Plastic pipe extrusion molding apparatus

An extrusion molding, plastic pipe technology, applied in the direction of tubular items, other household appliances, household appliances, etc., can solve the problems of declining pipe quality, affecting the use of pipes, etc., to improve the effect, improve production efficiency and economic benefits, high quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment, the present invention is described in further detail, but does not constitute any restriction to the present invention:

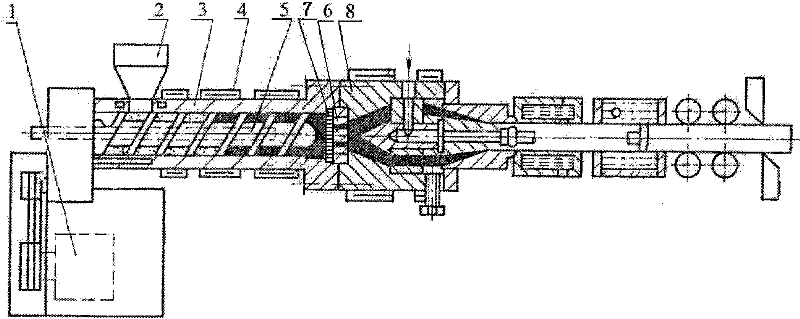

[0014] Such as figure 1 , a plastic extrusion molding device, mainly including a power mechanism 1, a hopper 2, a barrel 3, a barrel heater 4, a screw 5, a head 7, a sizing device, a cooling device, a traction device, and a cutting device, etc., said A diverter plate 6 is provided at the joint between the barrel 3 and the head 7, and a filter 8 is provided at the junction between the diverter plate 6 and the barrel 3; the filter 8 is arranged on the diverter plate 6; The filter screen 8 is a stainless steel wire filter screen.

[0015] The plastic extrusion molding device of the present invention selects filter screens with different mesh numbers for different material flows: when the viscosity of the material flow is high and the stability is poor, a filter screen with a large mesh numb...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap