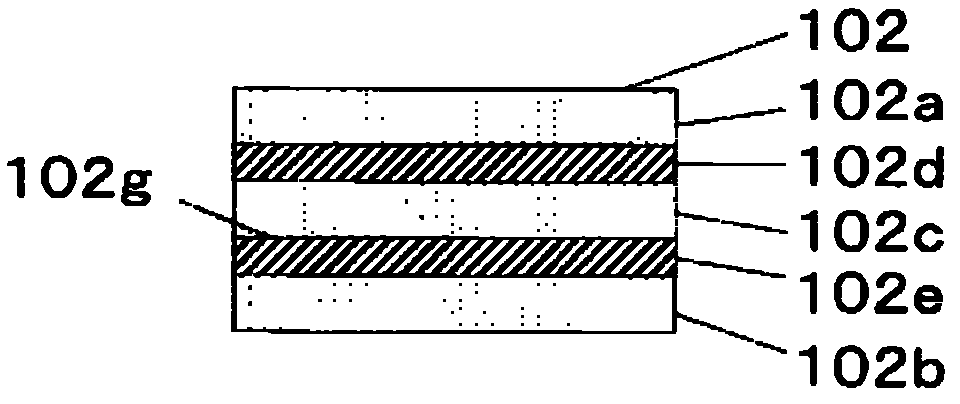

[0052] The adhesive material 102 (referred to as "this adhesive material 102") according to the second embodiment is a material having the following structure: having at least two adhesive layers 102a, 102b, and at least one or more adhesive layers bonded to these adhesive layers. One of the interfaces between the layer 102d and the adhesive layers 102a, 102b becomes an internal peeling interface.

[0053] For example, it may be the following structure: at least two layers of adhesive layers 102a, 102b, and at least one base material layer 102d, between the base material layer 102d and at least one layer of adhesive layer 102a, a The interface (internal peeling interface 102g) that is peeled is performed on a surface different from the adhesive surface of the adherend.

[0054] As an example, it can be as figure 2 In the shown configuration, a base material layer 102d exists between two adhesive layers 102a and 102b, and an internal peeling interface 102g is provided between...

no. 3 Embodiment approach

[0073] Such as Figure 4 As shown, the adhesive material 103 according to the third embodiment (referred to as "this adhesive material 103") is provided with at least two adhesive layers 103a, 103b and at least two base material layers 103c, 103d, and is equipped with An adhesive material having a structure in which a peelable interface (internal peeling interface 103g ) is provided between the base material layer 103c and the base material layer 103d is provided on a surface different from the adherend surface.

[0074] In this adhesive material 103, in order to provide the internal peeling interface 103g between the base material layer 103c and the base material layer 103d, the peel strength between the base material layer 103c and the base material layer 103d should be lower than that of the adherend X and the adhesive. The peel strength of the agent layer 103a, the peel strength of the adherend Y and the adhesive layer 103b, the peel strength of the base material layer 103...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com