Concrete crusher

A technology of concrete and crushers, applied in roads, road repairs, roads, etc., can solve problems that affect the smoothness of roads and take a long time, and achieve the effect of convenient operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

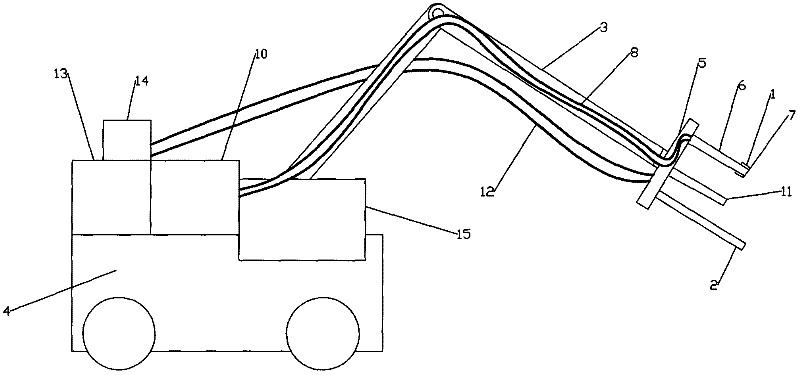

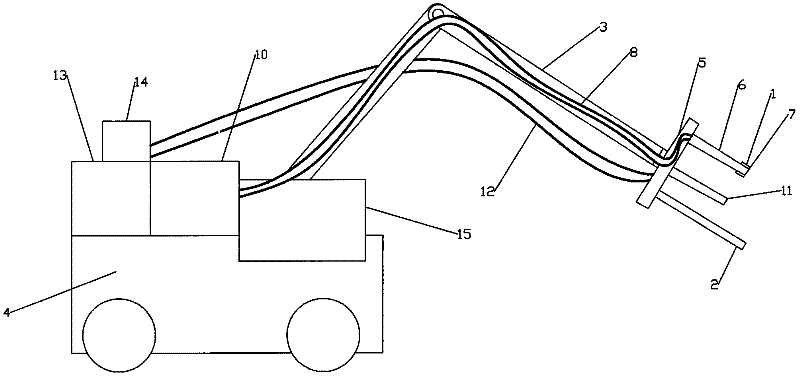

[0007] As shown in the figure, the concrete breaker provided by the present invention includes a high-temperature flame sprayer 1, an electric drill 2, a mechanical arm 3 and a transport device 4. The mechanical arm 3 is generally composed of two hinged metal rods, and the high-temperature flame sprayer 1 and The electric drill 2 is arranged at the end of the mechanical arm 3, and the mechanical arm 3 is arranged on the transportation device 4. The transportation device 4 is equipped with a control room 15, and the control room 15 is provided with an integrated circuit for controlling the high-temperature flame nozzle 1 and the electric drill 2. Control system, the end of the mechanical arm 3 is equipped with an electric control turntable 5, the electric drill bit 2 and the high-temperature flame nozzle 1 are arranged at the edge of the electric control turntable 5, the electric control turntable 5 is controlled by the integrated control system, and the electric control turntabl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com