Face cleaning foam and preparation method thereof

A cleansing foam and surfactant technology, applied in the field of cosmetics, can solve problems such as limited cleaning effect, and achieve the effect of rich foaming power, low irritation, and rich foam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

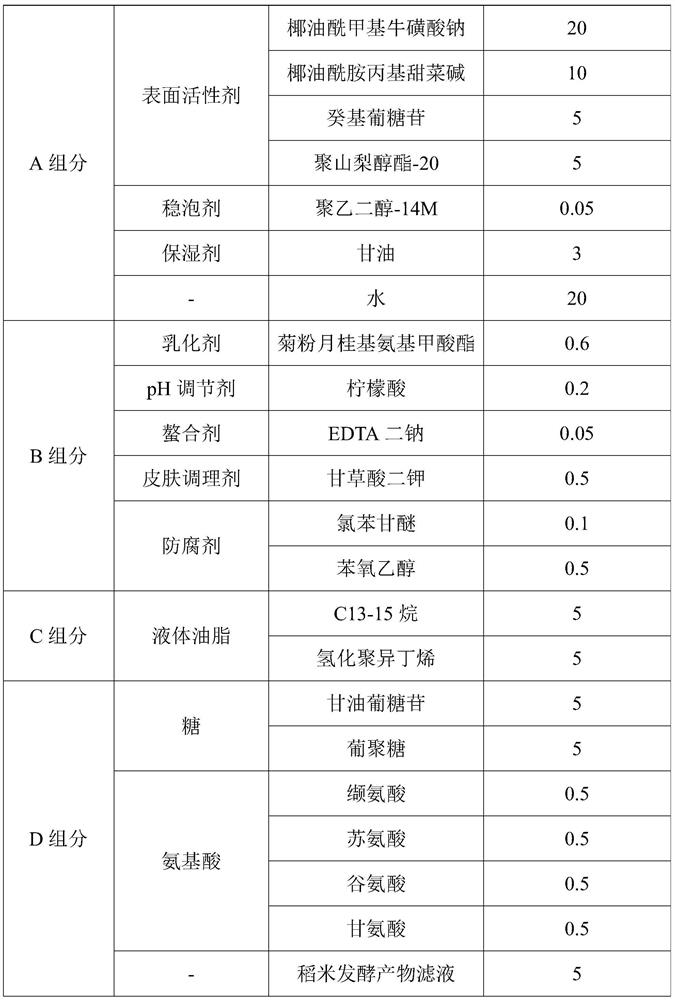

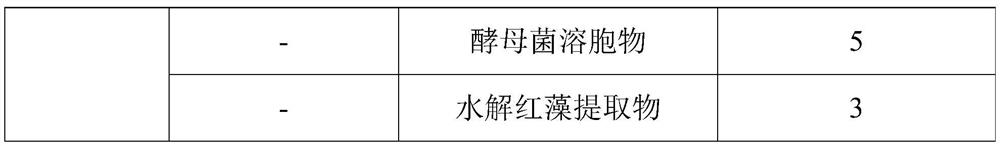

[0080] This embodiment provides a cleansing foam, and the preparation raw materials of the cleansing foam include the following components in parts by weight:

[0081]

[0082]

[0083]

[0084] The preparation method of the cleansing foam comprises the following steps:

[0085](1) A component is added to the emulsifying pot, stirring is started at 50 rpm, the temperature is raised to 90 ℃ to dissolve, and the temperature is kept for 10 min to obtain the pretreated component A; the C component is added to the oil phase pot, and the stirring is started at 800 rpm, and the temperature is raised to 85 ℃. , keep stirring for 5min to obtain the C component after pretreatment;

[0086] (2) add B component to the A component after the pretreatment, open and stir 20rpm, be warming up to 87 ℃ of dissolving, vacuumize-0.04MPa, keep stirring for 15min, obtain the first mixture;

[0087] (3) Mix the first mixture with the pretreated component C, evacuate -0.04MPa, 2500rpm, 90 ℃ ...

Embodiment 2

[0090] This embodiment provides a cleansing foam, and the preparation raw materials of the cleansing foam include the following components in parts by weight:

[0091]

[0092]

[0093] The preparation method of the cleansing foam comprises the following steps:

[0094] (1) A component is added to the emulsifying pot, and stirring is started at 60 rpm, and the temperature is raised to 95 ℃ to dissolve, and the temperature is kept for 12 min to obtain the pretreated component A; , keep stirring for 4min to obtain the C component after pretreatment;

[0095] (2) add B component to the A component after the pretreatment, open and stir 15rpm, be warming up to 90 ℃ of dissolving, vacuumize-0.05MPa, heat preservation and stirring 13min, obtain the first mixture;

[0096] (3) Mix the first mixture with the pretreated component C, evacuate -0.05MPa, 2200rpm, homogenize at 88°C for 15min, keep the vacuum unchanged after the high-speed homogenization is completed, reduce the rota...

Embodiment 3

[0099] This embodiment provides a cleansing foam, and the preparation raw materials of the cleansing foam include the following components in parts by weight:

[0100]

[0101]

[0102] The preparation method of the cleansing foam comprises the following steps:

[0103] (1) A component is added to the emulsifying pot, and stirring is started at 60 rpm, and the temperature is raised to 87° C. to dissolve, and the temperature is kept for 9 min to obtain the pretreated A component; , keep stirring for 6min to obtain the C component after pretreatment;

[0104] (2) in the A component after the pretreatment, add the B component, open and stir 25rpm, be warming up to 88 ℃ of dissolving, vacuumize-0.03MPa, keep stirring for 17min, obtain the first mixture;

[0105] (3) Mix the first mixture with the pretreated C component, vacuumize-0.03MPa, 2300rpm, 86 ℃ of homogenization for 25min, keep the vacuum unchanged after the high-speed homogenization is completed, reduce the rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com