Lighting device for alignment and exposure device having the same

A technology of lighting device and control device, which is applied in the direction of photographic plate-making process exposure device, micro-lithography exposure equipment, patterned surface photo-plate-making process, etc., and can solve the problems of accurate imaging and inability to align mark imaging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

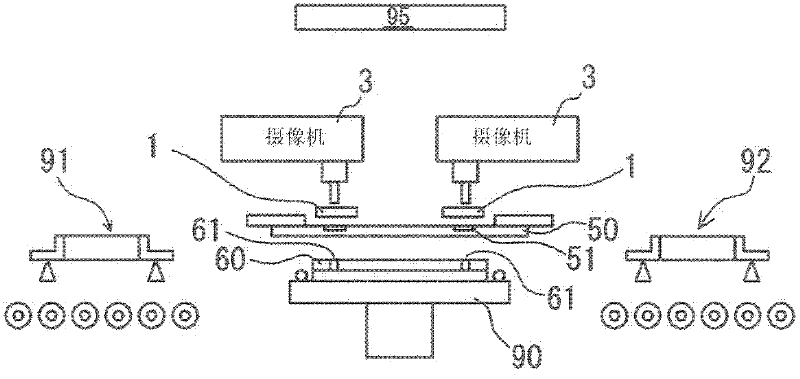

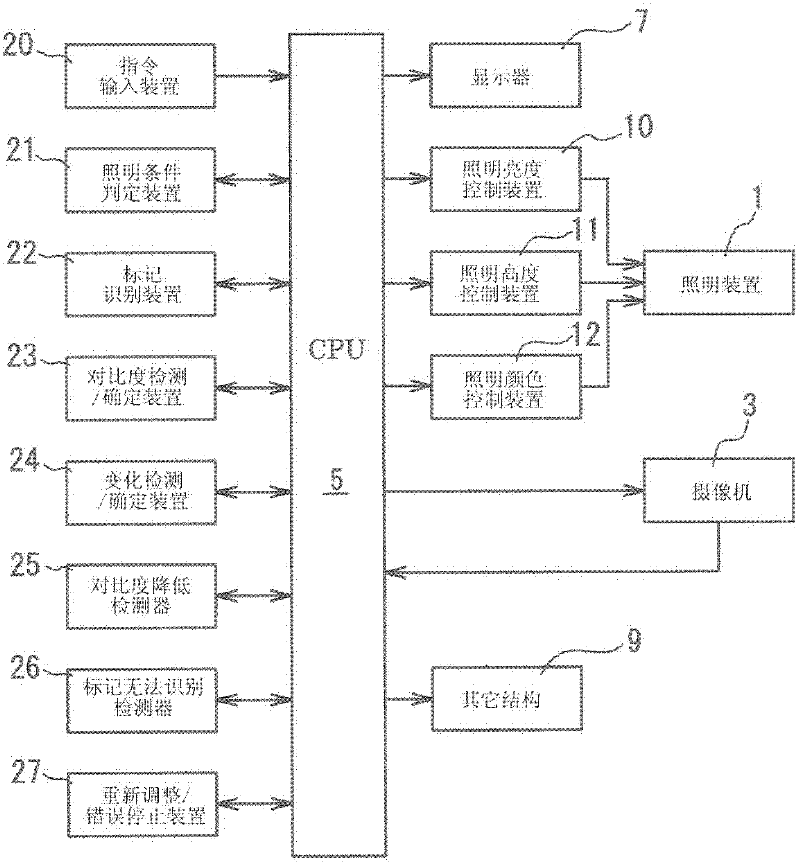

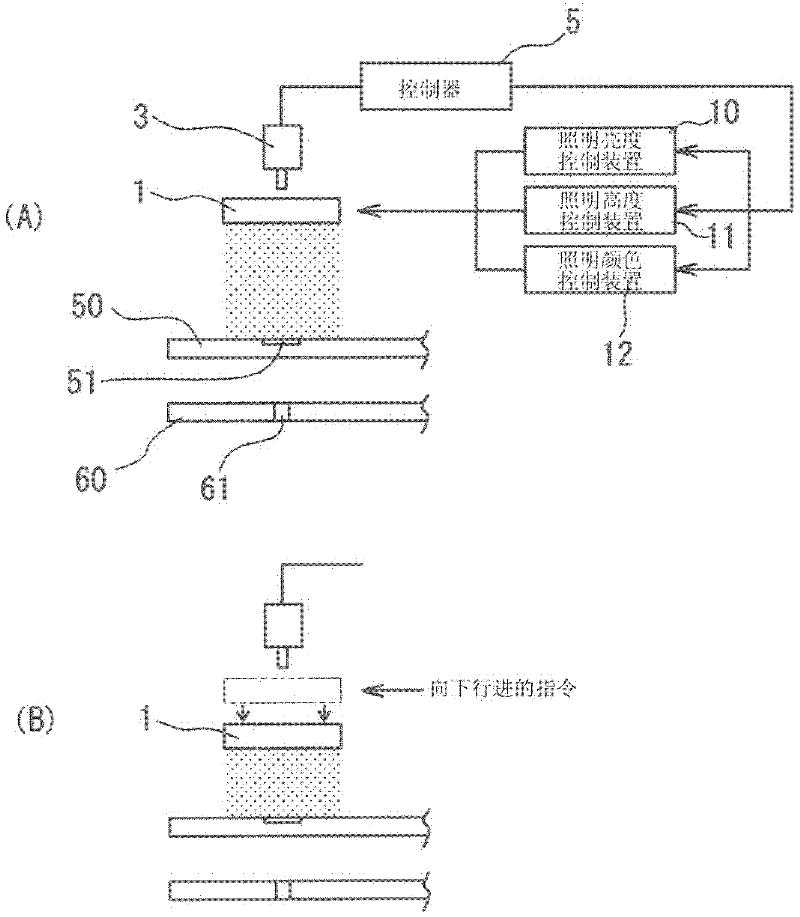

[0027] Hereinafter, the present invention will be described in detail with reference to the accompanying drawings. figure 1 An overview of an exposure apparatus used to manufacture printed circuit boards is shown. figure 2 shows the block diagram, while image 3 Details of the lighting device 1 are shown.

[0028] The pattern drawn on the mask 50 is used by the light source 95 to expose the printed circuit board 60 carried on the exposure table 90 by the loading device 91, and then the printed circuit board 60 is transferred to the next process by the carrying device 92. .

[0029] Four CCD cameras 3 are disposed above the mask 50 at positions corresponding to the four corners of the printed circuit board 60 . Before exposure, alignment between the mask 50 and the printed circuit board 60 is performed using the mask marks 51 drawn on the corners of the mask 50 and the board marks 61 formed on the corners of the printed circuit board 60. allow. The exposure stage 90 can m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com