Air-cooled metal separator for fuel cell and fuel cell stack using same

A fuel cell stack and metal separation technology, which is applied to fuel cell grouping, fuel cell components, fuel cells, etc., can solve the problems of difficulty in making a graphite cooling flow path and increase the stack volume, and achieve effective cooling. Structure, the effect of preventing deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Hereinafter, an air-cooled metal separator plate for a fuel cell according to the present invention and a fuel cell stack using the same will be described in detail with reference to the drawings.

[0030] In the description process, the thickness of the lines or the size of the structural elements shown in the drawings will be exaggerated for the clarity and convenience of the description.

[0031] In addition, the terms used in the present invention are defined in view of their functions in the present invention, and the interpretation of these terms may vary depending on the user's or operator's intention or custom.

[0032] Therefore, the definitions of these terms should be based on the entire contents of this specification.

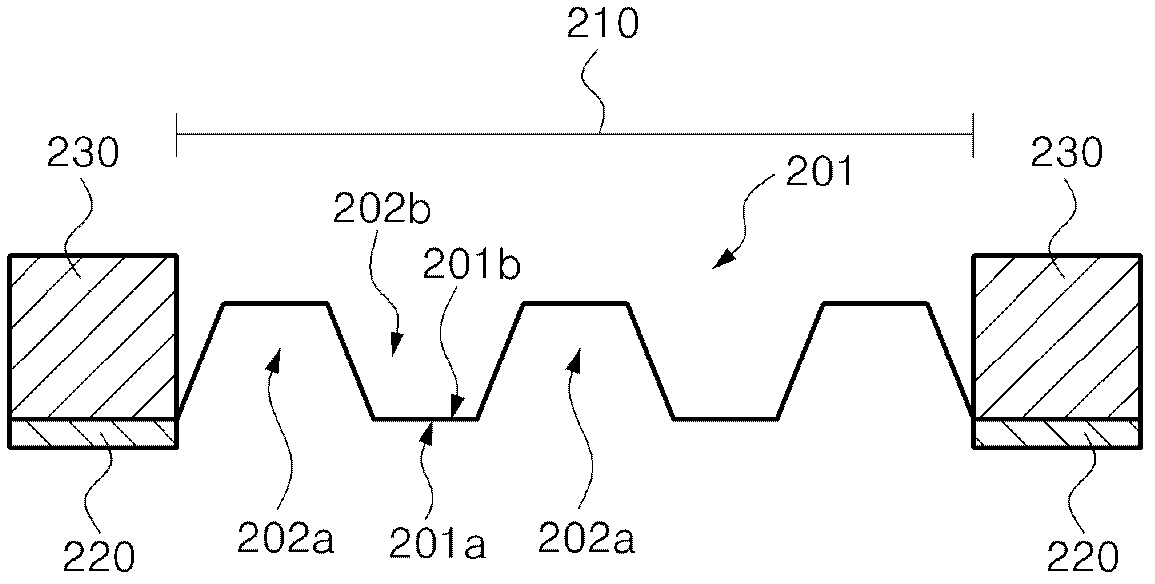

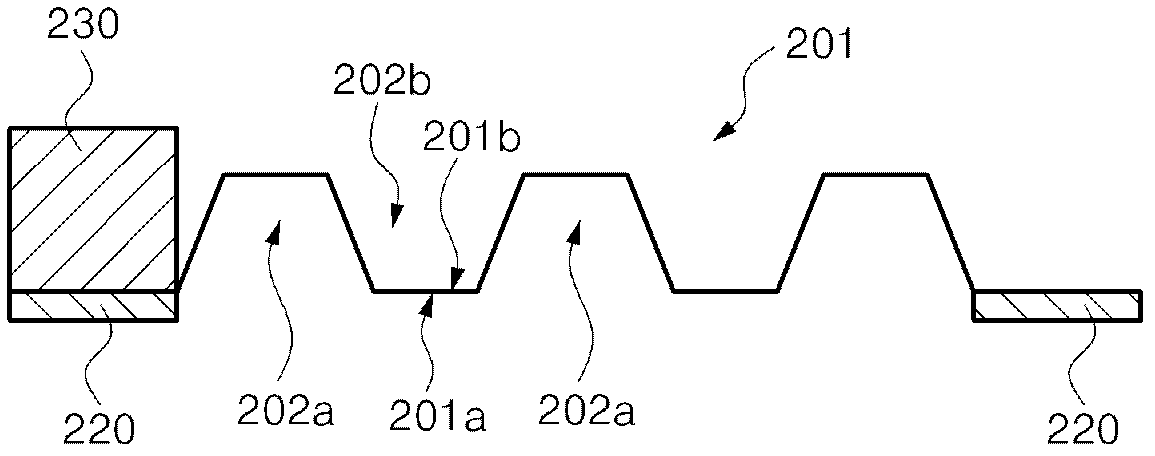

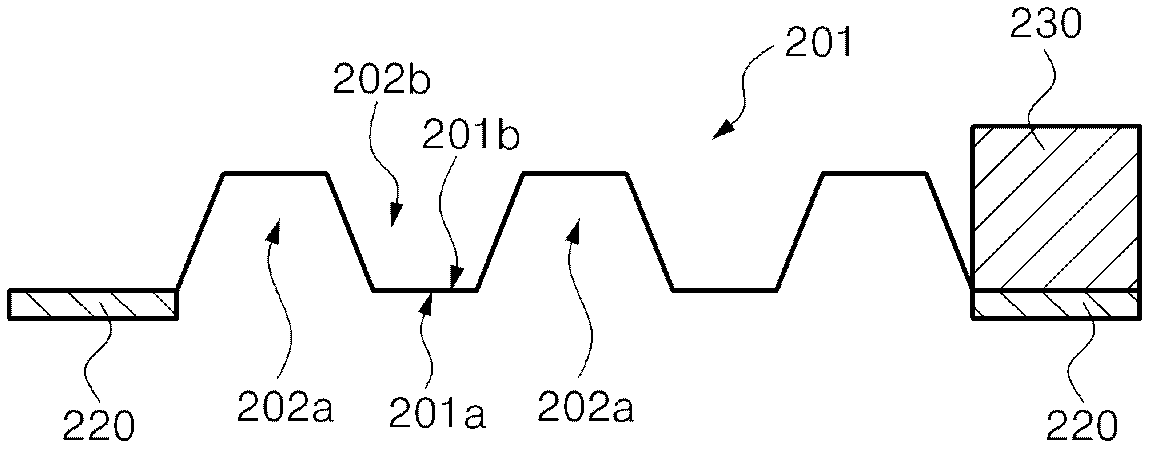

[0033] Figure 1 to Figure 4 An air-cooled metal separator plate for a fuel cell according to an embodiment of the present invention is schematically shown.

[0034] The air-cooled metal separator plate of the present invention includes a ch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com