Machine tool having a protective cover

A technology of machine tools and protective covers, which is applied in the direction of manufacturing tools, metal processing equipment, grinding machines, etc., can solve the problems of difficult implementation of the integral representation of clamping hoops and protective covers, and the cover body exceeds the reliable angle range. Effect of small rupture risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

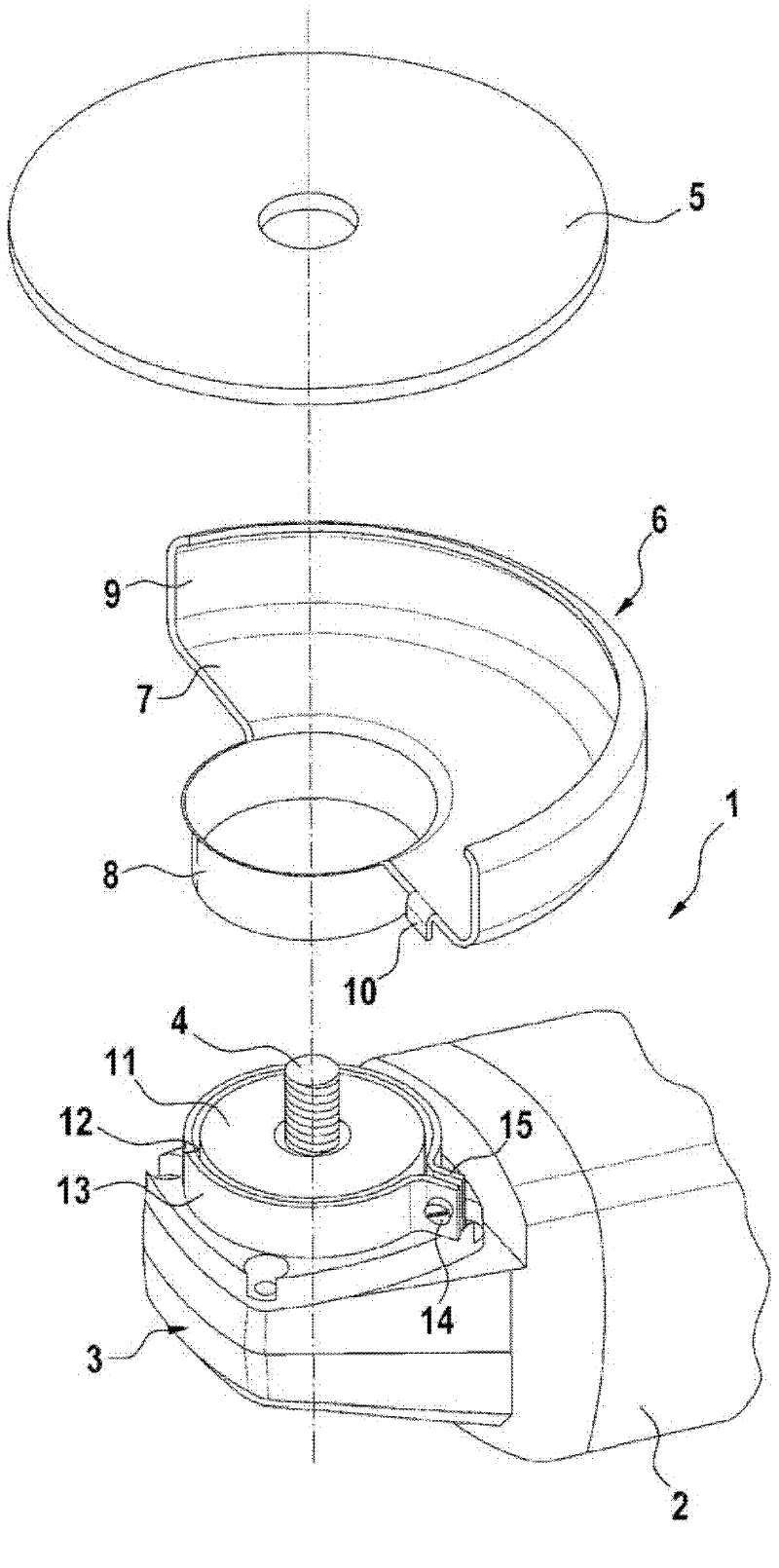

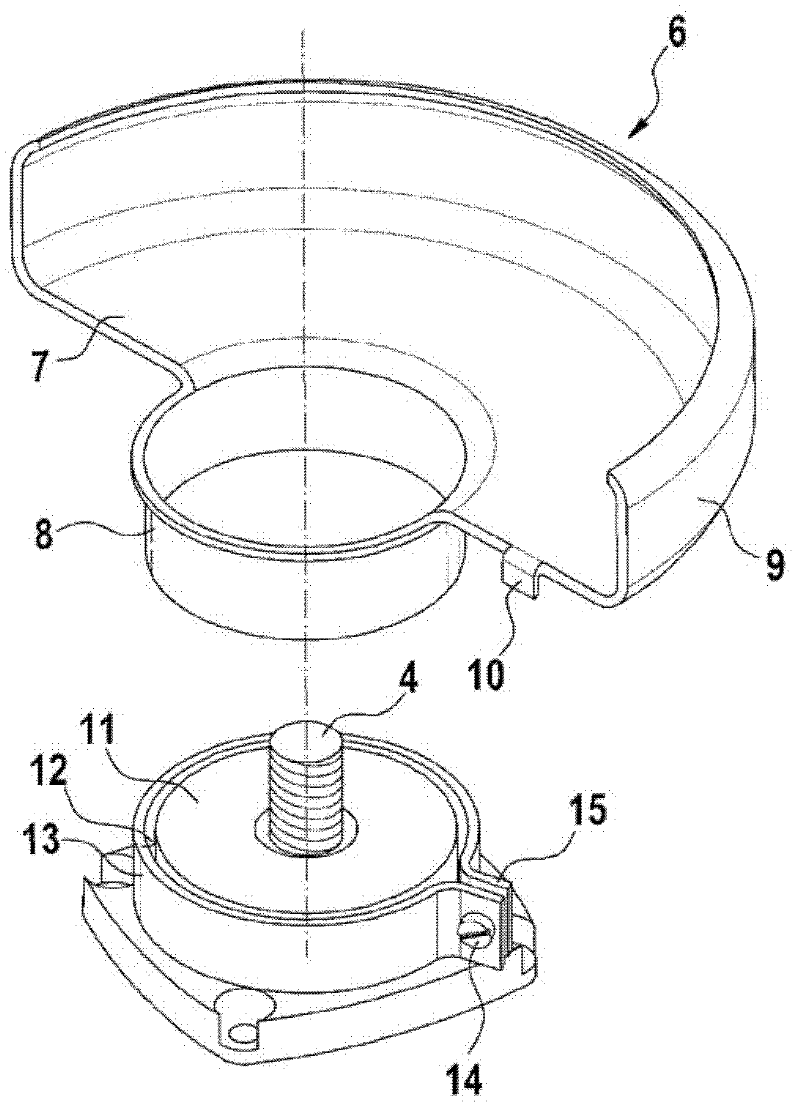

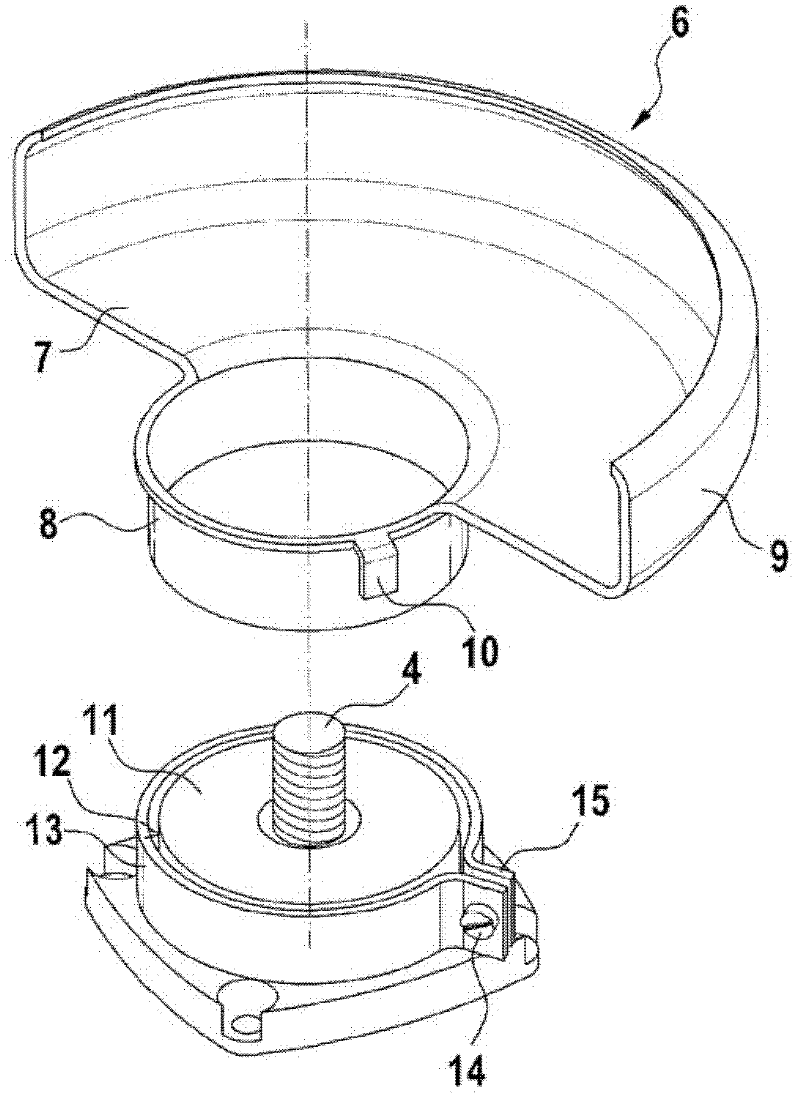

[0031] in figure 1 The hand-held machine tool 1 shown in the figure refers to an angle grinder with an electric drive motor in a housing 2, wherein the drive movement of the electric drive motor is transmitted to the driven shaft 4 perpendicular to the motor shaft through the transmission device 3 Above, the grinding disc 5 constituting the tool can be detachably connected with the driven shaft. The hand-held power tool 1 has a protective cover 6, which includes an at least approximately semicircular cover 7, a clamping flange 8 and a surrounding edge area 9 on the cover 7, which is approximately in the assembled position. Parallel to the grinding disc 5. The cover body 7, the clamping flange 8 and the edge region 9 are formed in one piece. The protective cover 6 is detachably connected to the hand-held power tool 1 via a clamping flange 8.

[0032] An angular (curved) stop element 10 is integrally formed in the area of the end edges of the cover body 7, which stop element is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com