Process method for preparing polyisobutene and polymerization device

A process method and technology for polyisobutene, applied in the field of preparing polyisobutene by slurry method, can solve the problems of short residence time, high micro-mixing degree, difficult-to-polymerize isobutene polymerization process, etc., so as to reduce operating costs, improve mixing efficiency, strengthen The effect of the polymerization process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

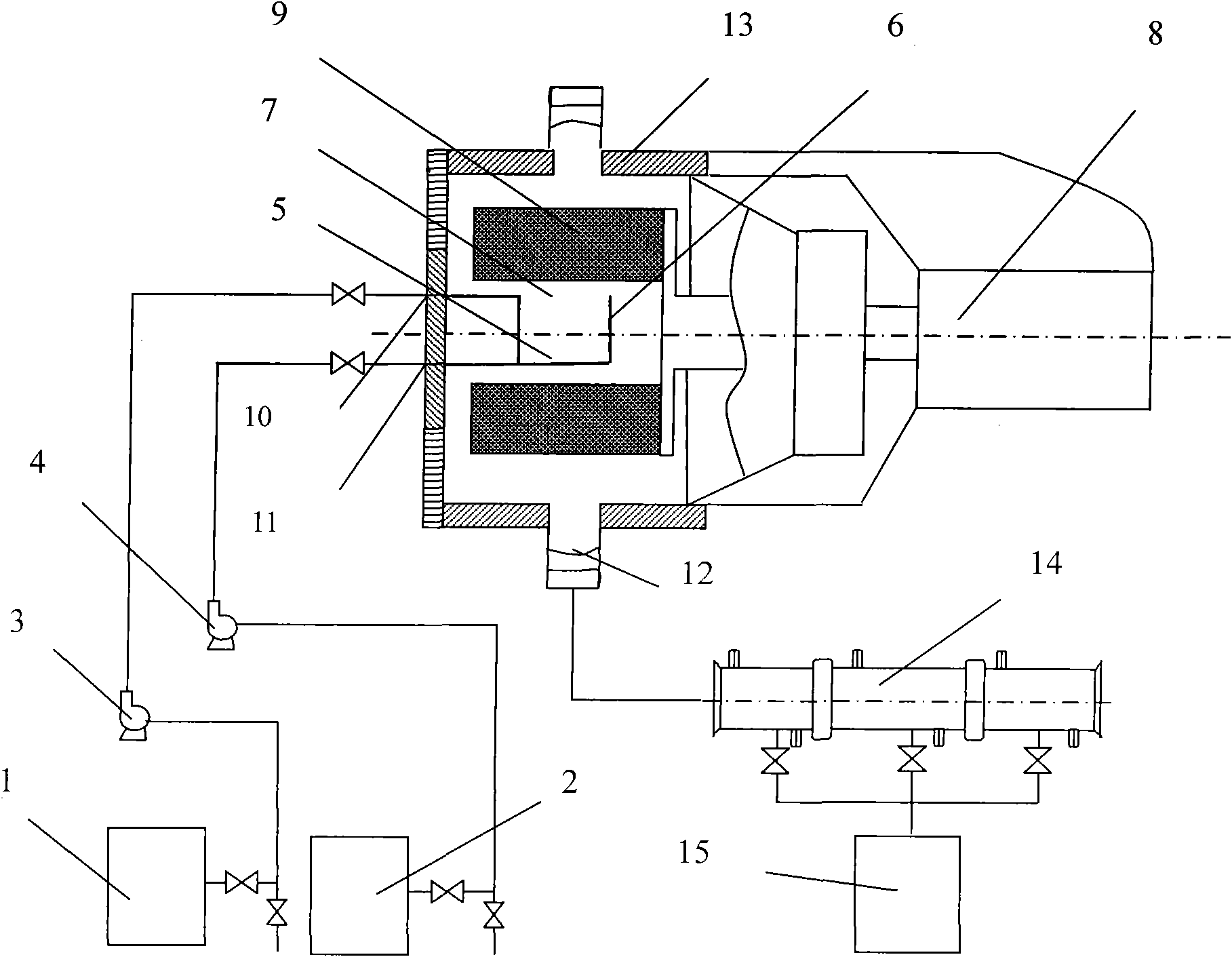

[0030] use figure 1 In the device shown, the high gravity reactor is a rotating packed bed reactor.

[0031] Add 4000ml of the mixture of isobutylene monomer and dichloromethane into storage tank 1, the monomer concentration is 2.0mol / L, and the dichloromethane and AlCl 3 Add 900ml of the mixed solution B into storage tank 2, where the initiator is 0.25 mol / L. When the materials in storage tank 1 and storage tank 2 are cooled to about -25°C, respectively, the two are separated by a double plunger metering pump. The strands are fed into the premixing tube in the high-gravity rotating packed bed reactor at a volume ratio of 10:1, and the mixture is sprayed into the rotor packing layer by the liquid distributor to initiate preliminary polymerization, and the reaction liquid enters through the liquid outlet of the rotating packed bed The reaction was continued for 1 min in a tubular reactor with an aspect ratio of 15:1. The rotor speed of the supergravity rotating packed bed reactor...

Embodiment 2

[0033] The process and steps are the same as in Example 1, the monomer concentration is 1.5 mol / L, the initiator concentration is 0.15 mol / L, the material volume ratio is 5:1, and the number average molecular weight of the obtained polyisobutylene product is M n It is 1300, the molecular weight distribution index is 1.95, the yield is 94%, and the content of the alpha-double bond at the molecular end is 90%.

[0034] Implementation column 3

[0035] The process flow and steps are the same as in Example 1. The monomer concentration is 1.5 mol / L, the initiator concentration is 0.35 mol / L, and the material volume ratio is 15:1. The reaction in the tubular reactor is 10s. The gravity level is 500g. The number average molecular weight of the obtained polyisobutylene product M n The molecular weight distribution index is 1400, the molecular weight distribution index is 2.02, the yield is 90%, and the alpha-double bond content at the molecular end is 91%.

[0036] Implementation column 4

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com