Reserved light unit type optical fiber composite cable

A fiber optic composite cable and optical unit technology, applied in the direction of communication cables, cables, circuits, etc., can solve the problems of power line waste, increase cable laying costs, etc., and achieve the effect of reducing laying costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

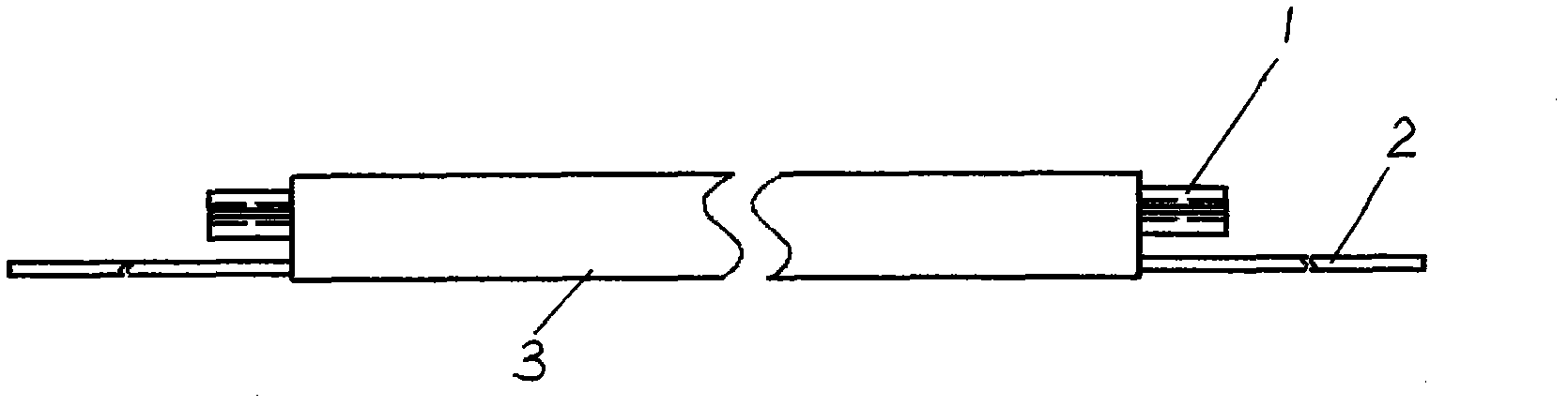

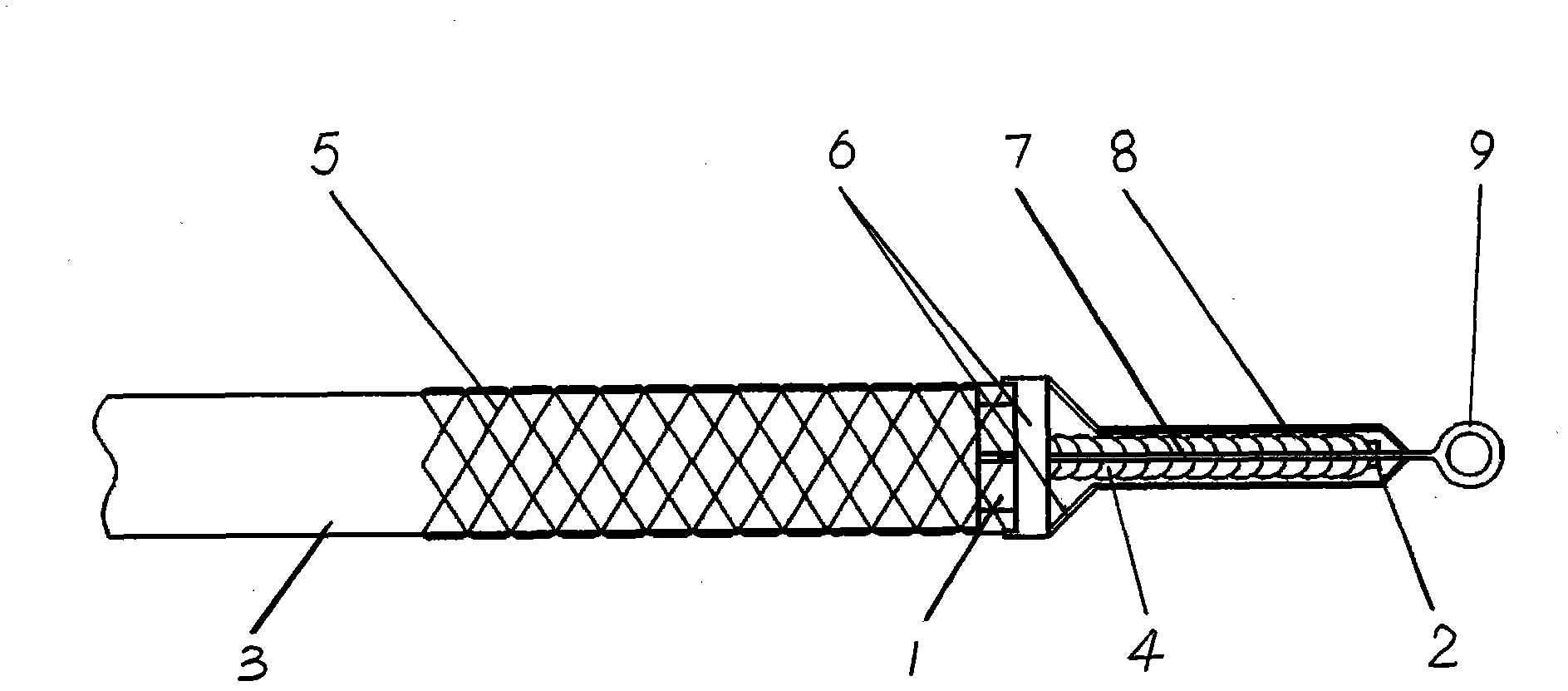

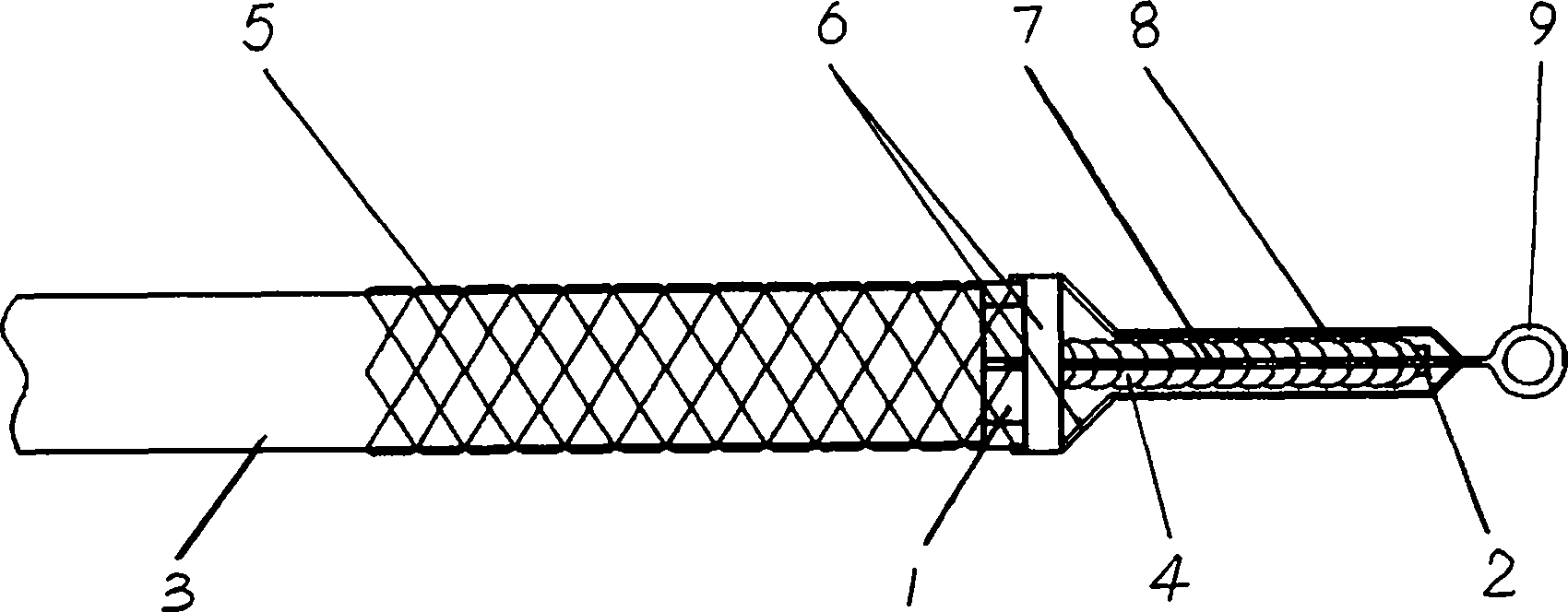

[0010] refer to figure 1 , figure 2 When making the present invention, an optical unit extension 2 about 20m longer than the power unit 1 is arranged at both ends of the cable, and a spring protective sleeve 4 is arranged on the outer surface of the optical unit extension 2, and a tight The metal mesh sleeve 5 fixed on the surface of the outer sheath 3 and the metal mesh sleeve connecting ring 6 connected with the traction rope 7, for the convenience of pulling the cable, a suspension ring 9 can be set at the tail end of the traction rope 7, around the extension section 2 of the optical unit Tensile steel wire 8 is set. In order to prevent water from entering both ends of the cable and the optical unit, the end faces of the cable and the optical unit can be sealed separately.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com