Fuel filler door module

A fuel tank cover and segment technology, applied in the field of fuel tank cover modules

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

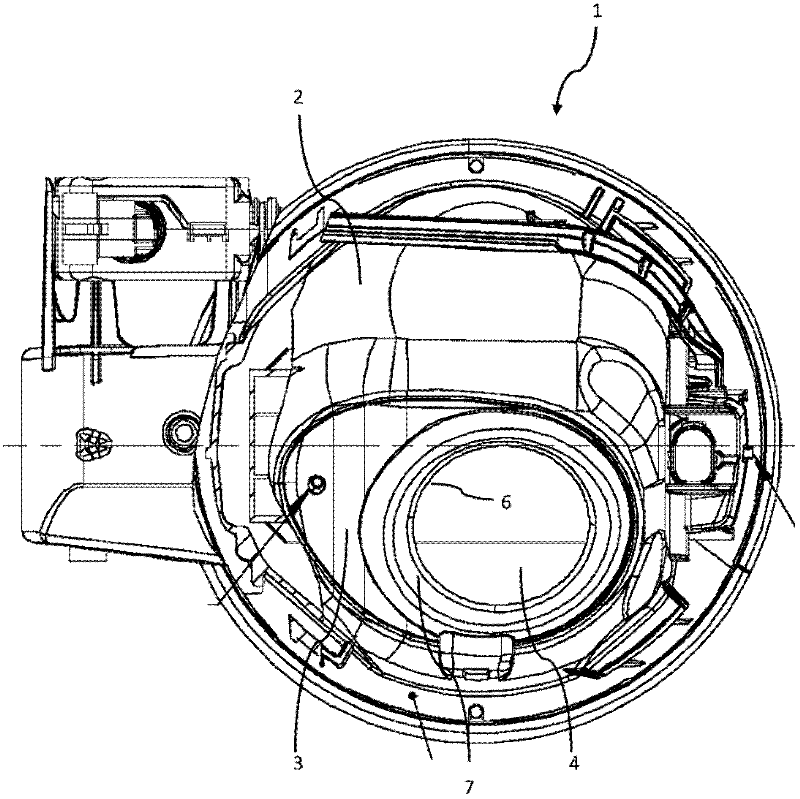

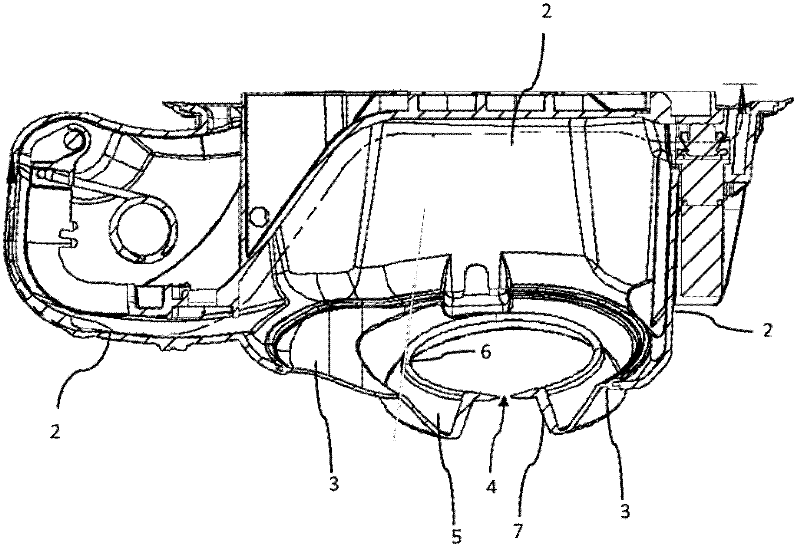

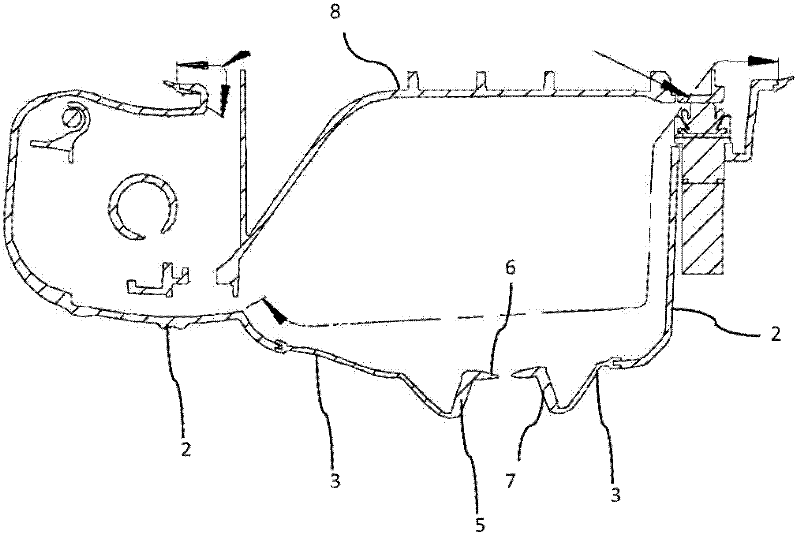

[0027] Figures 1 to 3 The tank cover module 1 shown in is constructed as a two-component figure 2 The upper vehicle outer side has the pot part 2 and the lower part, ie in the installed state pointing towards the vehicle inner side, has the floor section 3 . The transition zone between the bottom section 3 and the pot part 2 can be image 3 It is clearly seen in the cross-section of the . In this transition region, the pot part 2 is injection-molded on the inside and the outside by the base section 3 .

[0028] Both the can part 2 and the bottom section or bottom guard 3 can be produced by injection molding. The pot part 2 has a relatively hard and inelastic plastic material, such as polypropylene, whereas the bottom section 3 is provided with a relatively soft and elastically deformable plastic material, preferably EPDM (ethylene propylene diene rubber). The outer cup part 2 and the base section 3 together form the tank body 1 of the fuel tank cover module. In addition...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average roughness | aaaaa | aaaaa |

| Average roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com