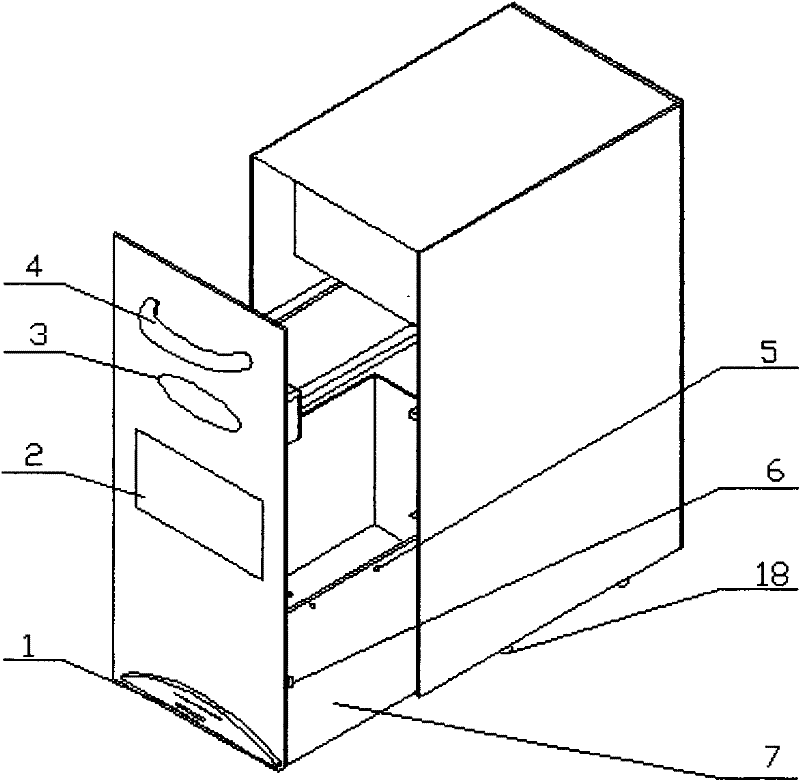

Kitchen waste compressor

A technology for waste bins and kitchens, applied in trash cans, garbage collection, waste collection and transfer, etc., can solve the problems of unpleasant smell, leakage of garbage transportation, small storage space, etc., to save land and human resources, avoid secondary Environmental pollution, effect of preventing scattering and leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

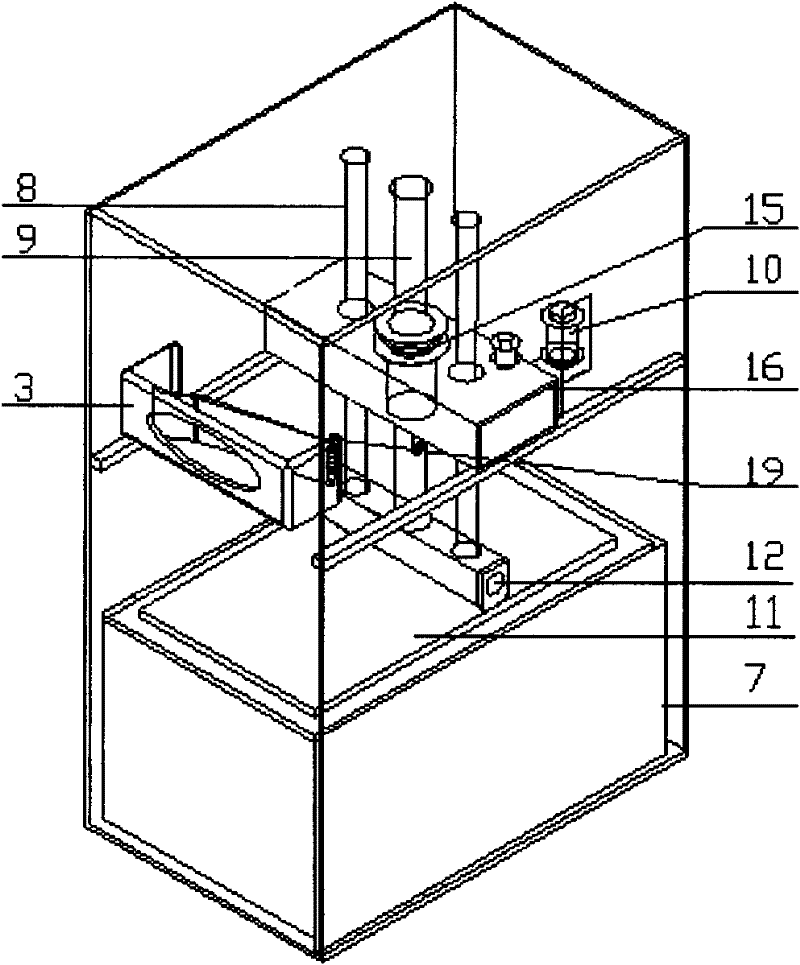

[0018] The garbage disposal door (2) is connected to the position sensor, which can be opened and rotated inward. When the compressor start switch (1) is activated, the signal received by the IO circuit board is processed by the microcomputer control circuit, and then transmitted back to the IO circuit board, and the connection is locked. The control device receives an instruction to lock the throwing door (2), and is confirmed by the closed position sensor, and the garbage drawer is locked.

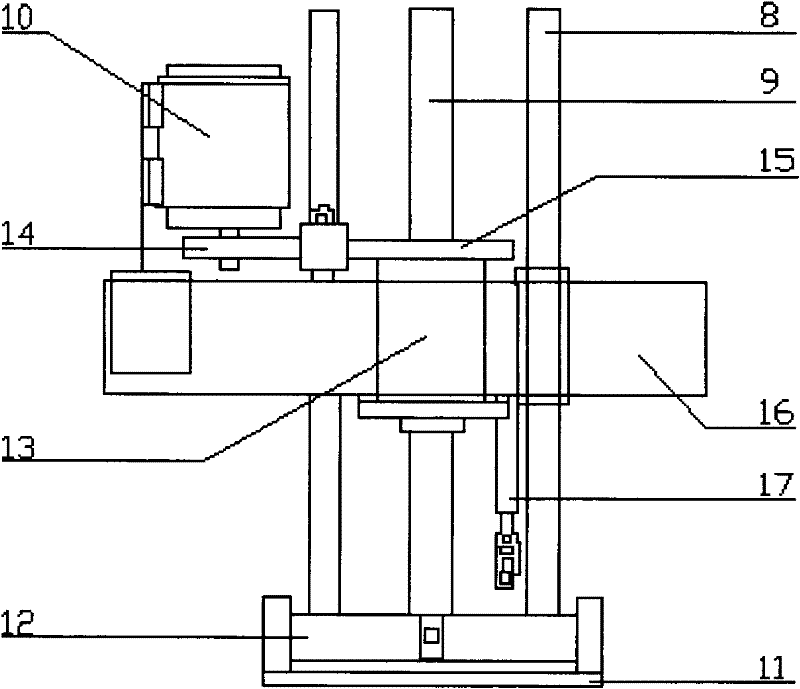

[0019] After the garbage throwing door and the garbage drawer box are locked, the IO circuit board receives the signal, passes it to the IO circuit board after being processed by the microcomputer control main board, and the motor (10) connected to the IO circuit board rotates forward, and the small motor connected by the motor Belt pulley (14) drives belt pulley (15) forward rotation, so the leading screw transmission device (13) that is connected with belt pulley forward rotation, drive...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com