Fixture for manually loading core for pipe belt type aluminum composite radiator

A tube-belt type, radiator technology, applied in the direction of manufacturing tools, workpiece clamping devices, etc., can solve the problems of high production cost, assembly, small quantity, etc., and achieve high core loading efficiency, reduced labor intensity, and rapid core loading. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

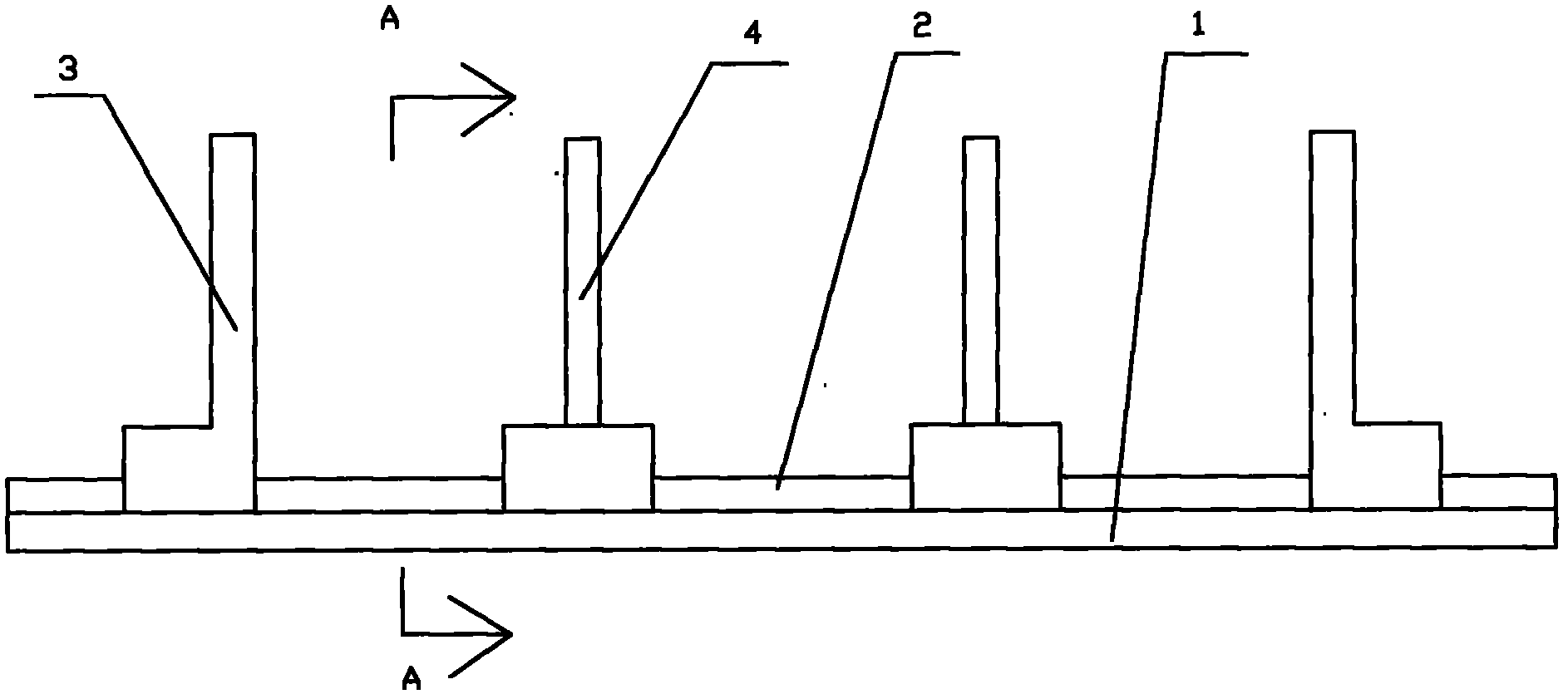

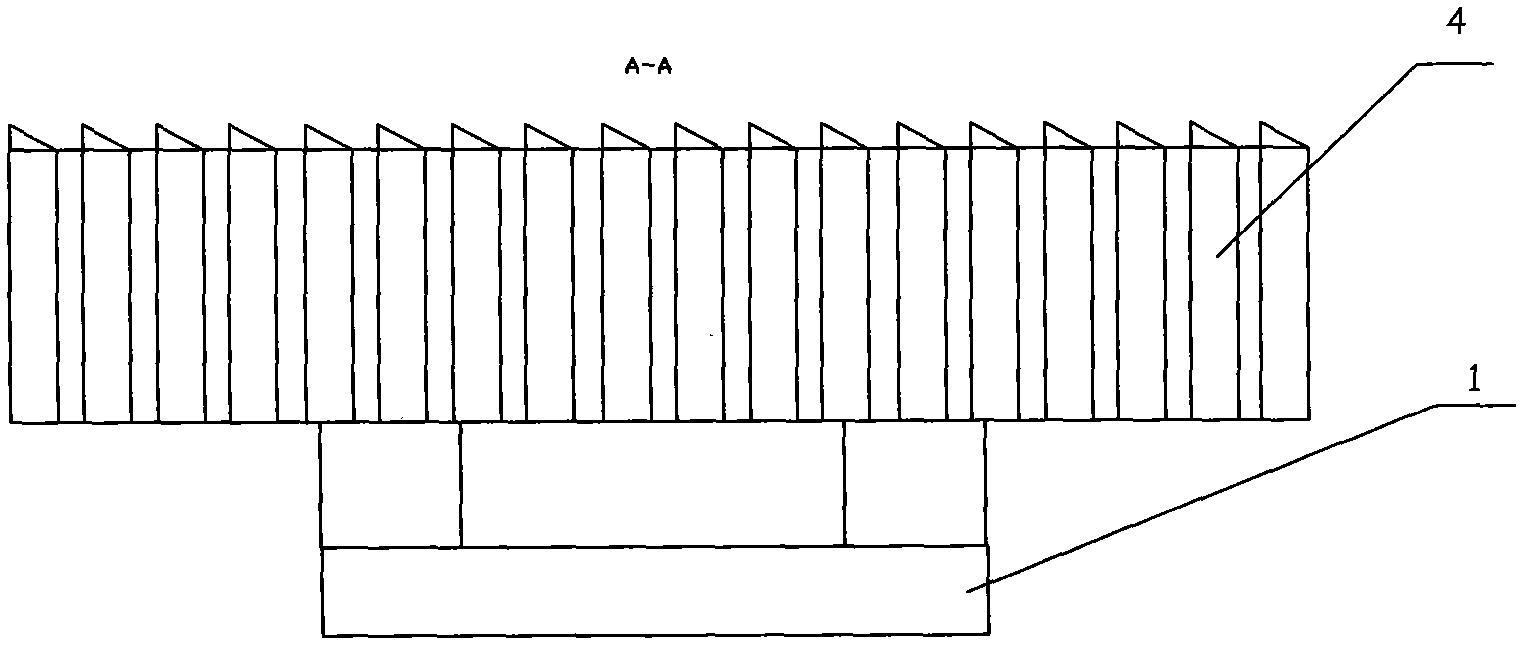

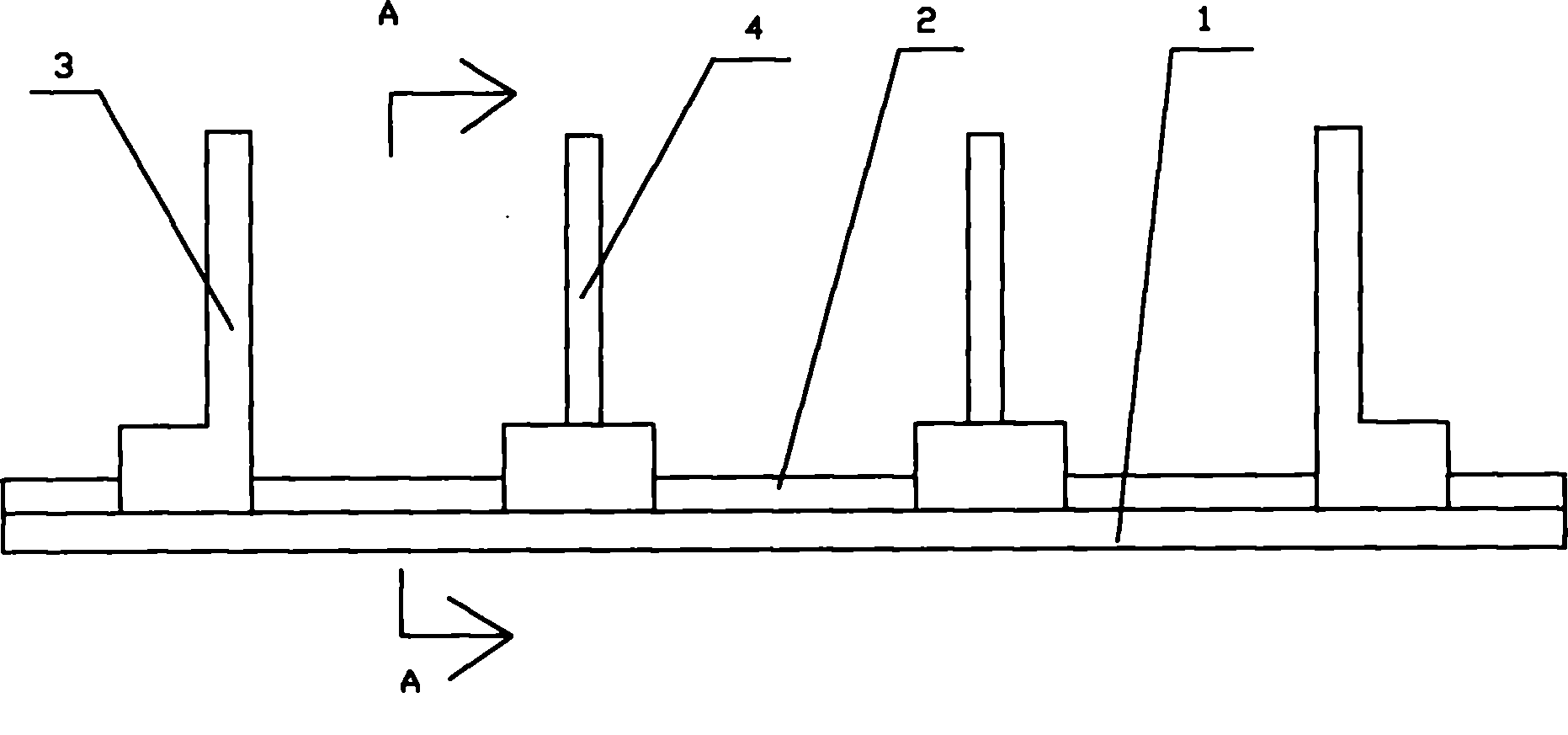

[0012] A pipe-belt-type aluminum-plastic radiator manual core assembly fixture, including a base plate 1, a linear guide rail 2 is provided on the base plate 1, a baffle plate 3 is vertically fixed at both ends of the linear guide rail 2, and the two baffle plates 3 A pair of comb-tooth plates 4 are arranged vertically between them. Each tooth end surface of the comb-tooth plates 4 is inclined. The plate 4 is connected to the linear guide 2 by means of pulleys.

[0013] During manual operation, wipe a pair of aluminum-plastic radiator water pipes horizontally across the comb plate 4. Since the end face of each tooth of the comb plate 4 is set at a certain angle, the water pipe can be spread out quickly when installing the water pipe. , and quickly enter the spacing hole of the comb plate 4, and then push a pair of comb plate 4 to use the fixed baffle plate 3 to arrange the radiator water pipes along the surface of the comb plate 4.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com