Mask plate box capable of measuring size of mask plate protection film

A mask plate and protective film technology, which is applied in the manufacture of electrical components, semiconductor/solid-state devices, circuits, etc., can solve the problems of no protective film size, increased process cost, long time period, etc., to achieve simple and fast measurement and reduce use errors The risk of the mask plate and the effect of saving process cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

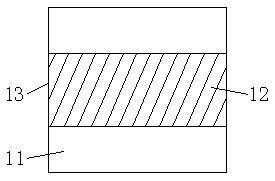

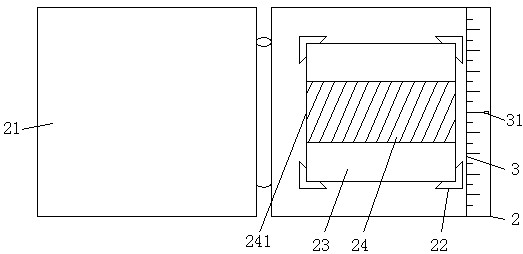

[0015] figure 2 It is a structural schematic diagram of the transparent mask box in the mask box that can measure the size of the mask protective film in the present invention; as figure 2 As shown, the present invention is a reticle box capable of measuring the size of the reticle protective film:

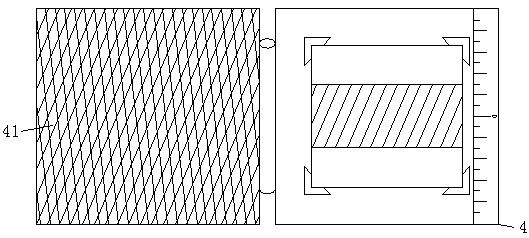

[0016] On the inner wall of the mask box 2 near the placement position of the mask plate, a scale 3 parallel to the extension line of the narrow side 421 of the mask plate protective film 42 on the mask plate 4 placed therein is provided. Wherein, the scale value of the scale 3 is on the order of millimeters, and the center line 31 of the scale 3 is on the same straight line as the center line of the narrow side 241 of the mask plate protective film 24, and the center of the scale is set as zero point, extending to both ends evenly set with the sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com