Chemical fiber cloth napping liner polrvinyl chloride gloves and processing method

A polyvinyl chloride and processing method technology, applied in gloves, clothing, clothing, etc., can solve the problems of hard gloves, shortage of raw materials, and high prices, and achieve the effects of good heat retention, easy access to materials, and low cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

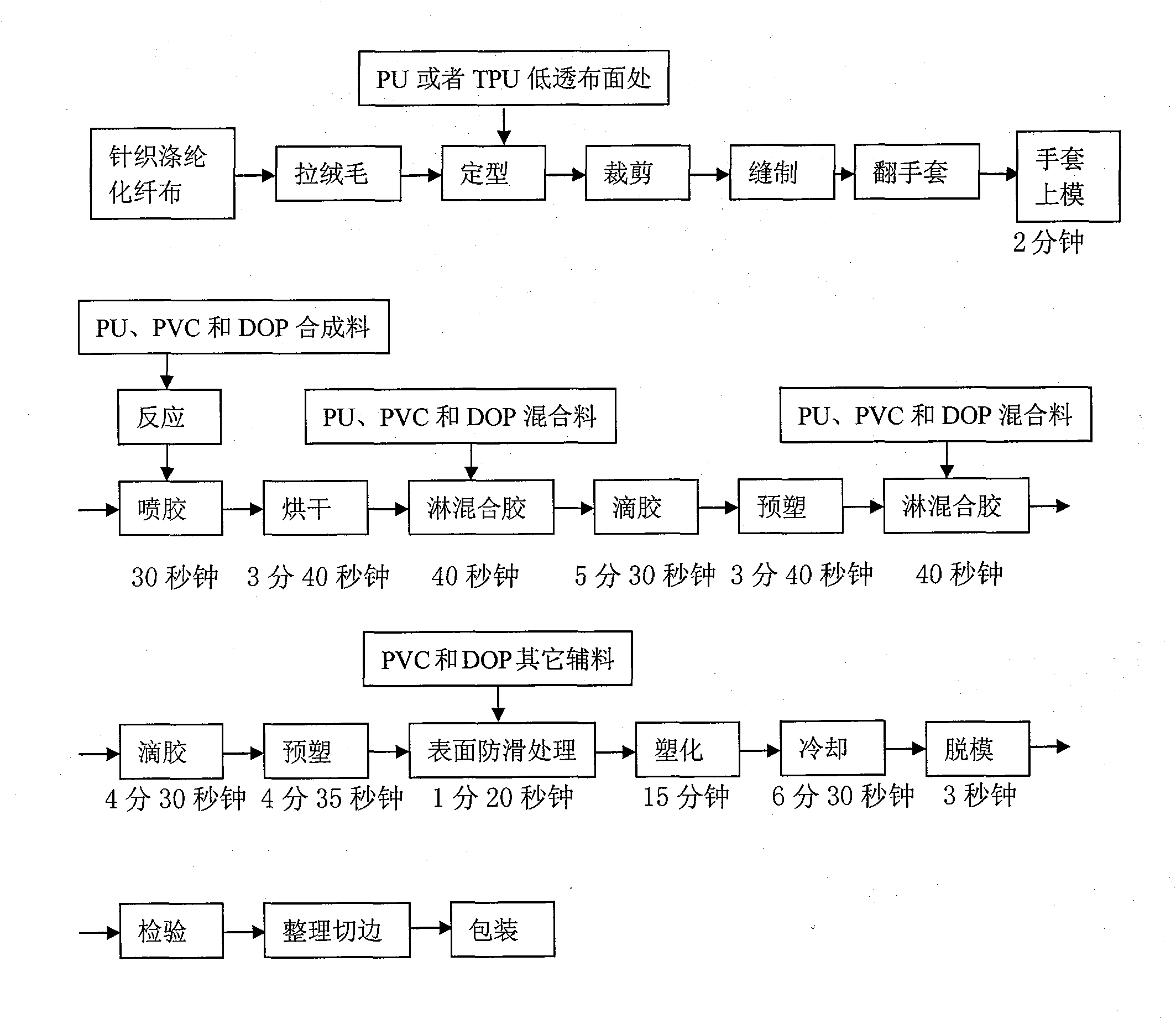

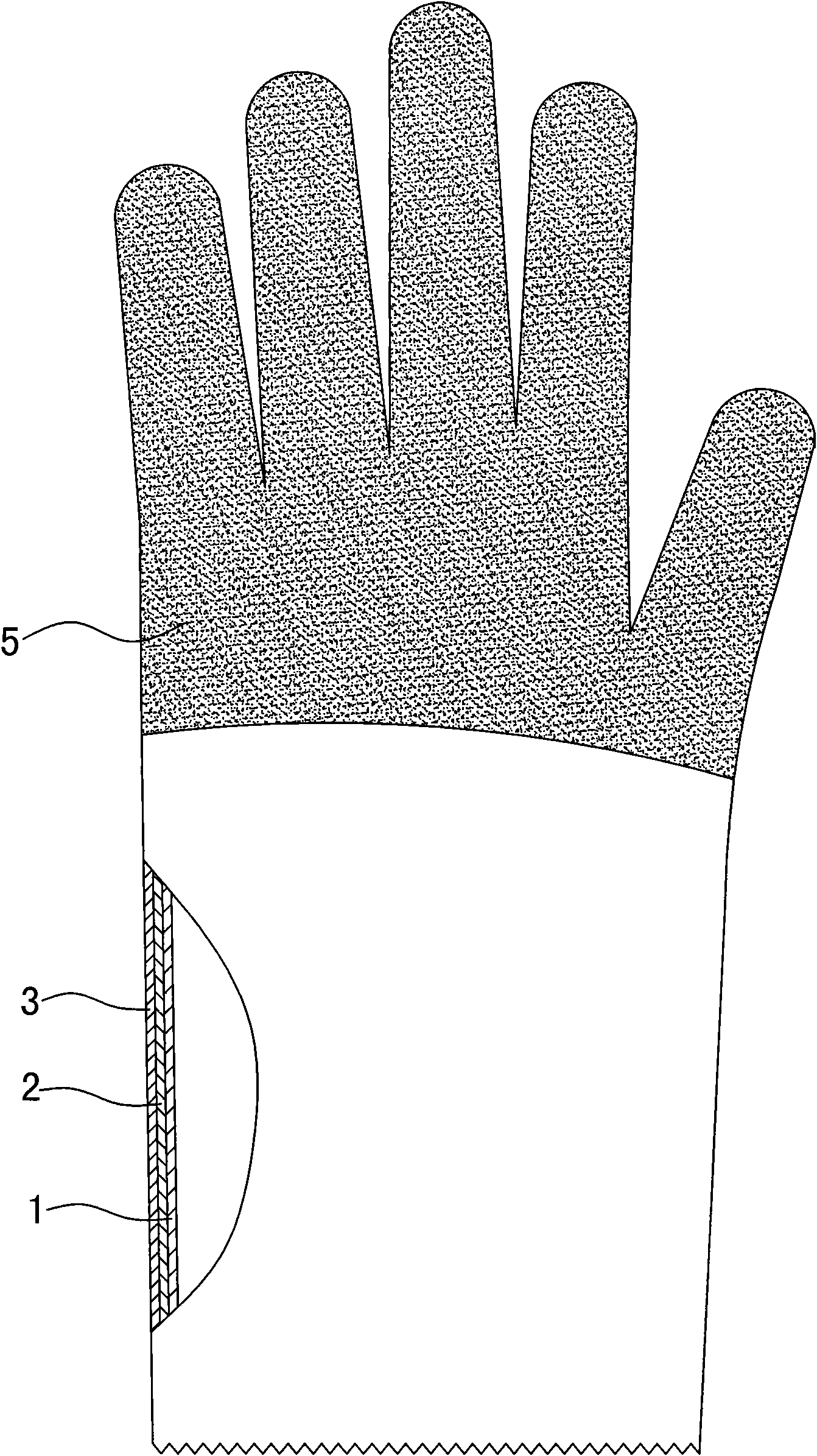

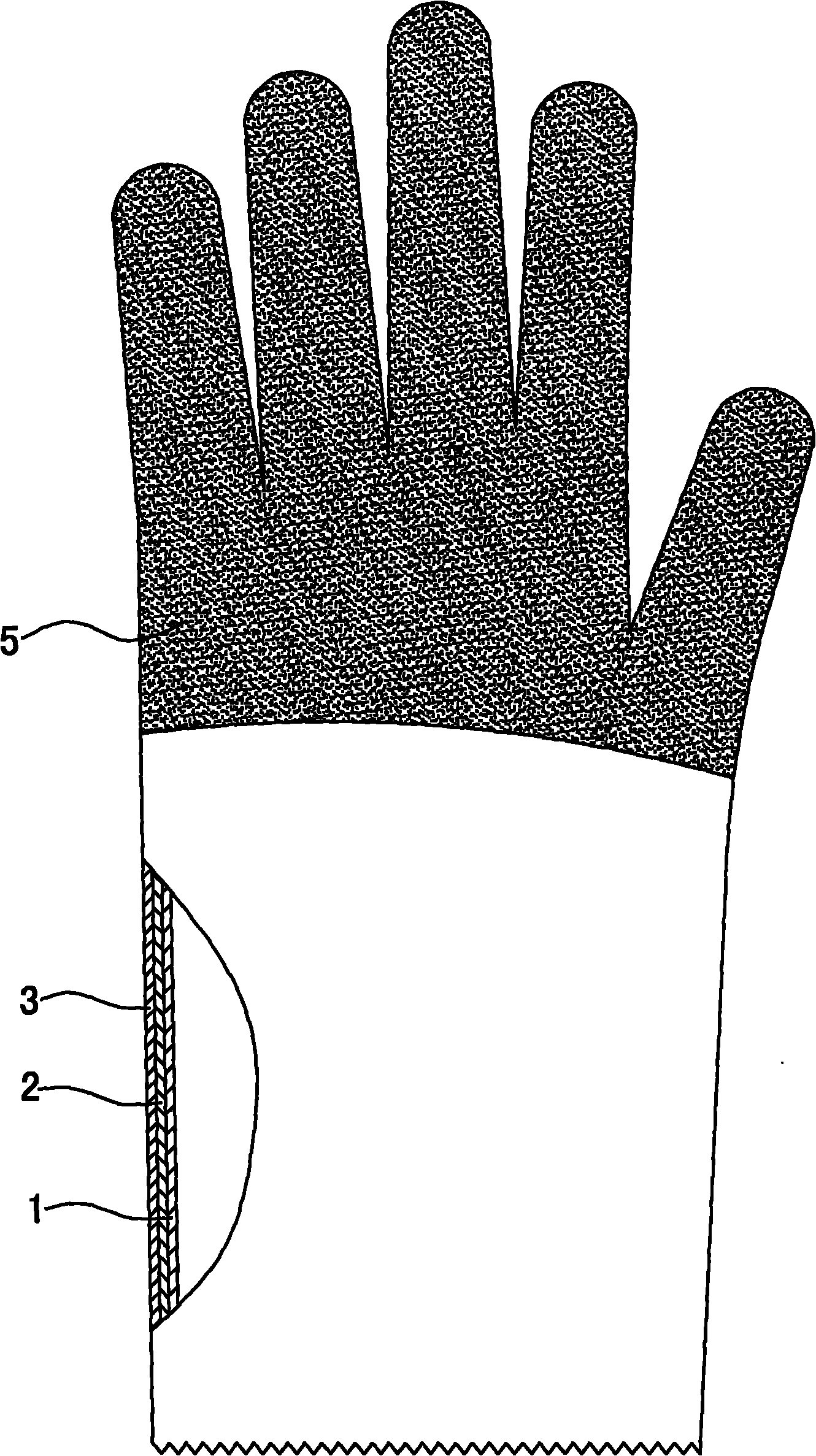

[0019] The invention discloses a chemical fiber cloth fleece lined polyvinyl chloride glove and a processing method, such as figure 1 , figure 2 As shown, it includes a knitted polyester chemical fiber brushed cloth layer 1, a diaphragm layer 2 on the surface of the knitted polyester chemical fiber brushed cloth layer, and a modified polyvinyl chloride surface layer 3 outside the diaphragm layer. Knitted polyester chemical fiber cloth is used to make the inner lining of gloves by brushing one side of it. The knitted polyester chemical fiber cloth is easy to obtain, low in cost, good in warmth retention, better in hand feeling and durable. Because the knitted polyester chemical fiber cloth is used as the inner lining of gloves , the polyvinyl chloride material will infiltrate when spraying glue, so a diaphragm layer is sprayed on the surface of the inner lining layer of the knitted polyester chemical fiber cloth. With the diaphragm layer, the modified polyvinyl chloride (modif...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap