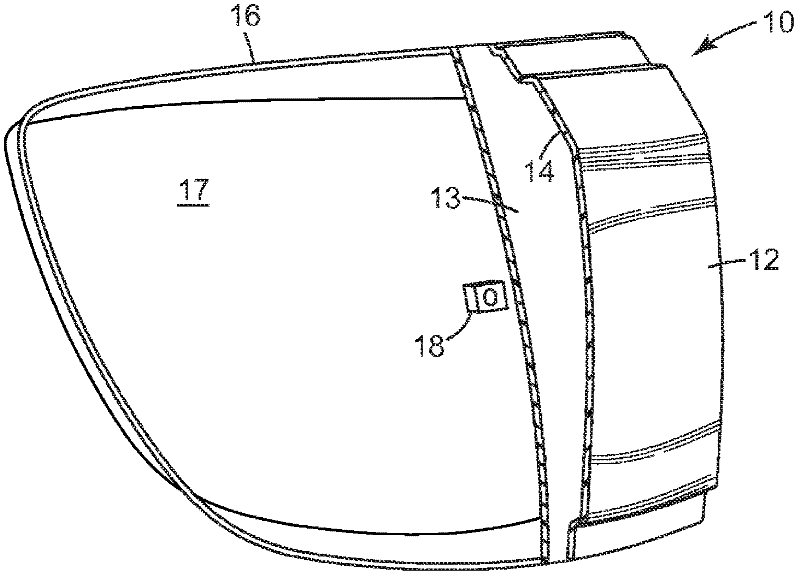

Light assembly

A technology for lamp assemblies and lighting assemblies, which is applied to optical components, vehicle parts, and parts of lighting devices, etc., and can solve the problems of difficulty in uniform illumination and inability to redirect light.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

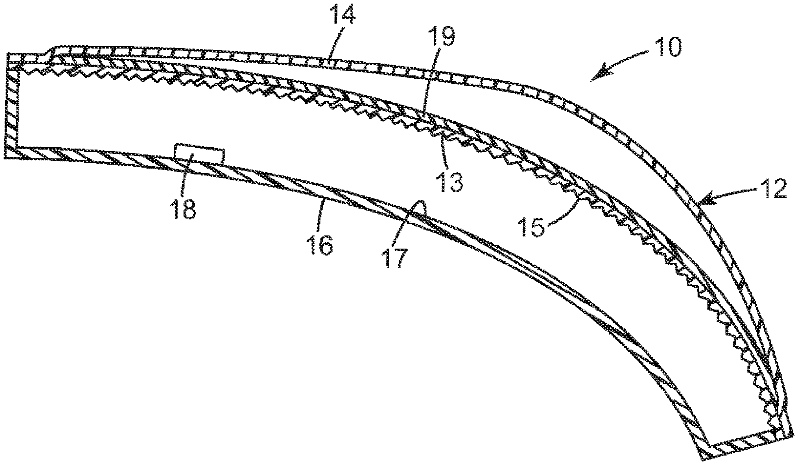

example 1

[0299] Microstructured (cube corner) polycarbonate films comprising PG cube corner elements were prepared using an extrusion process through a die made from multiple generations of replicas of a preferred geometry (PG) cube formed on a thin layer. Production of microstructured films using extrusion processes through microstructured tools is known in the art and generally described in U.S. Patent No. 5,450,235 (Smith et al.) and U.S. Patent No. 7,364,421 (Erickson et al.), which The disclosure is incorporated herein by reference. The mold used in this example is generally described in US Patent No. 7,329,012 (Smith), and its detailed construction is as follows. Use forward-sloping cubes such as those shown in Figure 11 of US Patent No. 7,329,012 (Smith). The forward-sloping PG cubes were formed on thin layers at a thickness of 0.173 mm (0.0068 inches). The spacing between the side slots is 0.104 mm (0.00408 inches). The angle of the side grooves is nominally 90 degrees, the ...

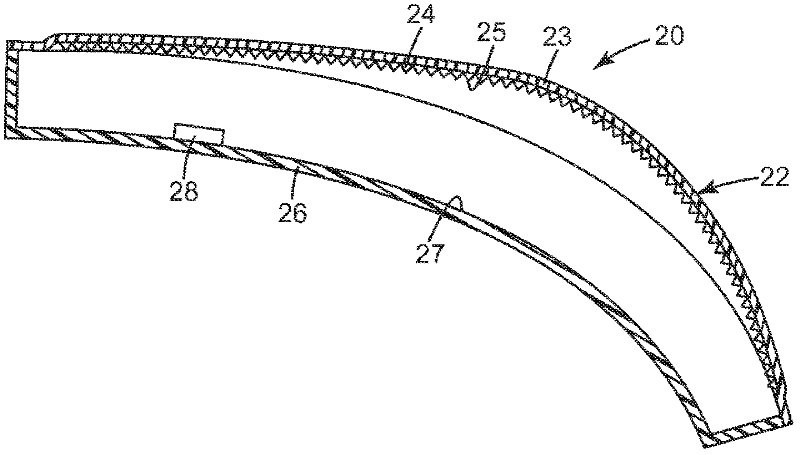

example 2

[0305] Example 2 was prepared as described in Example 1, except that the light-emitting diodes were in the sidewalls, as image 3 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com