Device for detecting wear of apparatus and shield machine provided with same

A device and wear amount technology, applied in the device for detecting the wear of the device and in the field of shield machine, can solve the problems of high cost, sudden change of excavation parameters, delayed excavation construction period, etc., and achieve the effect of easy detection, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

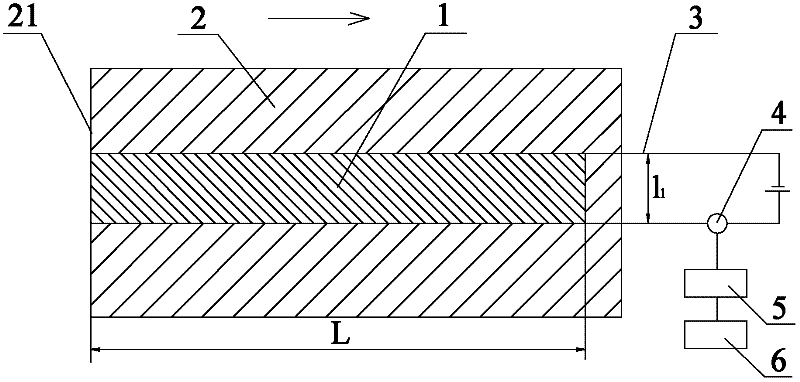

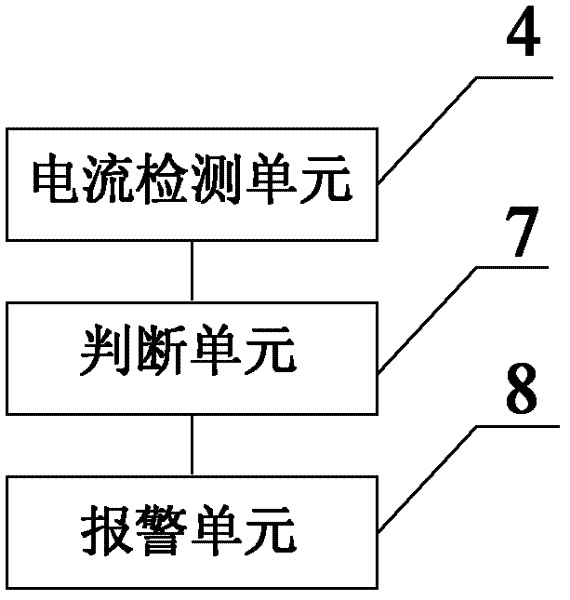

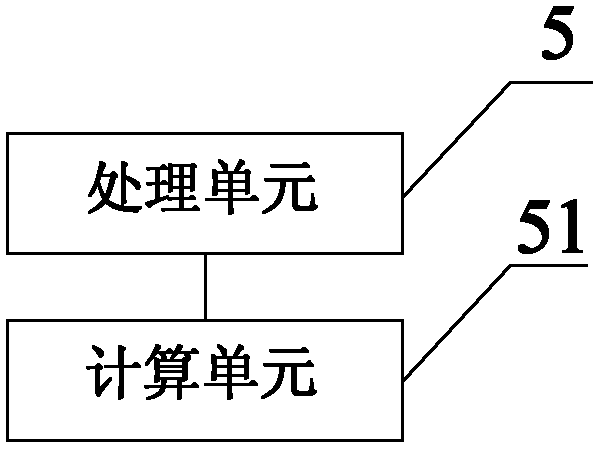

[0021] see figure 1 A first preferred embodiment of a device for detecting wear of an appliance according to the present invention is shown. As shown in the figure, the device for detecting wear of an appliance includes a resistor 1 connected to a constant pressure circuit. The resistance element 1 is installed on the tool 2 to be tested and can be worn synchronously with the tool 2. The tool 2 is usually made of metal, such as a tool for cutting or a cutter head for installing a tool. figure 1 , the direction indicated by the arrow is the wear direction of the appliance 2, the left end of the appliance 2 is the wear end 21, the initial position of the end of the resistance element 1 close to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com