Automatic weld length counting module for electric welding machine

A welding seam length and statistics module technology, which is applied in the field of automatic welding seam length statistics module for electric welding machines, can solve the problems of inconvenient operation, large waste of resources, and inability to automatically count weld lengths, etc., and achieves convenient wiring, low investment cost, Effect of Avoiding Out-of-Position Welding Problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

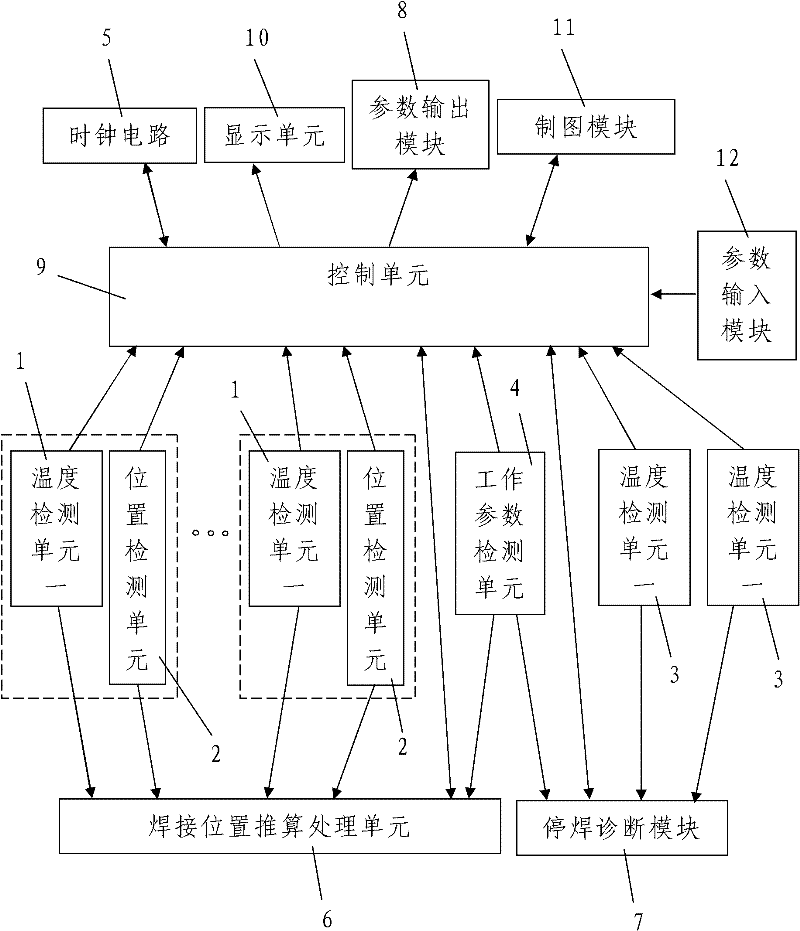

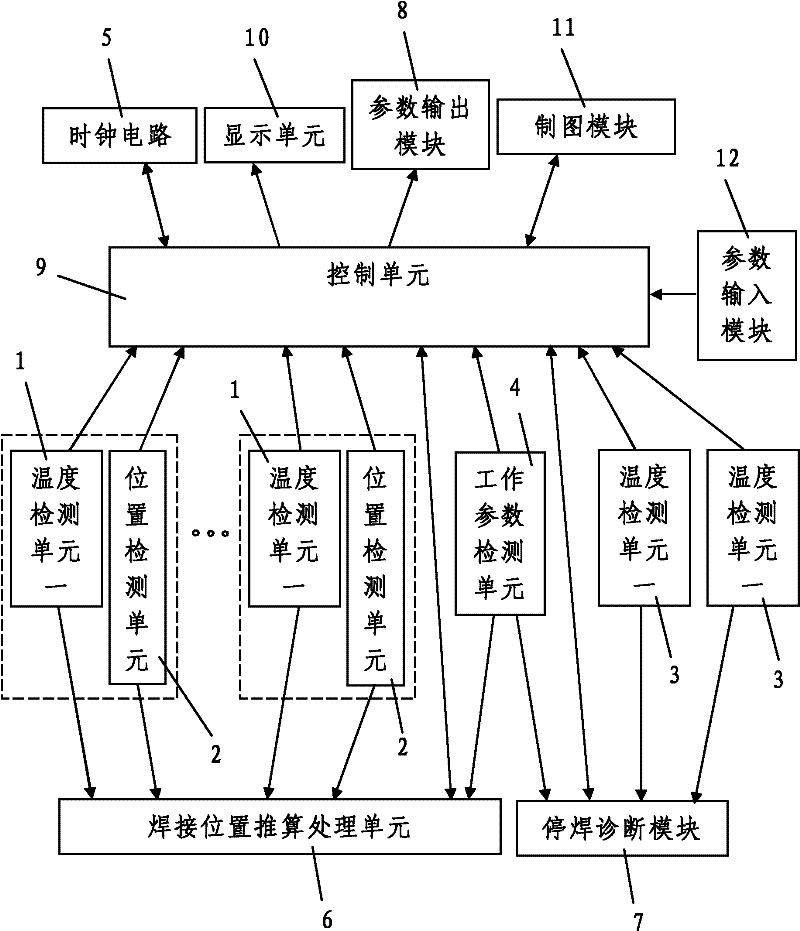

[0027] Such as figure 1 As shown, the present invention includes a plurality of temperature detection units-1 arranged side by side on one side of the welding area, a plurality of position detection units respectively arranged on each temperature detection unit-1 and detecting the position of each temperature detection unit-1 2. Two temperature detection units 2 respectively arranged on the upper and lower sides of the end of the welding area 3. The working parameter detection unit 4 for real-time detection of the relevant working parameters of the welding machine used, the control unit 9, combined with multiple position detection units 2 The detected position information performs internal analysis and processing on the detected information of multiple temperature detection units 1 and working parameter detection unit 4, and correspondingly calculates the welding position estimation processing unit 6 of the current theoretical welding position, and the temperature detection uni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com