Low-pressure cast aluminum-alloy wheel-casting sequential-solidification temperature-field compensating method

A sequential solidification and low-pressure casting technology, which is applied in the field of automotive aluminum alloy wheel casting, can solve the problems of many casting defects, rising manufacturing costs, and low casting pass rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0007] specific implementation

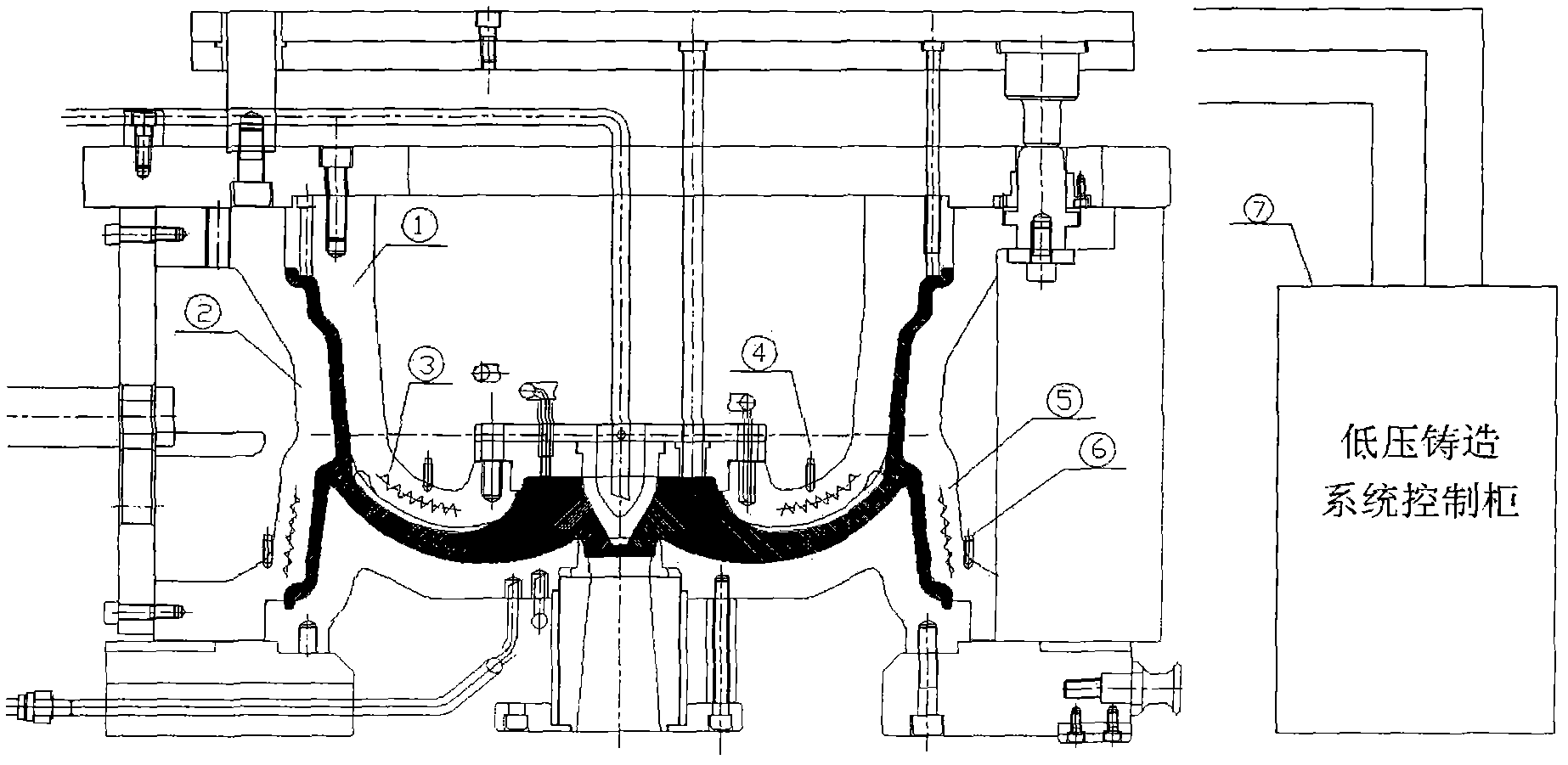

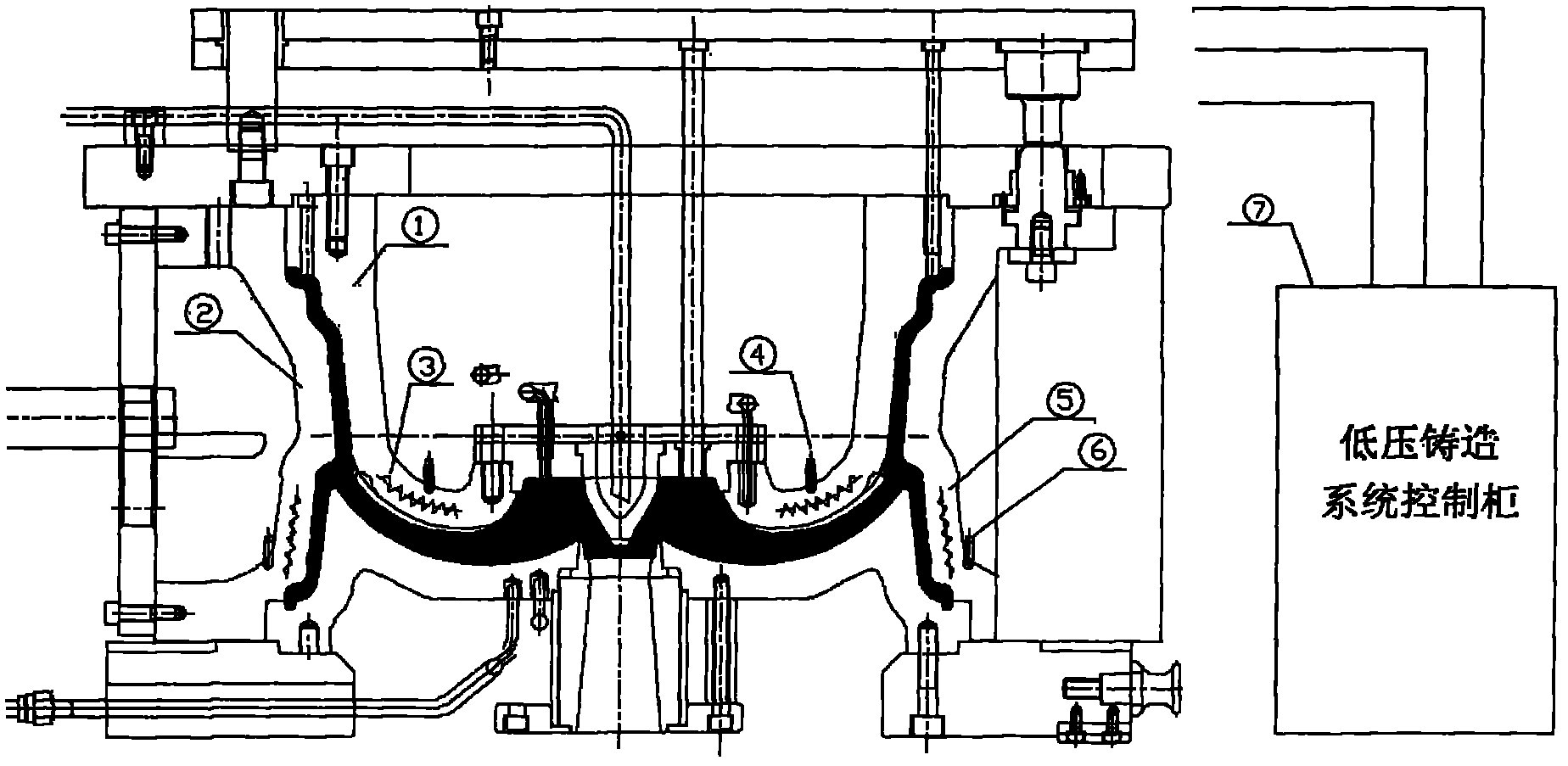

[0008] Before the development of the mold, the casting simulation solidification is carried out to find out the area where the mold needs to be compensated for the temperature field. According to the casting simulation solidification results, this area is at the position of the top mold 1 and the side mold 2, and the heating resistance wire is installed at the top mold 1. 3. Top mold temperature measuring thermocouple 4, install heating resistance wire 5, side mold temperature measuring thermocouple 6 at side mold 2, and heat resistance wire 3, heating resistance wire 5 and top mold temperature measuring thermocouple 4, side mold The mold temperature measuring thermocouple 6 is connected with the control cabinet 7 of the low-pressure casting system, and the mold temperature is set according to the technological requirements of the casting process. When the mold temperature reaches the technological requirements, the heating resistance wire stops...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com