Photoelectric sensing detector based on seamless splicing and manufacturing method thereof

A seamless splicing, photoelectric sensing technology, applied in the field of radiation detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

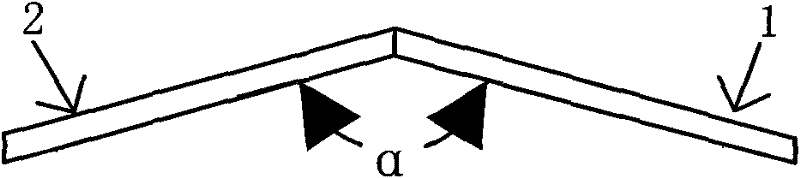

[0028] see figure 1 , which is a schematic cross-sectional view of two adjacent detector modules 1 and 2 in the photoelectric sensing detector based on seamless splicing of the present invention, the detector modules 1 and 2 are spliced into an angle shape in a seamless splicing manner, that is, the detector module The angle between 1 and detector module 2 is α, where 0<α<360°, and both detector module 1 and detector module 2 are photosensitive array modules, which can be coupled to the scintillator layer, and the structures of the two same.

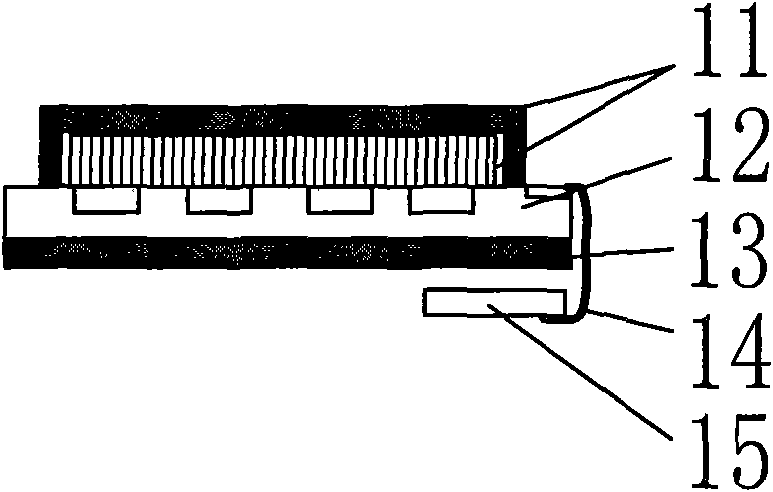

[0029] see you again figure 2 , which is a schematic diagram of the modular unit structure of the stitched detector. The detector module unit includes: a base plate 13 , a photosensitive element array 12 , a scintillator layer and an encapsulation layer 11 , a processing circuit 15 , and an interconnection circuit 14 and the like. It should be noted that if the array of photosensitive elements can directly detect radiation (ie X-ra...

Embodiment 2

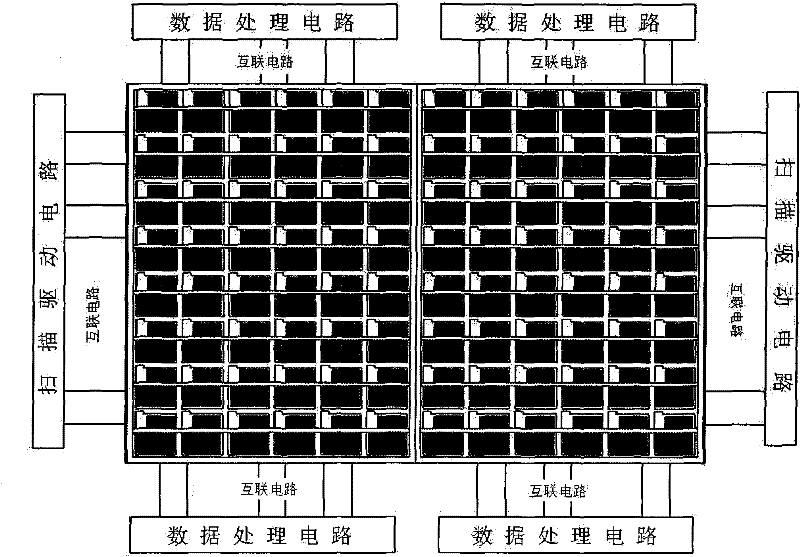

[0038] See Figure 5 , which is a schematic cross-sectional view of the detector modules 1', 2' and 3' in the photoelectric sensing detector based on seamless splicing of the present invention, and the detector modules 1', 2' and 3' are spliced into a seamless splicing manner Angled, that is, the angle between detector modules 1' and 2 is α1, and the angle between detector modules 2' and 3' is α2, where 0 Image 6 As shown, in the same detector module, the interconnection circuit connected to the scanning drive circuit and the interconnection circuit connected to the data processing circuit are arranged on opposite sides of the photosensitive element array module, so that the remaining opposite sides can be used for seamless splicing, Further, a photoelectric sensor detector formed by seamless splicing of three or more photosensitive element array modules is formed.

Embodiment 3

[0040] See Figure 7a with Figure 7b , which is a schematic cross-sectional view of the detector modules 1"2", 3" and 4" in the photoelectric sensing detector based on seamless splicing of the present invention, between the detector modules 1" and 2", and the detector module 3" and 4" is α1; the angle between detector modules 1" and 3" and between detector modules 2" and 4" is α2, where 0 Figure 4 As shown, in the same photosensitive element array module, interconnection circuits are provided only on both sides, and the interconnection circuit connected to the scanning drive circuit and the interconnection circuit connected to the data processing circuit are arranged on adjacent two sides of the photosensitive element array module. A photoelectric sensing detector comprising four detector modules is formed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com