Integrated device for in-situ generation and decomposition of hydrate sediments and permeability measurement thereof

A technology for in-situ generation of hydrate sediments, applied in measurement devices, permeability/surface area analysis, analysis materials, etc. Real simulation of historical deposition conditions and stress state of hydrate sediments to meet the requirements of high-precision testing, low cost, and easy cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

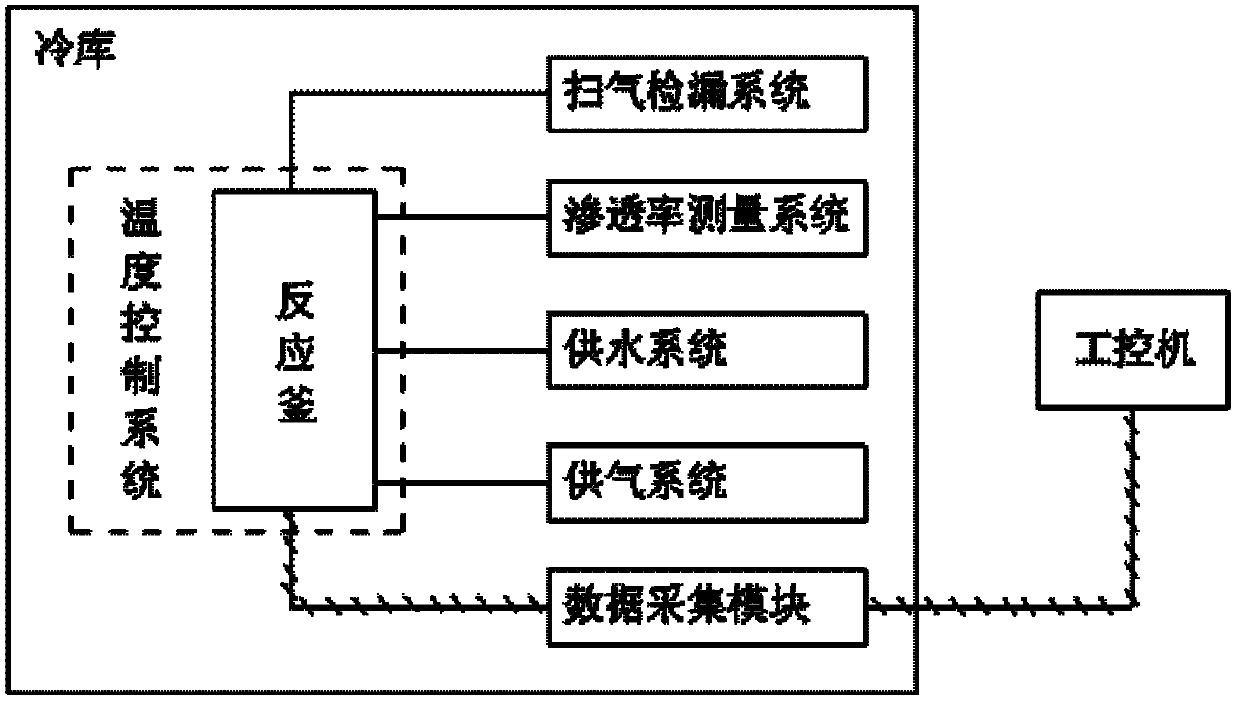

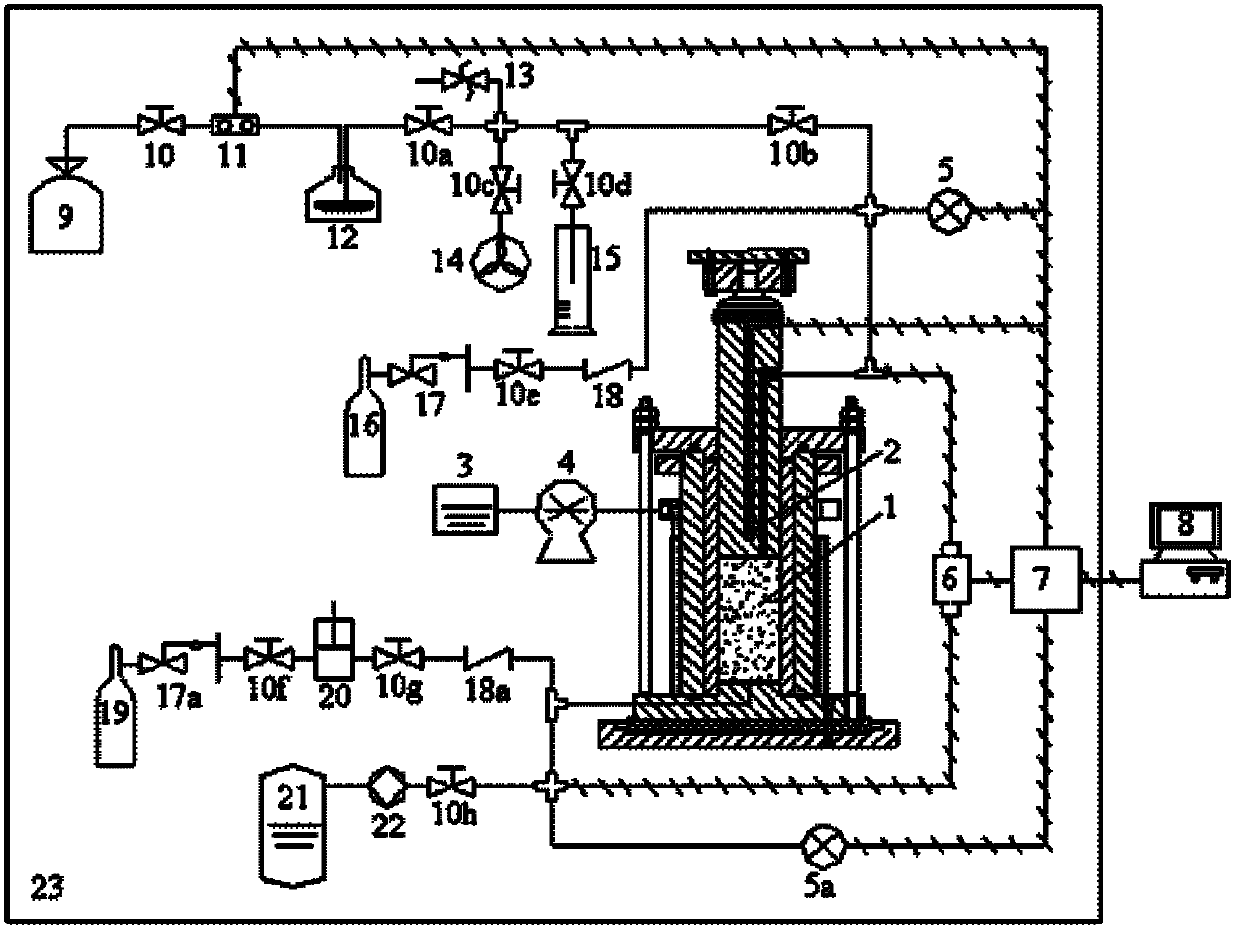

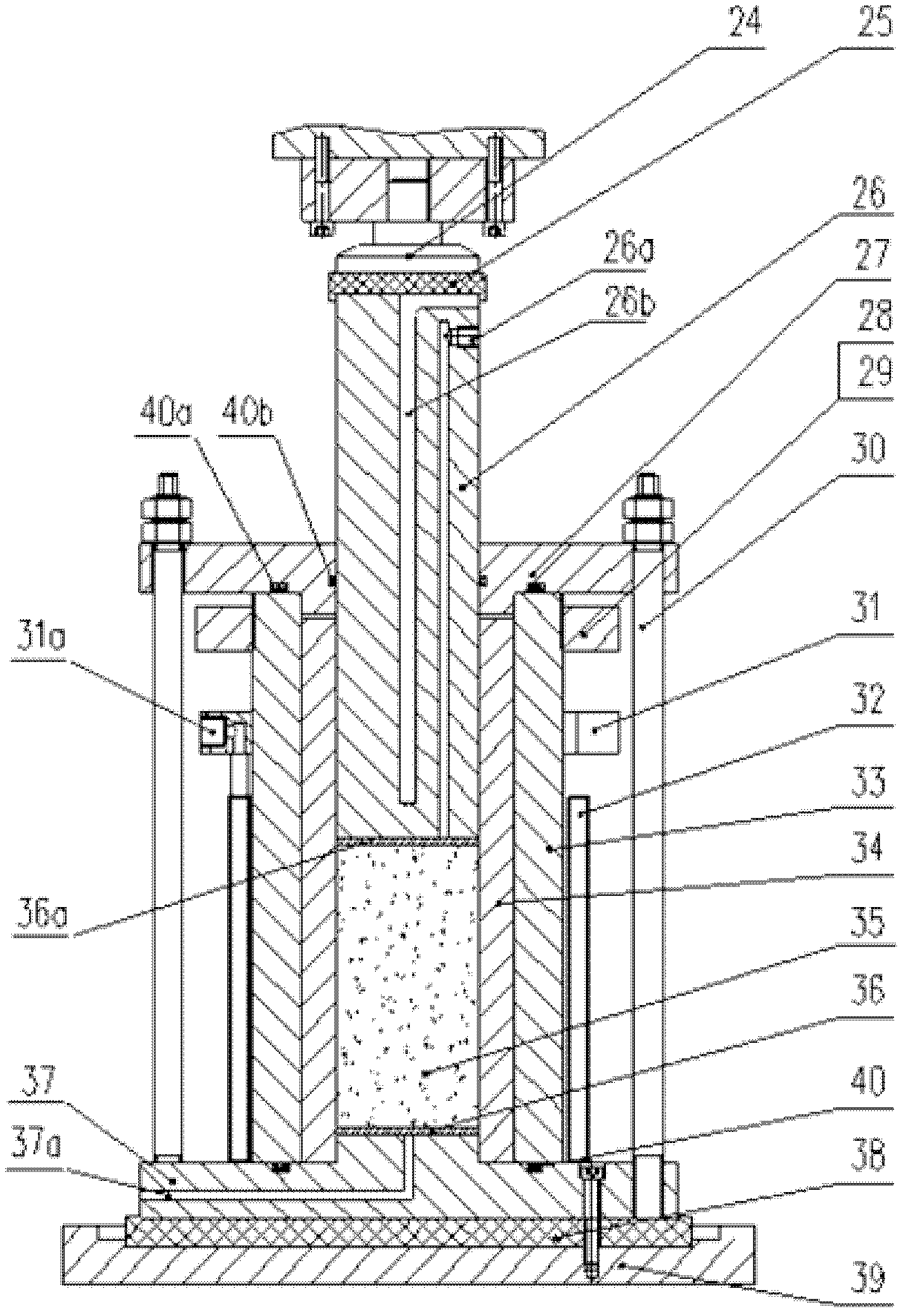

[0027] figure 1 Shown is the working principle diagram of an integrated device for in-situ generation and decomposition of hydrate sediment and its permeability measurement. The working process is: the device is tested after being checked by the scavenge gas leak detection system and does not leak. The system supplies methane gas to the reactor, and controls the pressure in the reactor through a constant pressure pump. The water supply system supplies distilled water to the reactor. The cold storage and constant temperature bath control the temperature required for the reaction. The working parameters during the reaction such as temperature, pressure signal, etc. All are collected and analyzed by the computer data acquisition system. After the hydrate is formed, the permeability measurement system is used to measure the permeability of the hydrate sediment or the hydrate sediment can be taken out and put into a triaxial testing machine for mechanical characteristics test.

[0028...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com