Compacting device of yarns on weaving machine

A pressing device and yarn technology, applied in looms, textiles, textiles and papermaking, etc., can solve the problems of difficult circulation, poor product fastness, easy to break, etc., and achieve easy use, simple structure, and yarn The effect of moderate tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

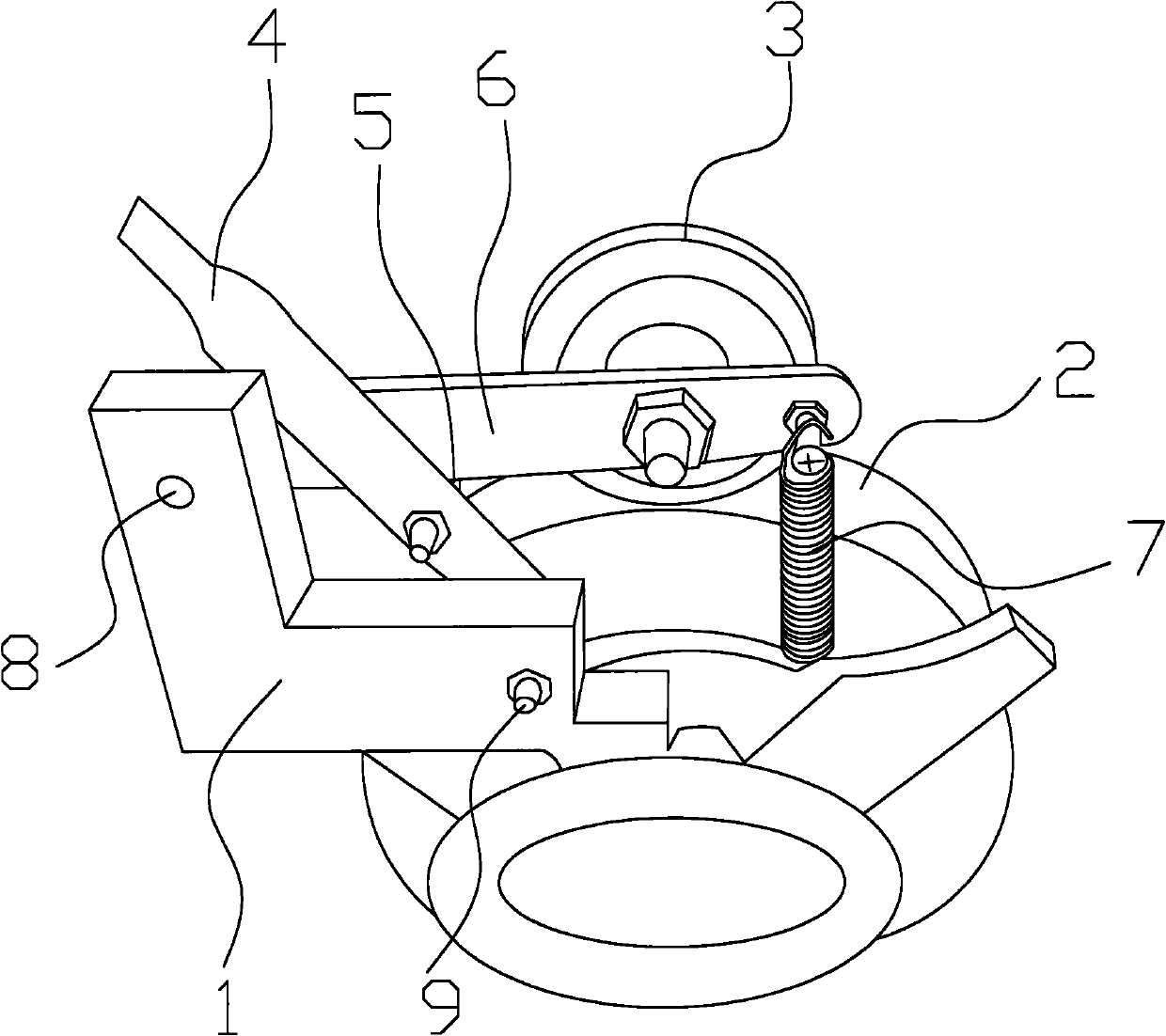

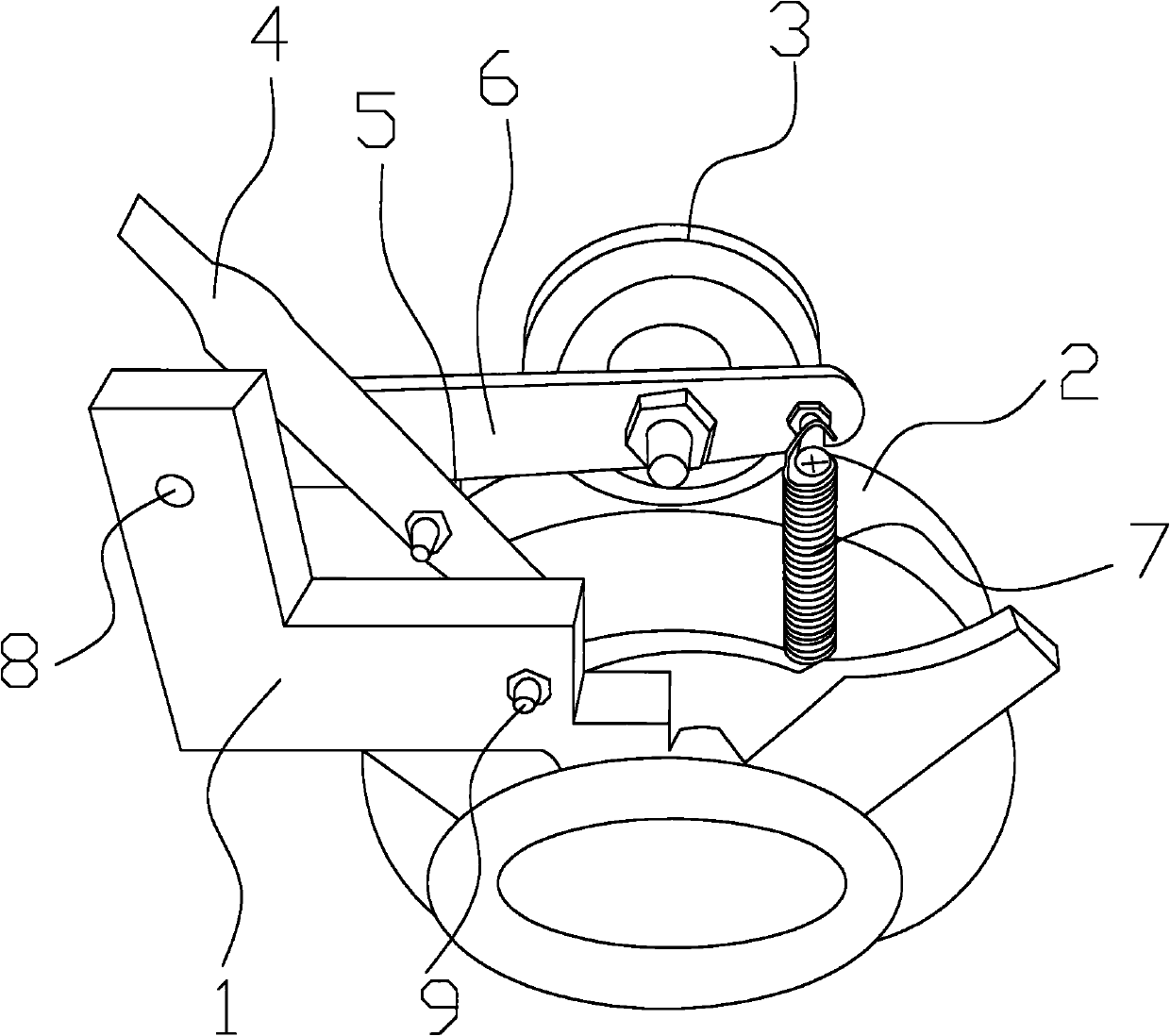

[0015] From attached figure 1 It can be seen from the structural diagram of the loom yarn pressing device that the present invention provides a loom yarn pressing device, which includes a main body 1, a yarn bearing wheel 2 rotatably mounted on the main body 1, and a rotatable The adjusting rotating arm 6 that the arm fulcrum 8 rotates, the adjusting rod 4 that can rotate around the adjusting rod fulcrum 9, the pressing wheel 3 that is installed on the free end of the adjusting rotating arm 6 and is tightened between the body 1 and the Adjust the spring 7 between the rotating arms 6, and form an adjusting block 5 in the middle of the adjusting ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com