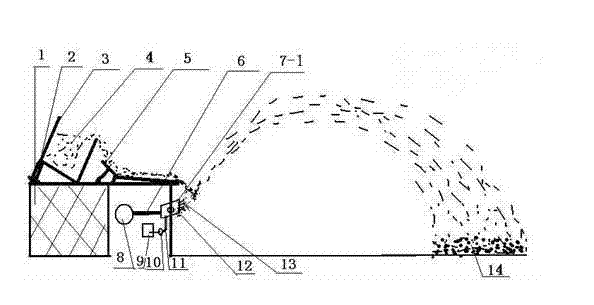

High-temperature liquid-state steel slag granulating device and process

A technology of liquid steel slag and steel slag, which is applied in the field of high-temperature liquid steel slag granulation device and granulation process, can solve the problems of narrow application range, poor uniformity, poor stability of steel slag balls, etc., and achieve high efficiency, sufficient granulation, and steel slag Fully granulated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

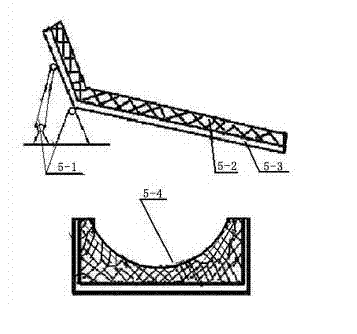

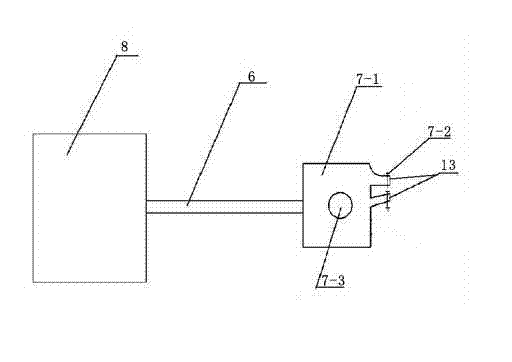

Method used

Image

Examples

Embodiment 2

[0029] The weight of liquid electric furnace steel slag is 500kg, the temperature is 1600°C, and its chemical composition (weight percentage) is as follows: CaO: 29.1%, MgO: 9.7%, SiO 2 :16.5%,Al 2 o 3 : 3.5%, FeO: 20.9%, MnO: 4.5%, free calcium oxide 6.3%, free magnesium oxide: 8.9%, other 0.6%. The steel slag flow rate is 0.1t / min, the gas pressure in the air cavity is 0.05MPa, and the air volume is 5m 3 / min; the angle between the spray panel and the horizontal direction is 55°; the angle between the second layer of nozzles and the normal line of the panel is 5°, after the steel slag is granulated according to the above process, the FeO phase in the steel slag disappears, and the content of free CaO and MgO is low. to 0.1%, while 2CaO·Fe 2 o 3 The phase increases significantly, the steel slag is granulated into balls, with a spinel structure, and the structure is stable.

[0030] The comparison of the appearance and composition of the steel slag processed by this meth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com