Internal combustion engine

An internal combustion engine and fuel technology, which is applied to combustion engines, mechanical equipment, engine components, etc., can solve the problems of unstable combustion, incomplete air flow, and difference in mixture concentration, so as to improve fuel economy, improve combustion stability, The effect of reducing pump air loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

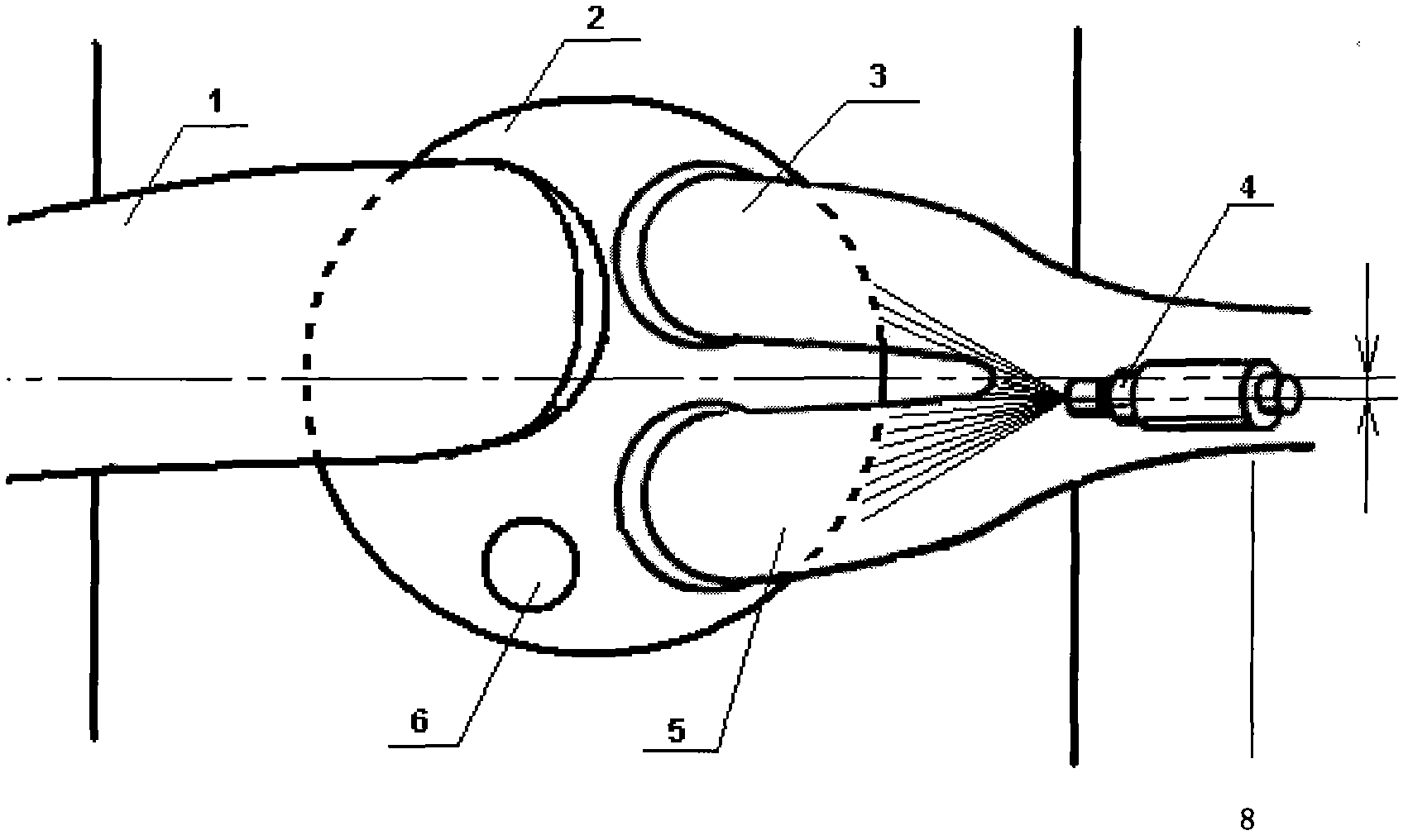

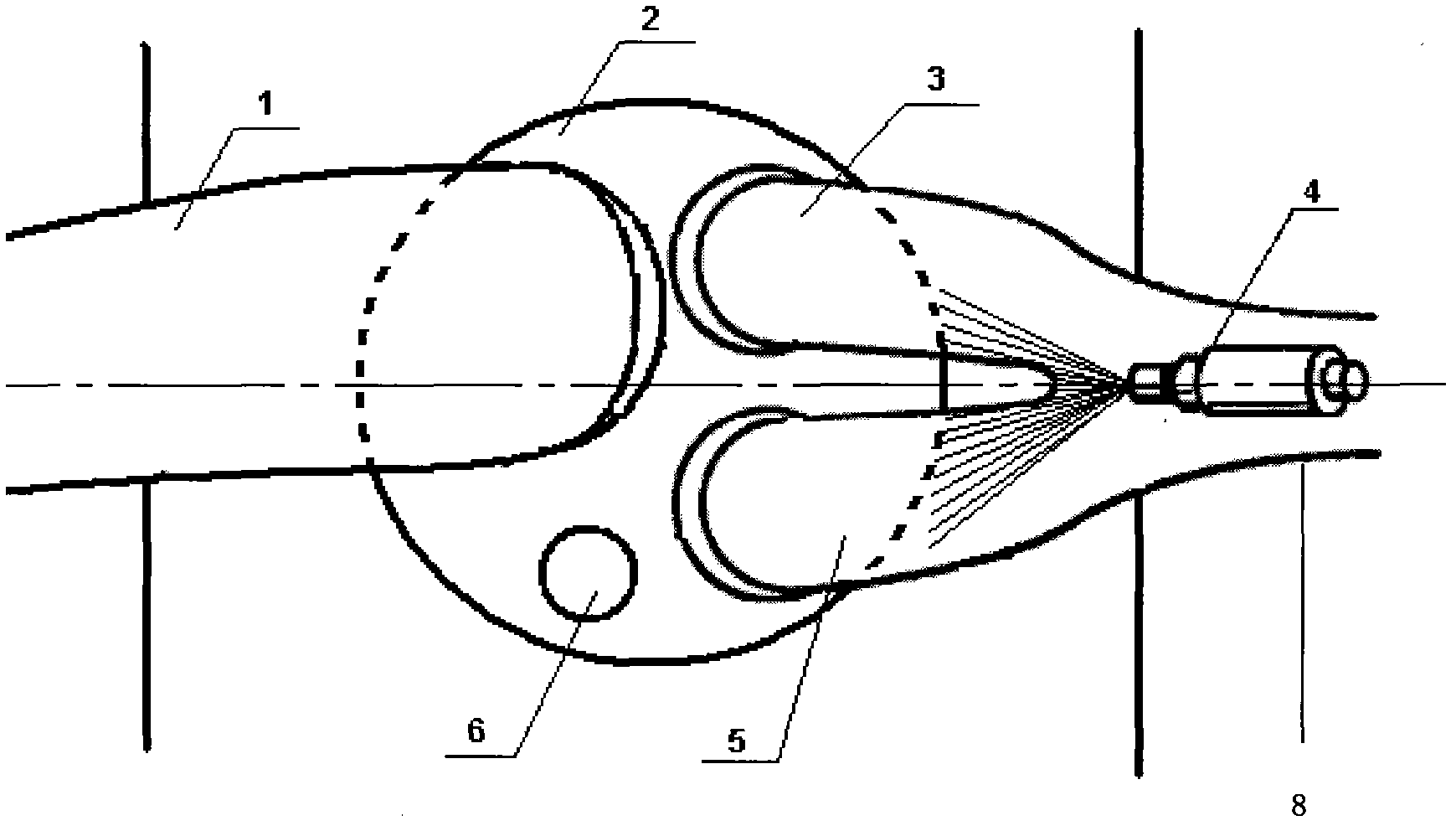

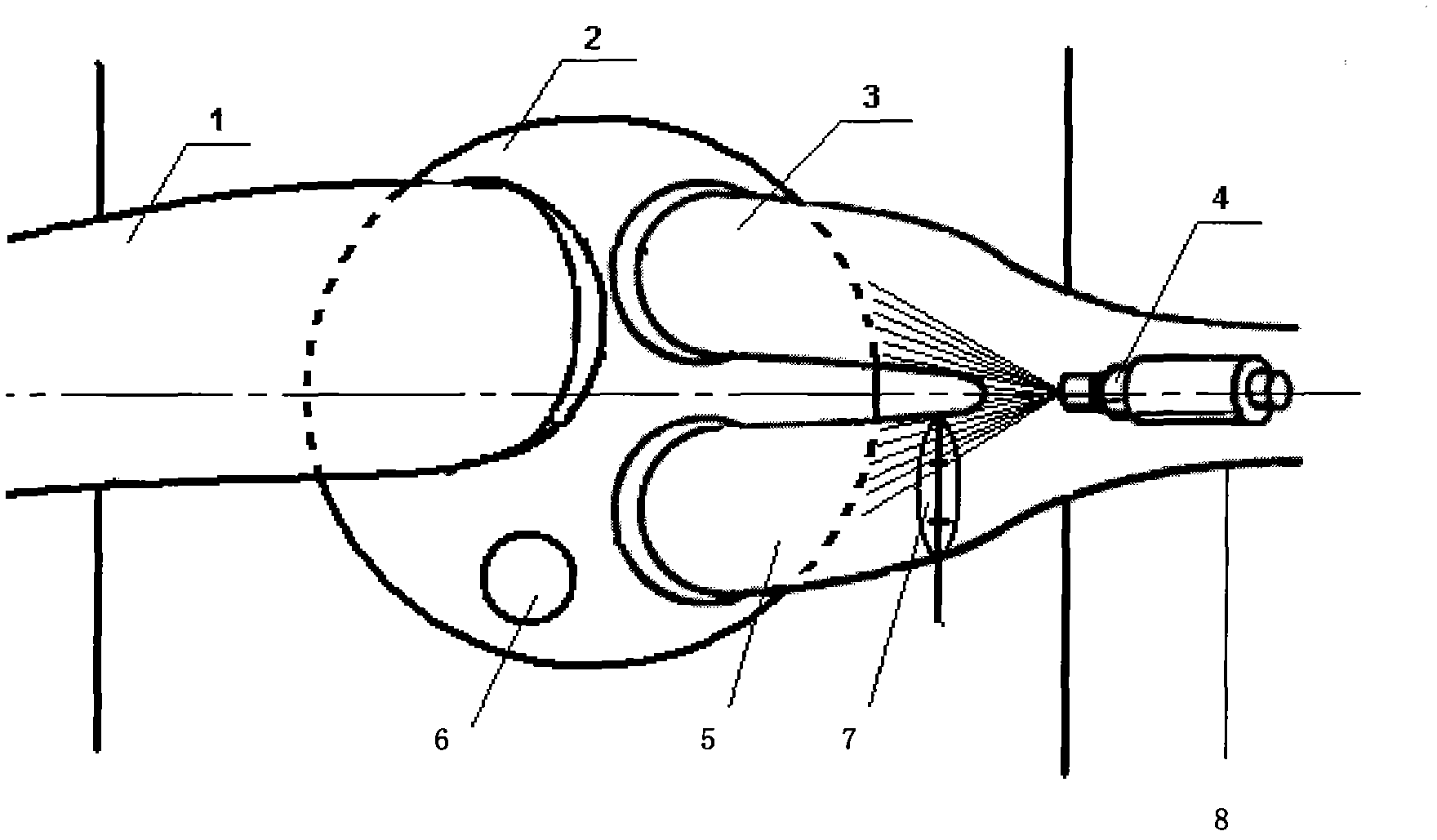

[0022] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the internal combustion engine proposed in accordance with the present invention will be described in detail below with reference to the drawings and preferred embodiments.

[0023] In the internal combustion engine of the preferred embodiment of the present invention, each cylinder includes: two intake passages communicating with the combustion chamber of the cylinder, an exhaust passage communicating with the combustion chamber of the cylinder, injecting fuel into the intake passage and mixing it with air In the fuel injector that forms the combustible mixture and the spark plug used for ignition, the fuel concentration of the combustible mixture in the intake port near the spark plug side is higher than the fuel concentration of the combustible mixture in the other intake port...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com