Injection molding machine having energy-saving device and inverter

An energy-saving device and injection molding machine technology, which is applied in the field of injection molding machines, can solve the problems of energy waste and slow response time, and achieve the effects of saving brake units, reliable devices, and energy saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

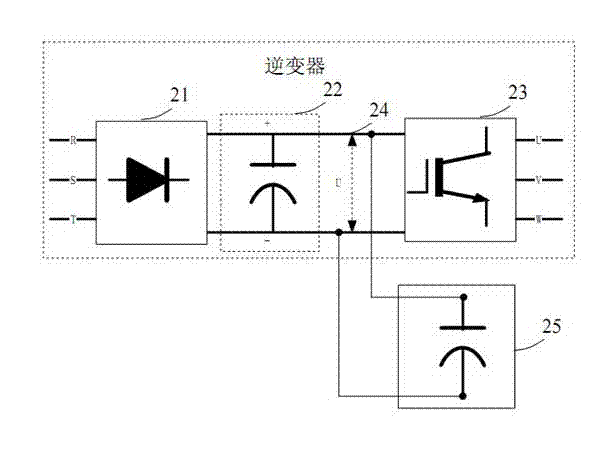

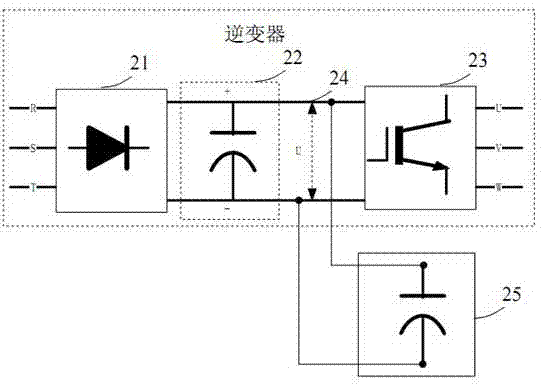

[0021] After investigation, the operating cost of the injection molding machine is mainly determined by the electricity cost of producing the product and the time required to produce the product. In order to improve production efficiency, each production link of the injection molding machine, such as sol, injection, pressure holding, mold opening and closing, and thimble, needs to be quickly braked by the motor. In addition, the braking of injection molding machines is different from that of cranes, elevators, and fans. Its characteristics are: frequent braking, but small braking inertia.

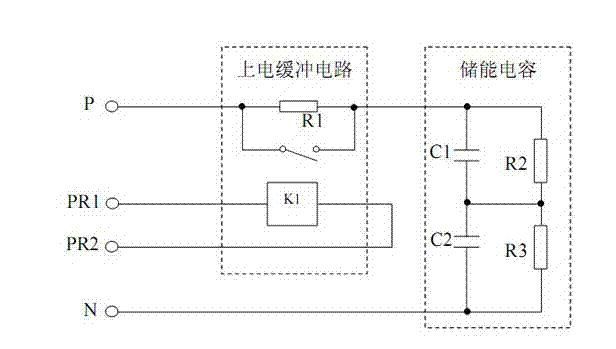

[0022] Based on the above problems, the present invention proposes a novel braking method, which can effectively avoid energy waste in the braking process and improve the quick response of braking. The invention replaces the brake unit with an energy-saving device on the DC bus, and stores the feedback energy of the mechanical inertia of the injection molding machine, which not only meets t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com