Manufacturing method of interconnection structure

A manufacturing method and interconnection structure technology, applied in the direction of electrical connection formation of printed components, etc., can solve the problems of poor electrical signal transmission performance and unsatisfactory reliability of printed circuit boards, etc., to improve electrical performance, reduce stress, Avoid the effect of separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

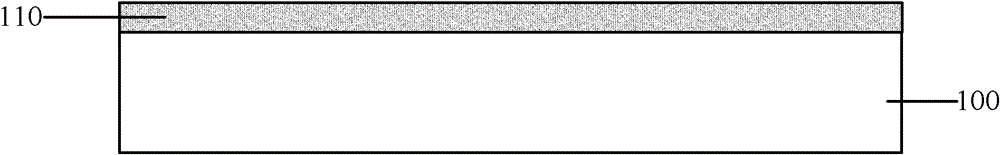

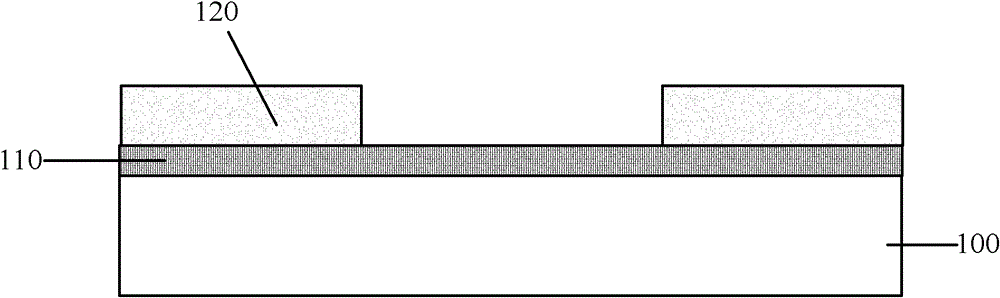

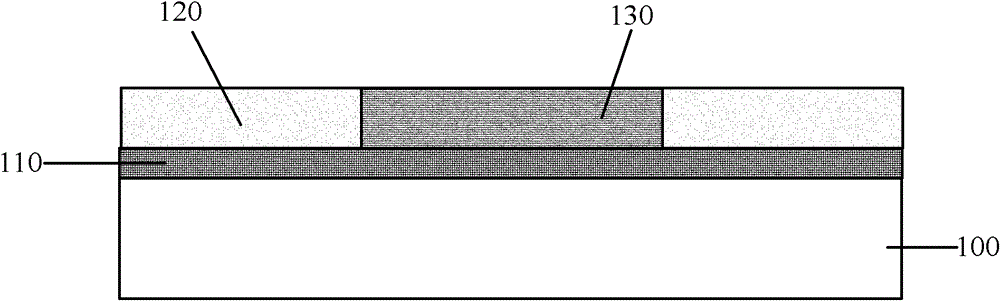

[0042] The reliability of the existing printed circuit board is not high, and the performance of electric signal transmission is not good, and the existing printed circuit board has the problem of open circuit. The above-mentioned problems are caused by the internal stress of the interconnect structure of the printed wiring board. Specifically, since the interconnection structure of the printed circuit board includes alternate arrangements of substrate pads, conductive layers, and conductive bumps, wherein the conductive layer is a copper layer made by chemical vapor deposition, and the substrate pads and conductive bumps are The copper layer produced by the electroplating deposition process, due to the stress between the copper layer deposited by chemical vapor deposition and the copper layer deposited by electroplating, makes the connection between the copper layer deposited by chemical vapor phase and the copper layer deposited by electroplating unreliable, that is, the cond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com