Combined pressure atomizing nozzle

An atomizing nozzle and combined technology, which is applied in the field of combined pressure atomizing nozzles, can solve the problems of small fuel pulse, not suitable for gas turbines, and inability to realize premixing, etc., so as to ensure uniformity and prevent violent formation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

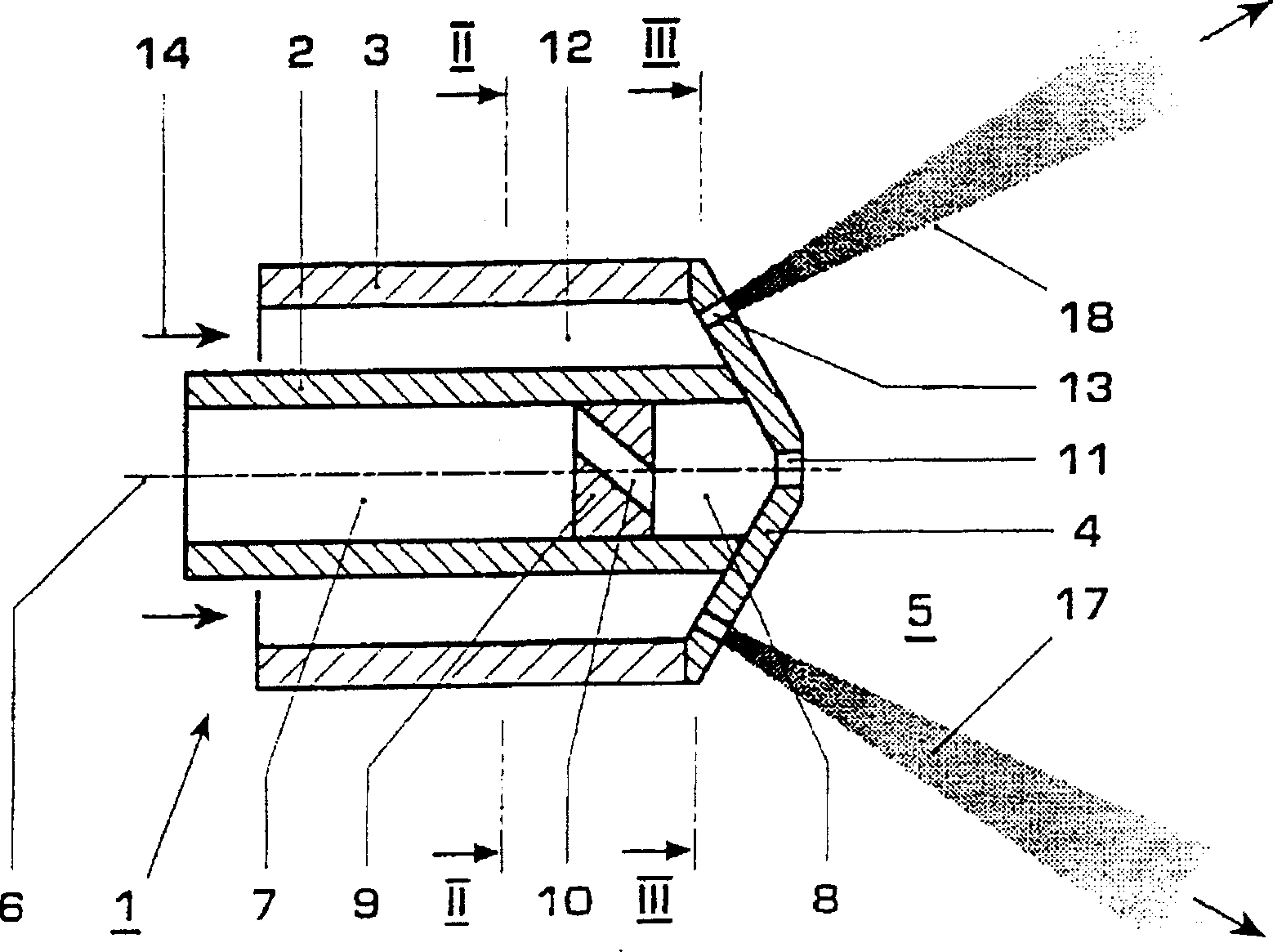

[0030] Only some elements important for understanding the invention are drawn here. For example, the combustor of the gas turbine housing the pressure atomizing nozzles is not shown. The flow direction of the working medium is indicated by arrows.

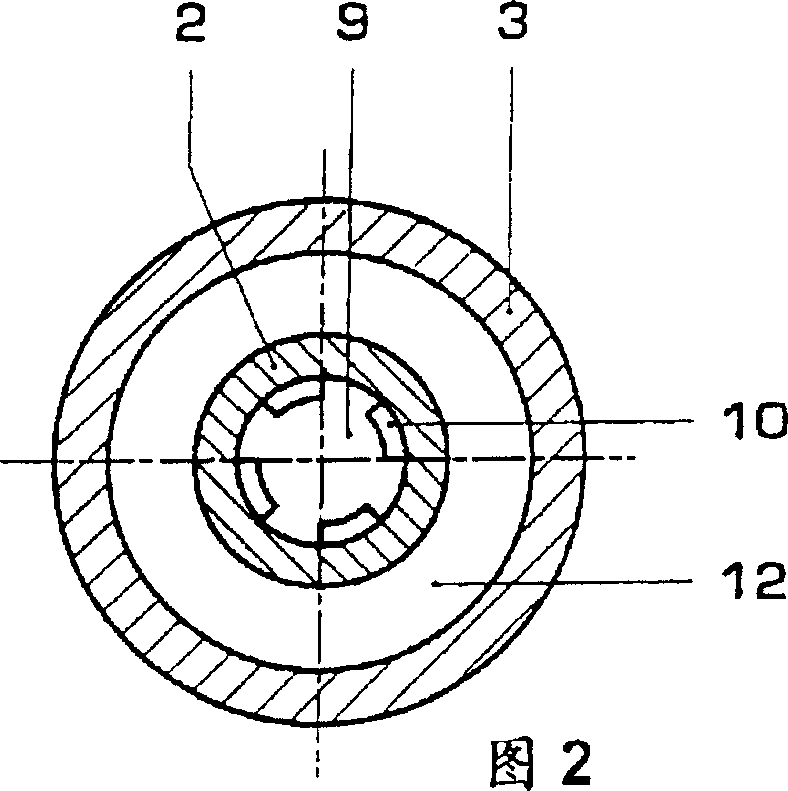

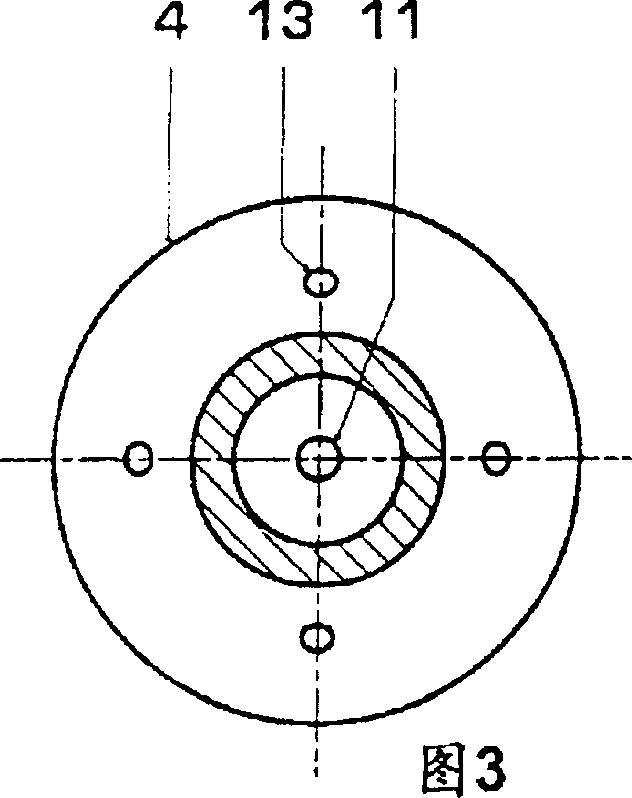

[0031] Referring now to the drawings, in all the drawings the same or equivalent parts are given the same reference numerals. The gas turbine combustor (not shown) housing the above-mentioned pressure atomizer is designed, for example, as a double-cone combustor, as disclosed in patent EP-A2-0321809. Of course, in principle, this pressure atomizing nozzle is also suitable for burners of other gas turbines, thus also suitable for example, by the disclosed burner of patent EP-A2-0 704 657, and by a mixing section adjoining A burner consisting of a vortex generator. The pressure atomizing nozzle has a nozzle body 1 with two pipe parts 2 , 3 arranged concentrically to one another, which are separated downstream from an external spac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com