Electric transmission line overhead wire outlet walker

A technology for transmission lines and overhead lines, applied in the direction of overhead lines/cable equipment, etc., which can solve problems such as heavy weight, personnel falling, and ladder falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In the following, the overhead walker for power transmission lines of the present invention will be further described in detail in combination with the accompanying drawings and specific embodiments.

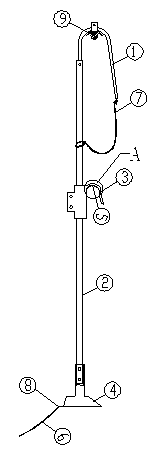

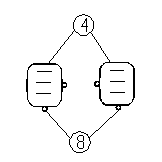

[0022] As shown in the figure, the walker for the overhead line of the transmission line of the present invention includes two connecting rods 2 arranged independently of each other, and the connecting rods 2 can be aluminum alloy hollow tubes; the upper end of each connecting rod 2 is provided with a main hook 1. The main hook 1 is the main load-bearing rod. It is hung on the overhead wire during operation, which can assist the operator to move to the working position on the overhead wire. The wire shield is lined with rubber; the front end of the main hook 1 is provided with a hasp hanging hole that can be hung with a safety rope. above; the central part of the connecting rod is provided with an auxiliary hook 3, and the inner side of the arc surface of the auxiliary ho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com